Method for producing medium-chain-length polyhydroxyalkanoates by virtue of excess activated sludge

A technology of polyhydroxyalkanoate and residual activity, which is applied in the direction of fermentation, etc., to achieve the effect of large application prospects, easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

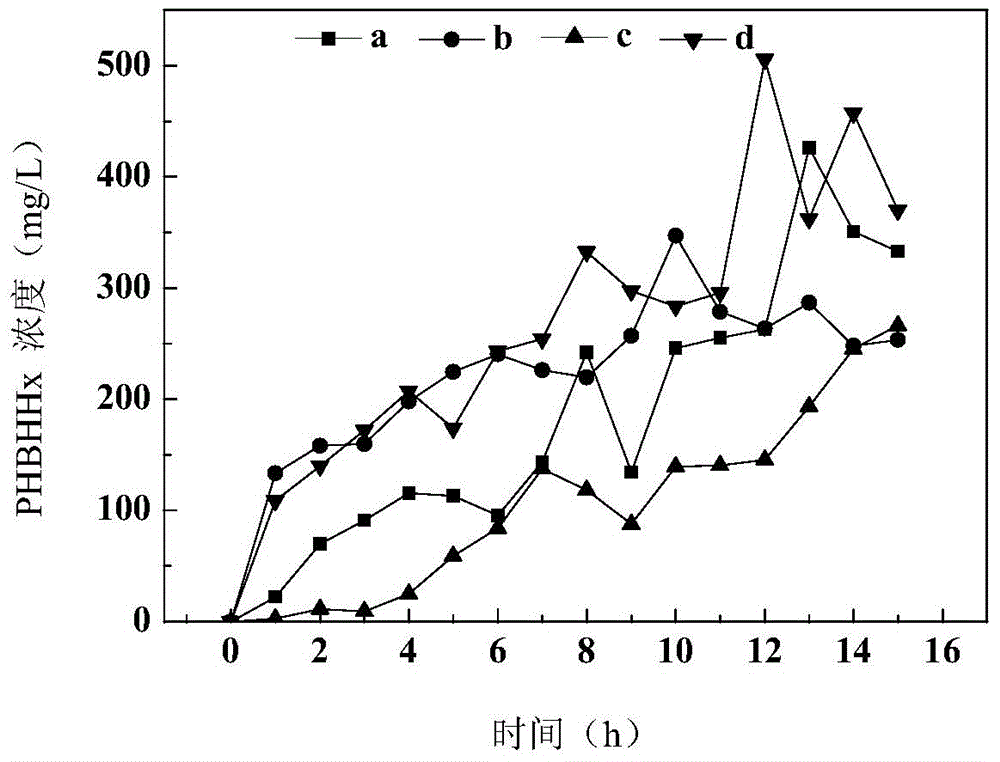

[0019] Example 1: Effects of nitrogen and phosphorus sources on the accumulation of PHBHHx in activated sludge when carbon sources are added in stages

[0020] Use a 1L batch reactor, continuously aerate 2L / min from the aeration head, without stirring, and react for 16h at a temperature of 30°C. Under the condition that the total carbon source is kept at 1.5g / L sodium laurate, 0.5g sodium laurate is added at the 0th, 4th, and 8th hours, respectively. The concentration conditions of nitrogen source and phosphorus source in the four batch experiments are as follows: ( a) Nitrogen and phosphorus, NH 4 Cl, 0.16g / L+K 2 HPO 4 , 0.092g / L; (b) with nitrogen and phosphorus deficiency, NH 4 Cl, 0.16g / L+K 2 HPO 4 , 0g / L; (c) nitrogen deficiency with phosphorus, NH 4 Cl, 0g / L+K 2 HPO 4 , 0.092g / L; (d) nitrogen deficiency and phosphorus deficiency, NH 4 Cl, 0g / L+K 2 HPO 4 , 0g / L. from figure 1 It can be seen from (d) that the concentration of PHBHHx is the highest under the co...

Embodiment 2

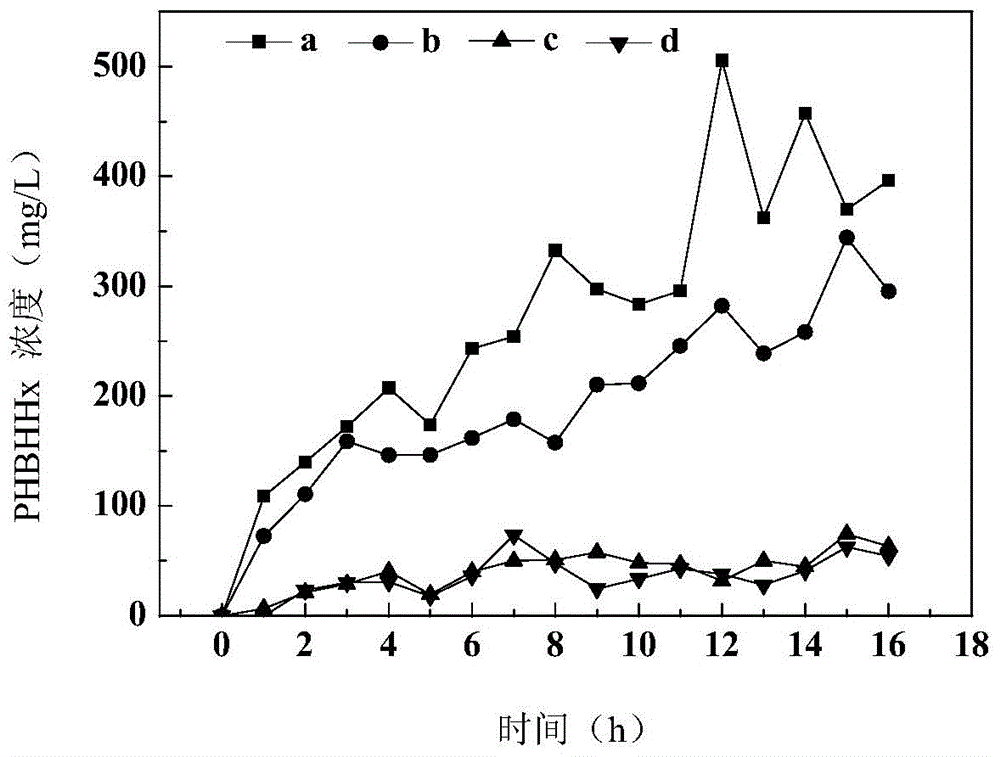

[0021] Example 2: Influence of different aeration methods on the accumulation of PHBHHx in activated sludge under the condition of nitrogen deficiency and phosphorus deficiency

[0022] Using a 1L batch reactor, under the condition that the total carbon source is 1.5g / L sodium laurate, 0.5g sodium laurate was added at the 0th, 4th and 8th hours, respectively, for nitrogen deficiency and phosphorus deficiency, namely NH 4 Cl 0g / L+K 2 HPO 4 0g / L, reaction 16h, temperature 30 ℃. The aeration conditions in the four batch experiments were as follows: (a) continuous aeration; (b) 60min aeration + 30min stirring; (c) 60min aeration + 60min stirring; (d) 120min aeration + 120min stirring. Keep the aeration volume at 2L / min during aeration, and stop the aeration during stirring. from figure 2 It can be seen from (a) that the concentration of PHBHHx during continuous aeration is the highest under the conditions of the four batches. At this time, the concentrations of PHB, PHHx and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com