Polymer/montmorillonite-gallicin nano-antibacterial composite material and its preparation method

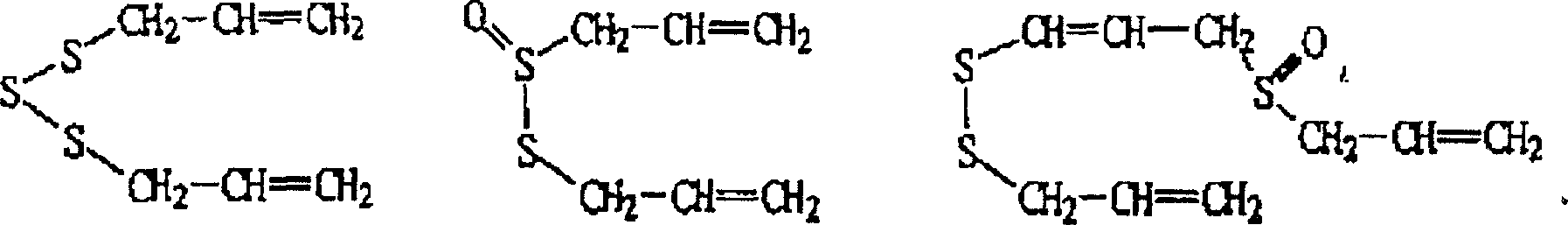

A composite material and montmorillonite technology are applied in the field of polymer/montmorillonite-allicin nano-antibacterial composite materials and their preparation, and can solve the problems of poor heat resistance of allicin, instability of allicin, and loss of function of decomposition, etc. To achieve the effect of not easy to drug resistance, safe to eat, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

