Copolymer and cosmetic material composition

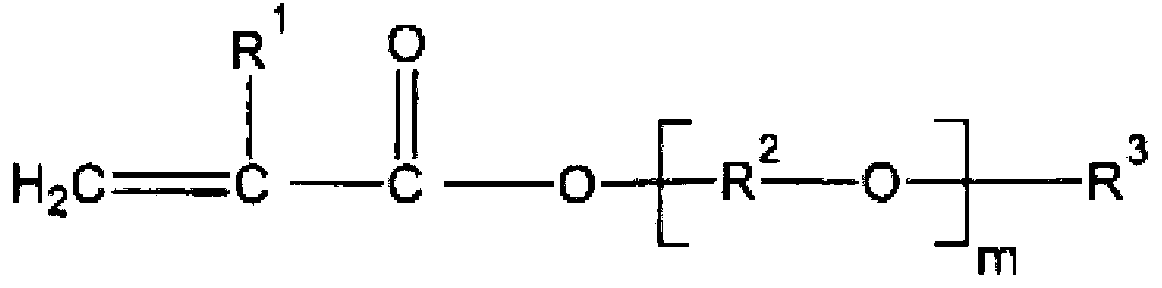

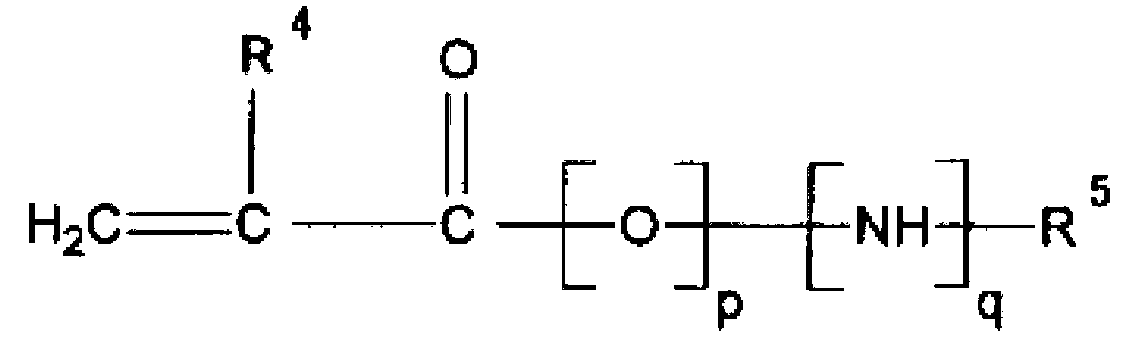

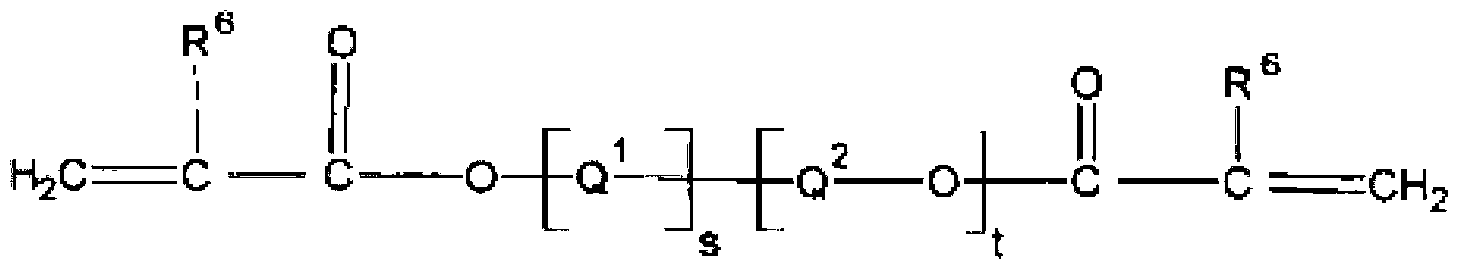

A technology of copolymer and general formula, applied in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of inability to prepare preparations, difficulty in emulsification, and poor touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~3

[0320][production of copolymer]

[0321]

[0322] In the reactor that reflux condenser, dropping funnel, thermometer, nitrogen inlet pipe and stirring device are installed, add ethanol 100 weight parts and monomer (C) (ethylene glycol dimethyl Monomers (49.5 parts by weight of methoxypolyoxyethylene (23 moles) methacrylate, 25 parts by weight of tert-butyl methacrylate, 25 parts by weight of stearyl methacrylate) other than the The apparatus was replaced with nitrogen and then heated to 84°C. After putting 0.2 part by weight of dimethyl 2,2'-azobis(2-methylpropionate) into the reactor, it was stirred under heating at 84°C for 3 hours. Then, 300 parts by weight of water was added, and the reactor was kept at 84°C and stirred for 1 hour. Then, 0.5 parts by weight of ethylene glycol dimethacrylate was dissolved in 4 parts by weight of ethanol and put into the reactor, and then, 2,2'-azobis(2-methylpropane Acid) dimethyl ester 0.3 weight part, carried out stirring for 3 hours...

Embodiment 11~17、 comparative example 4~6

[0402] [production of copolymer]

[0403]

[0404] Add 100 parts by weight of ethanol and the monomers shown in Table 5 to a reactor equipped with a reflux condenser, a dropping funnel, a thermometer, a nitrogen gas introduction pipe and a stirring device, replace the reactor with nitrogen, and then heat to 84°C. After charging 0.2 parts by weight of dimethyl 2,2'-azobis(2-methylpropionate) into the reactor, it was stirred under heating at 84°C for 4 hours. Then, 0.3 parts by weight of dimethyl 2,2'-azobis(2-methylpropionate) was charged into the reactor twice and stirred for 4 hours to obtain a copolymer (2-1).

[0405]

[0406] Except using the monomers described in Table 5, copolymers (2-2) to (2-5), copolymers (2-8) to (2 -10).

[0407]

[0408] 87.2 parts by weight of ethanol and the monomers shown in Table 5 were added to a reactor equipped with a reflux condenser, dropping funnel, thermometer, nitrogen gas introduction pipe and stirring device, and the reactor w...

Embodiment 18~19、 comparative example 7~9

[0477]

[0478] Using 49.5 parts by weight of methoxypolyoxyethylene (15 moles) methacrylate to replace 49.5 parts by weight of methoxypolyoxyethylene (23 moles) methacrylate of copolymer (1-1), in addition , Copolymer (3-1) was produced in the same manner as Copolymer (1-1).

[0479]

[0480] Using 49.5 parts by weight of methoxypolyoxyethylene (40 moles) methacrylate to replace 49.5 parts by weight of methoxypolyoxyethylene (23 moles) methacrylate of copolymer (1-1), in addition , Copolymer (3-2) was produced in the same manner as Copolymer (1-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com