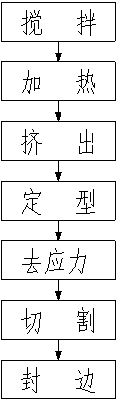

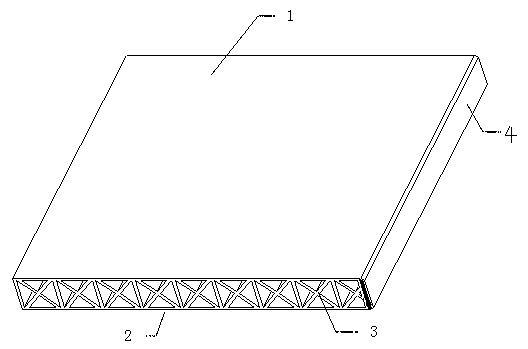

Process for molding hollow plastic building template

A technology of construction formwork and forming process, which is applied in the field of construction formwork, can solve the problems of unguaranteed service life of the formwork, shorten the service life of the formwork, increase the weight of the formwork, etc., so as to increase the shaping effect and service life, increase the service life, and use Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Acute heat treatment, first irradiate the template by using fluorescent lamps, the irradiation time is controlled within 2 minutes, and then the irradiated template is leveled in 3 areas by mirror rollers, and the leveling time is controlled within 2 minutes. Six groups of mirrors are used. The temperature of the roller is controlled at 80°C in the high temperature zone and 40°C in the low temperature zone. After the rapid heat treatment, the leveled template is quenched in the chiller. The temperature of the cooling water is controlled at -5°C, and the cooling time is controlled at 2 minutes. .

[0039] Edge banding treatment, that is, to carry out edge banding treatment on the cut template on the automatic linear edge banding machine, including the following steps: edge trimming pre-milling, edge banding conveying, edge trimming hot melting, glue coating, edge banding, edge banding Cutting off, front and rear trimming, rough trimming, finishing trimming, edge scraping...

Embodiment 2

[0043] Acute heat treatment, firstly, irradiate the template by using fluorescent lamps, and the irradiation time is controlled within 2 to 3 minutes, and then the irradiated template is divided into 4 areas to level the irradiated template through 12 sets of mirror rollers, and the leveling time is controlled within 3 minutes. The temperature of the mirror roll is controlled at 90°C in the high temperature zone and 50°C in the low temperature zone. After the rapid heat treatment, the leveled template is quenched on the chiller, the cooling water temperature is controlled at 10°C, and the cooling time is controlled at 3 minutes.

[0044] Edge banding treatment, the cut template is edge banded on a fully automatic linear edge banding machine, including the following steps: trimming pre-milling, edge banding conveying, trimming hot melt, glue coating, edge banding, edge banding Cutting off, front and rear trimming, rough trimming, finishing trimming, edge scraping, polishing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com