Preparation method of illite/montmorillonite mixed-layer clay/natural rubber compounded rubber

A technology of illuminator mixed layer and natural rubber, which is applied in the field of performance improvement of composite rubber, can solve the problems of reducing the characteristics of natural rubber, uneven dispersion of inorganic fillers, and failure to achieve reinforcing effects, so as to achieve high chemical resistance and reduce mixing. Refining equipment, good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

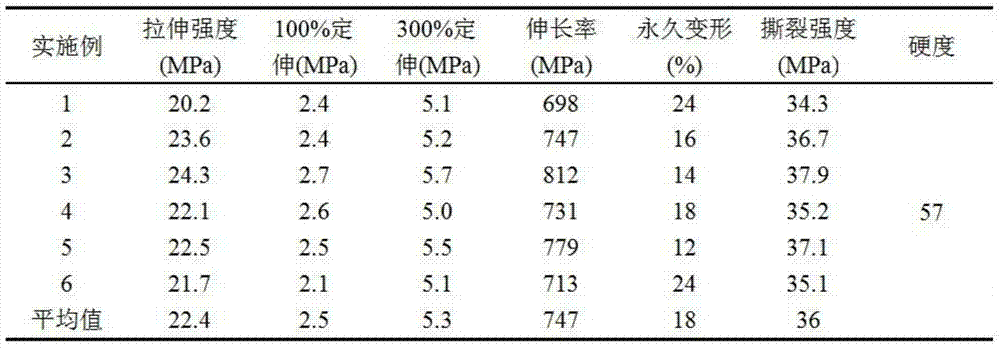

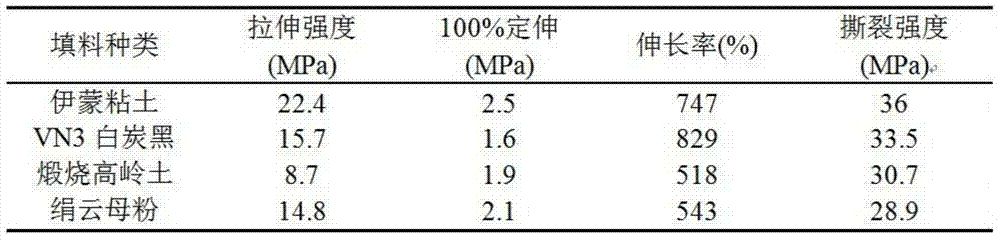

Examples

Embodiment 1

[0034] (1) Slurry preparation: crush the natural I-Monite mixed layer clay into granular materials smaller than 3mm, then soak the crushed materials in water for 8 hours, then add sodium hexametaphosphate as a dispersant, and stir for 2 hours with a sand mill disperser , after finally crossing the 375 mesh sieve, obtain the slurry under the sieve; wherein the solid content of the slurry is 45%, and the addition of sodium hexametaphosphate is 0.5wt% of the solid content of the slurry;

[0035] (2) Chemical bleaching: bleach the slurry obtained in step (1) at 1000rpm and 65°C, specifically: first use HCl solution to adjust the pH value of the slurry to 4, then add hydrosulfite, react for 45 minutes, and then add Oxalic acid, reacted for 45min; after that, the slurry was separated to obtain a yellow solid, and the obtained yellow solid was washed to white, and then water was added to make the solid content of the slurry 45wt%, and the bleached slurry could be obtained; wherein, th...

Embodiment 2

[0042] (1) Slurry preparation: crush the natural imonite mixed layer clay into granular materials smaller than 3mm, then soak the crushed materials in water for 12 hours, then add sodium hexametaphosphate as a dispersant, and stir for 2 hours with a sand mill disperser , after finally crossing the 375 mesh sieve, obtain the slurry under the sieve; wherein the solid content of the slurry is 35%, and the addition of sodium hexametaphosphate is 1.0wt% of the solid content of the slurry;

[0043] (2) Chemical bleaching: bleach the slurry obtained in step (1) at 700rpm and 65°C, specifically: first use HCl solution to adjust the pH value of the slurry to 5, then add hydrosulfite, react for 45min, and then add Oxalic acid, reacted for 45min; after that, the slurry was separated to obtain a yellow solid, and the obtained yellow solid was washed to white, and then water was added to make the solid content of the slurry 45wt%, and the bleached slurry could be obtained; wherein, the additi...

Embodiment 3

[0050] (1) Slurry preparation: crush the natural imonite mixed layer clay into granular materials smaller than 3mm, then soak the crushed materials in water for 12 hours, then add sodium hexametaphosphate as a dispersant, and stir for 4 hours with a sand mill disperser , after finally crossing the 375 mesh sieve, obtain the slurry under the sieve; wherein the solid content of the slurry is 30%, and the addition of sodium hexametaphosphate is 1.0wt% of the solid content of the slurry;

[0051] (2) Chemical bleaching: bleach the slurry obtained in step (1) at 1000rpm and 65°C, specifically: first use HCl solution to adjust the pH value of the slurry to 5, then add hydrosulfite, react for 60 minutes, and then add Oxalic acid, reacted for 60min; then separated the slurry to obtain a yellow solid, washed the obtained yellow solid to white, then added water to make the solid content of the slurry 45wt%, and then obtained the bleached slurry; wherein, the addition of hydrosulfite Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com