Comb

A technology of combs and combs, applied in the field of hair combing tools, can solve problems affecting combing, cumbersome production process, and low production efficiency, and achieve the effects of avoiding waste of resources, reducing production costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

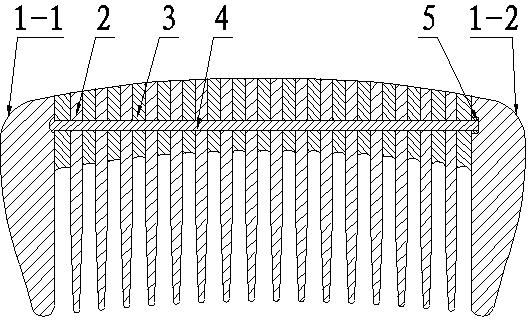

[0034] see figure 1 , Figure 6 and Figure 7 : The present invention includes two auxiliary teeth (1-1, 1-2) and sixteen comb teeth 2, between the auxiliary teeth (1-1, 1-2) and the comb teeth 2 and between the comb teeth 2 and the comb teeth A spacer 3 is arranged between the two, and the sixteen comb teeth 2 and the auxiliary teeth on both sides of the comb tooth 2 are separated by the spacer 3 . The cross-sections of the comb teeth 2 and the spacer 3 are similar to rectangles. What is different from the rectangle is that the four corners of the comb teeth 2 are rounded, and the two sides of the spacer 3 are respectively provided with recessed miniature arc grooves. 3 and the adjacent comb teeth 2 form a "U"-shaped guide groove. A through hole is provided at the root of the comb teeth 2 and the spacer 3, and the metal bolt 4 passes through the through hole on the comb tooth 2 and the spacer 3, and sixteen comb teeth 2 and seventeen spacers 3 are connected in series to fo...

Embodiment 2

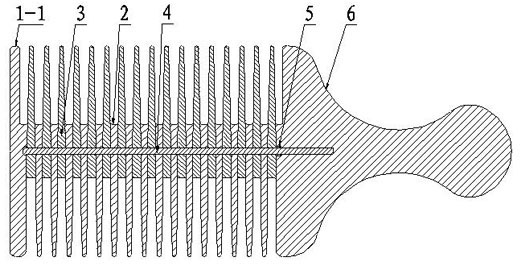

[0039] see figure 2: the present invention is different from embodiment one in that the back side of the partition 3 protrudes from the back of the comb, forming a row of comb teeth on the back side of the back of the comb. Cause the both sides of the back of the comb to form a row of comb teeth respectively, the comb teeth on both sides are spaced apart from each other, and each other is the spacer of the other side, and is also a comb tooth respectively. Its structure is like a grate, and the middle beam is exactly the comb described in embodiment one. back. In addition, a handle 6 is provided on the end face of the comb, which is convenient to hold. The end face of the handle 6 facing the comb teeth is equal to the auxiliary teeth 1-2 in the first embodiment. One end of metal bolt 4 penetrates in the handle 6, and the structure is firmer.

Embodiment 3

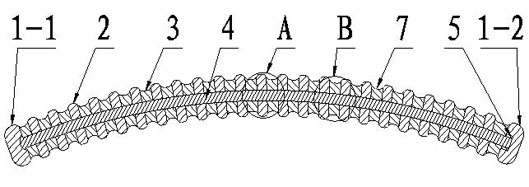

[0041] see image 3 , Figure 4 and Figure 5 Summary of the invention: the present invention breaks the structure that traditional wooden, stone and horny combs can only be made into a flat shape, and increases the comb function and style. The specific method is to make the cross-section of the comb into an arched structure, similar to a hairpin. The cross-section of the comb teeth 2 and the spacer 3 of the arched comb is approximately trapezoidal, and the two end faces of the comb teeth 2 are different from the trapezoidal shape. The two end faces of the spacer 3 are respectively provided with a rounded corner structure, and the two end surfaces of the spacer 3 are respectively provided with recessed miniature arc grooves, and a "U" shape guide groove 7 is formed between the spacer 3 and the adjacent comb teeth 2 . The small ends of the comb teeth 2 and the spacers 3 face inward, towards the center O of the arch, and the large ends face outward. The angle between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com