Method for improving mechanical property of cellulose acetate

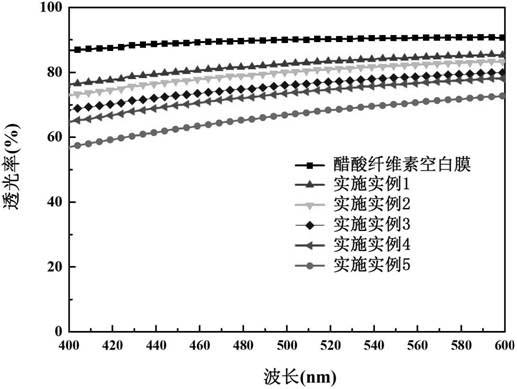

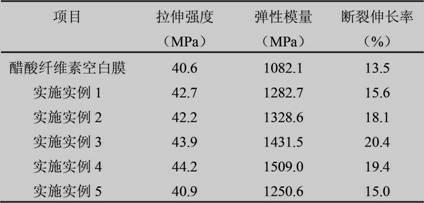

A technology of cellulose acetate and nanocellulose, which is applied in the field of polymer material preparation and application, can solve the problems of poor performance index and decreased light transmittance, achieve high Young's modulus, increase tensile strength, and improve acetic acid Effects of cellulose mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Surface acetification of nanocellulose whiskers

[0027] (1) Preparation of nanocellulose whisker slurry

[0028] Immerse 20 g of cellulose in a sulfuric acid solution with a concentration of 64%, with a liquid-solid ratio of 17.5 mL / g, stir and react in a water bath at 45°C for 20 min, dilute with water to stop the reaction, and obtain a reaction solution A1. The reaction solution A1 was centrifuged, and the supernatant was removed. Centrifuge and wash with water twice, and replace with glacial acetic acid to obtain nanocellulose whisker slurry B1.

[0029] (2) Acetate on the surface of nanocellulose whiskers

[0030] 1) Mix 4g of slurry B1 and 10g of glacial acetic acid evenly to obtain slurry C1;

[0031] 2) Make slurry C1 swell at 40°C for 15 minutes and then cool to room temperature;

[0032] 3) Add a mixed solution of 0.01 g of sulfuric acid, 0.2 g of acetic anhydride and 3 g of glacial acetic acid to the cooled slurry C1 to obtain a mixed solution D1;

[...

Embodiment 2

[0039] 1. Surface acetification of nanocellulose whiskers

[0040] (1) Preparation of nanocellulose whisker slurry

[0041] Immerse 20 g of cellulose in a sulfuric acid solution with a concentration of 64%, with a liquid-solid ratio of 17.5 mL / g, stir and react in a water bath at 45°C for 20 min, dilute with water to stop the reaction, and obtain a reaction solution A2. The reaction solution A2 was centrifuged, and the supernatant was removed. Centrifuge and wash with water twice, and then replace with glacial acetic acid to obtain nanocellulose whisker slurry B2.

[0042] (2) Acetate on the surface of nanocellulose whiskers

[0043] 1) Mix 4g of slurry B2 with 15g of glacial acetic acid to obtain slurry C2;

[0044] 2) Make slurry C2 swell at 35°C for 25 minutes and then cool to room temperature;

[0045] 3) Add a mixed solution of 0.005 g of sulfuric acid, 0.15 g of acetic anhydride and 4 g of glacial acetic acid to the cooled slurry C2 to obtain a mixed solution, and ob...

Embodiment 3

[0052] 1. Surface acetification of nanocellulose whiskers

[0053] (1) Preparation of nanocellulose whisker slurry

[0054] Immerse 20 g of cellulose in a sulfuric acid solution with a concentration of 64%, with a liquid-solid ratio of 17.5 mL / g, stir and react in a water bath at 45°C for 20 min, dilute with water to stop the reaction, and obtain a reaction solution A3. The reaction solution A3 was centrifuged, and the supernatant was removed. Centrifuge and wash with water twice, and then replace with glacial acetic acid to obtain nanocellulose whisker slurry B3.

[0055] (2) Acetate on the surface of nanocellulose whiskers

[0056] 1) Mix 4g of slurry B3 with 13g of glacial acetic acid to obtain slurry C3;

[0057] 2) Make slurry C3 swell at 50°C for 20 minutes and then cool to room temperature;

[0058] 3) Add a mixed solution of 0.008 g of sulfuric acid, 0.6 g of acetic anhydride and 5 g of glacial acetic acid into the cooled slurry C3 to obtain a mixed solution D3;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com