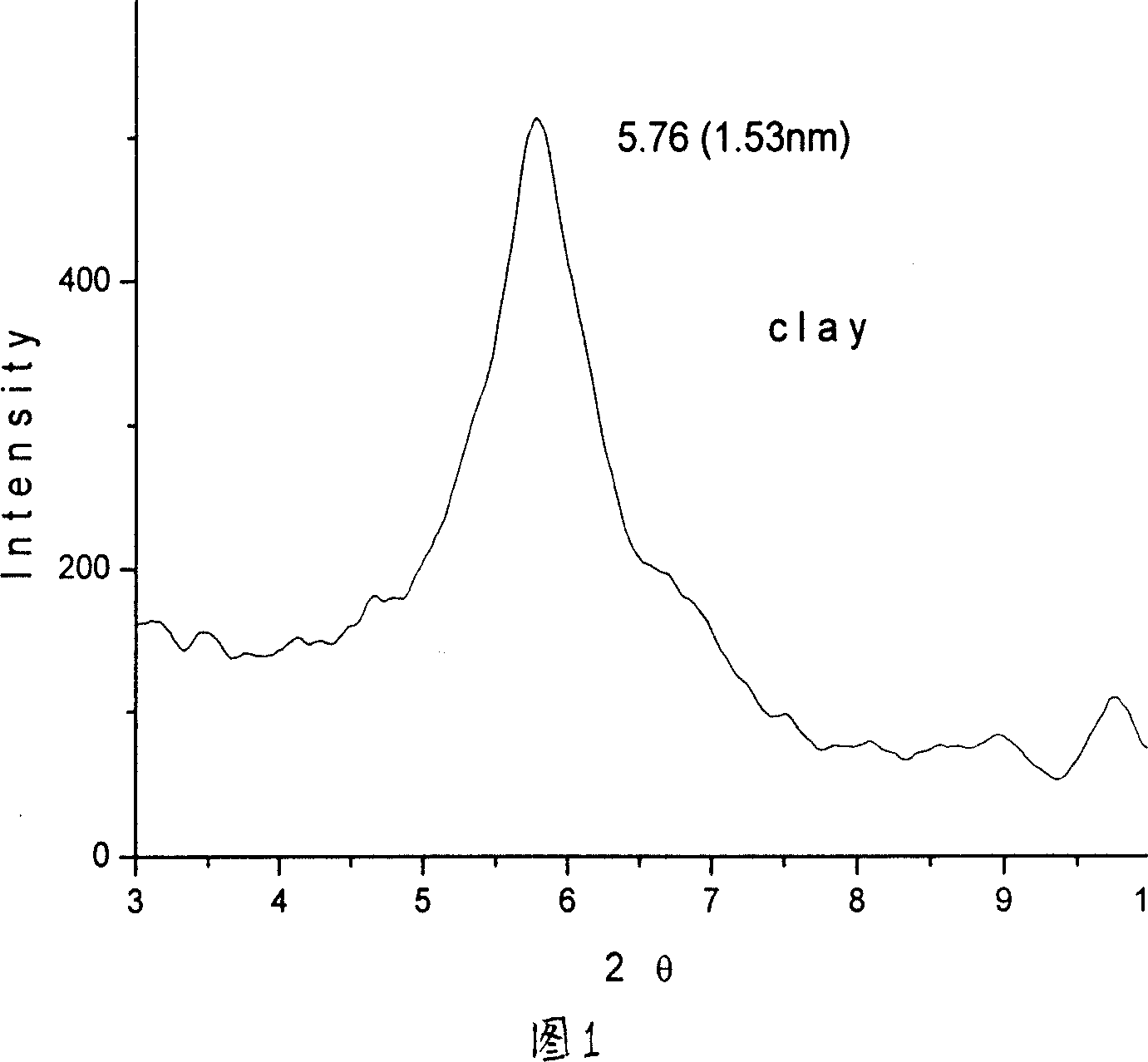

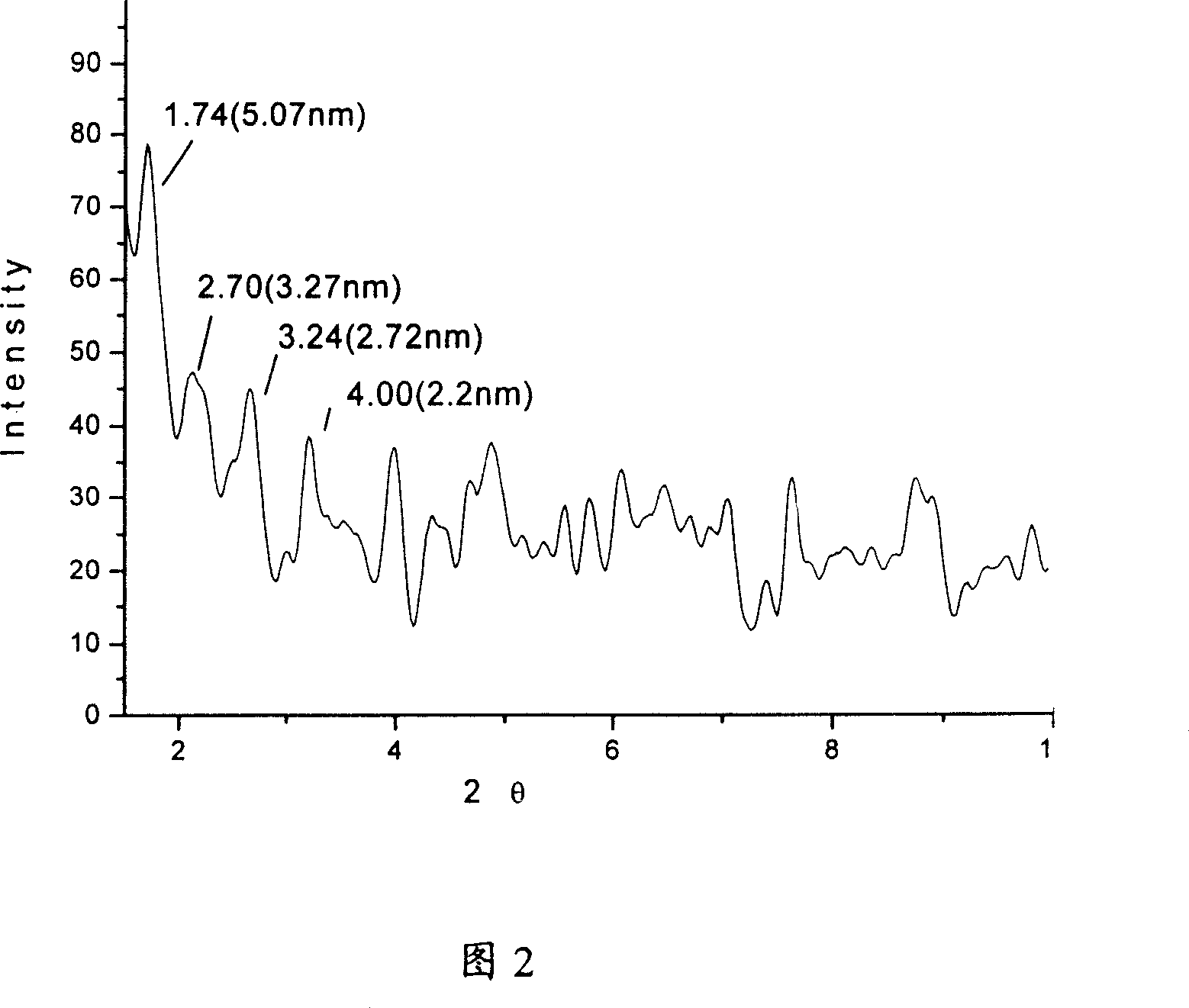

[0053] Dissolve 0.1 part of montmorillonite in 20 mL of aqueous solution, stir and disperse at high speed for 20 minutes, add 0.3 part of antibacterial allicin into the dispersed montmorillonite colloid solution at 20-75 °C, React at low temperature for 1 hour to obtain a flocculent precipitate; filter and wash the precipitate; vacuum-dry at 60°C for 24 hours, and the resulting solid is crushed to form a functional montmorillonite-allicin antibacterial complex

[0054] Disperse 0.1 part of the above-mentioned functional montmorillonite-allicin antibacterial compound in 100 parts of toluene at 20-60 °C, add it into 100 parts of room temperature vulcanized silicone rubber, disperse it ultrasonically for 0.5 min, make it fully mixed, add orthosilicone 1 part of ethyl acetate, 0.1 part of dibutyltin dilaurate, and 0.5 part of dibutyltin dilaurate are coated on the mold, and placed at 20-60° C. for at least 0.2-24 hours to obtain the polymer / montmorillonite-garlicin nanometer antiba...

Embodiment 2

[0056] Dissolve 10 parts of montmorillonite in 500 mL of ethanol solution, stir and disperse at high speed for 2 hours, add 20 parts of antibacterial allicin into the dispersed montmorillonite colloid solution at 20-75 °C, React at ℃ for 0.5h to obtain a flocculent precipitate; filter and wash the precipitate; vacuum dry at 60℃ for 24h, and the obtained solid is crushed to become a functional montmorillonite-allicin antibacterial complex

[0057] Disperse 10 parts of the above-mentioned functional montmorillonite-garlicin antibacterial compound in 200 parts of toluene at 20-60 ° C, add 100 parts of room temperature vulcanized silicone rubber, disperse by ultrasonic for 10 minutes, make it fully mixed, add orthosilicic acid 10 parts of ethyl ester and 1 part of dibutyltin dilaurate are coated on the mould, and placed at 20-60° C. for at least 0.2-24 hours to obtain the polymer / montmorillonite-garlicin nanometer antibacterial composite material.

Embodiment 3

[0059] Dissolve 2 parts of montmorillonite in 10mL of aqueous solution, stir and disperse at high speed for 0.5h, add 1 part of antibacterial allicin at 20-75°C to the dispersed montmorillonite colloidal solution, React at ℃ for 1 hour to obtain a flocculent precipitate; filter and wash the precipitate; vacuum dry at 60℃ for 24 hours, and the obtained solid is crushed to form a functional montmorillonite-garlicin antibacterial complex

[0060] Disperse 3 parts of the above-mentioned functional montmorillonite-garlicin antibacterial compound in 100 parts of xylene at 20-60 °C, add it into 100 parts of room temperature vulcanized silicone rubber, disperse it ultrasonically for 2 minutes, make it fully mixed, add orthosilicone 2 parts of ethyl acetate and 2 parts of dibutyltin dilaurate are coated on the mould, and placed at 20-60° C. for at least 0.2-24 hours to obtain the polymer / montmorillonite-garlicin nanometer antibacterial composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com