Vehicle functional component

A technology for automobiles and components, applied in the field of functional components for automobiles, can solve problems such as damage to the designability, excellent aesthetics or style, and complex structure of functional components for automobiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

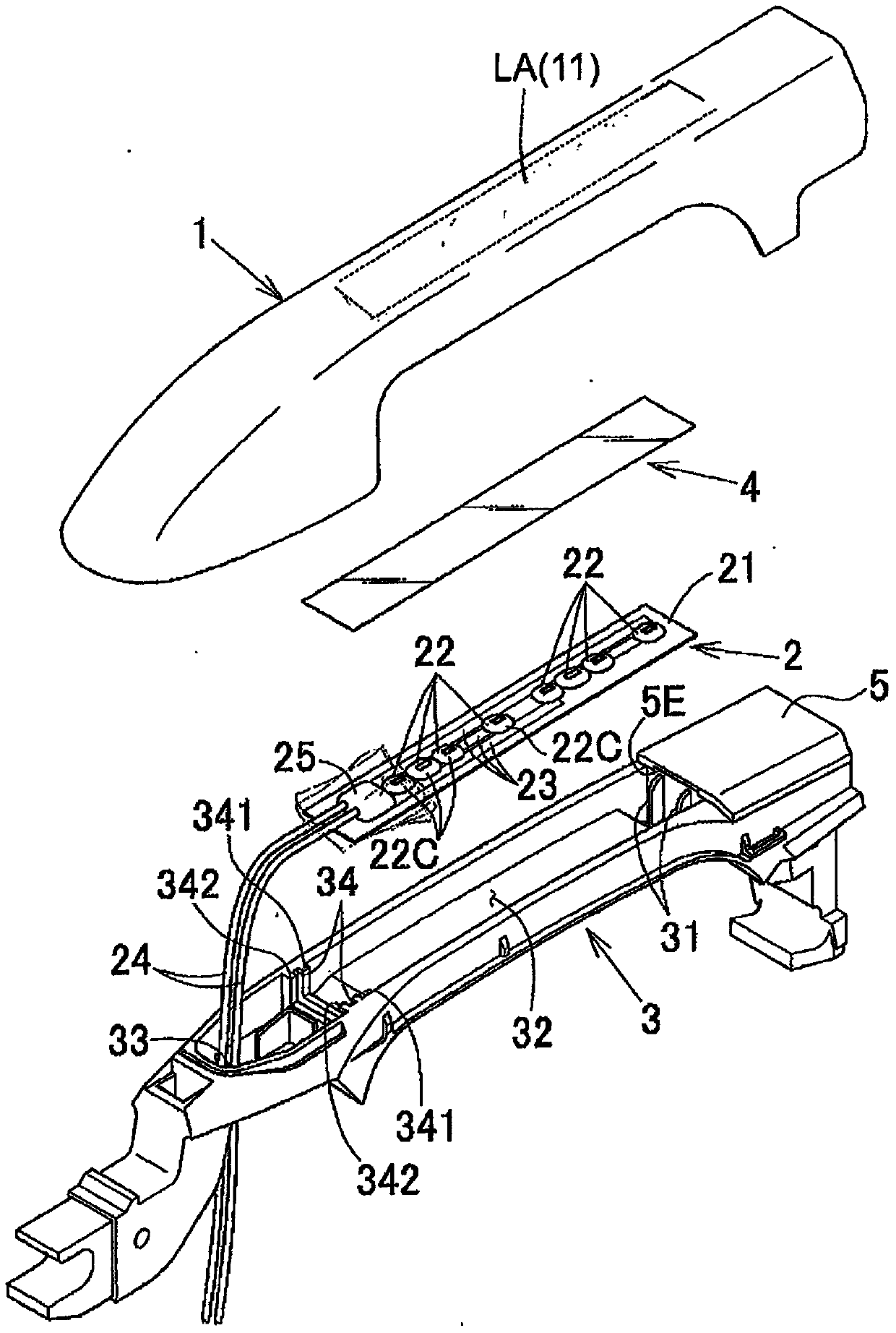

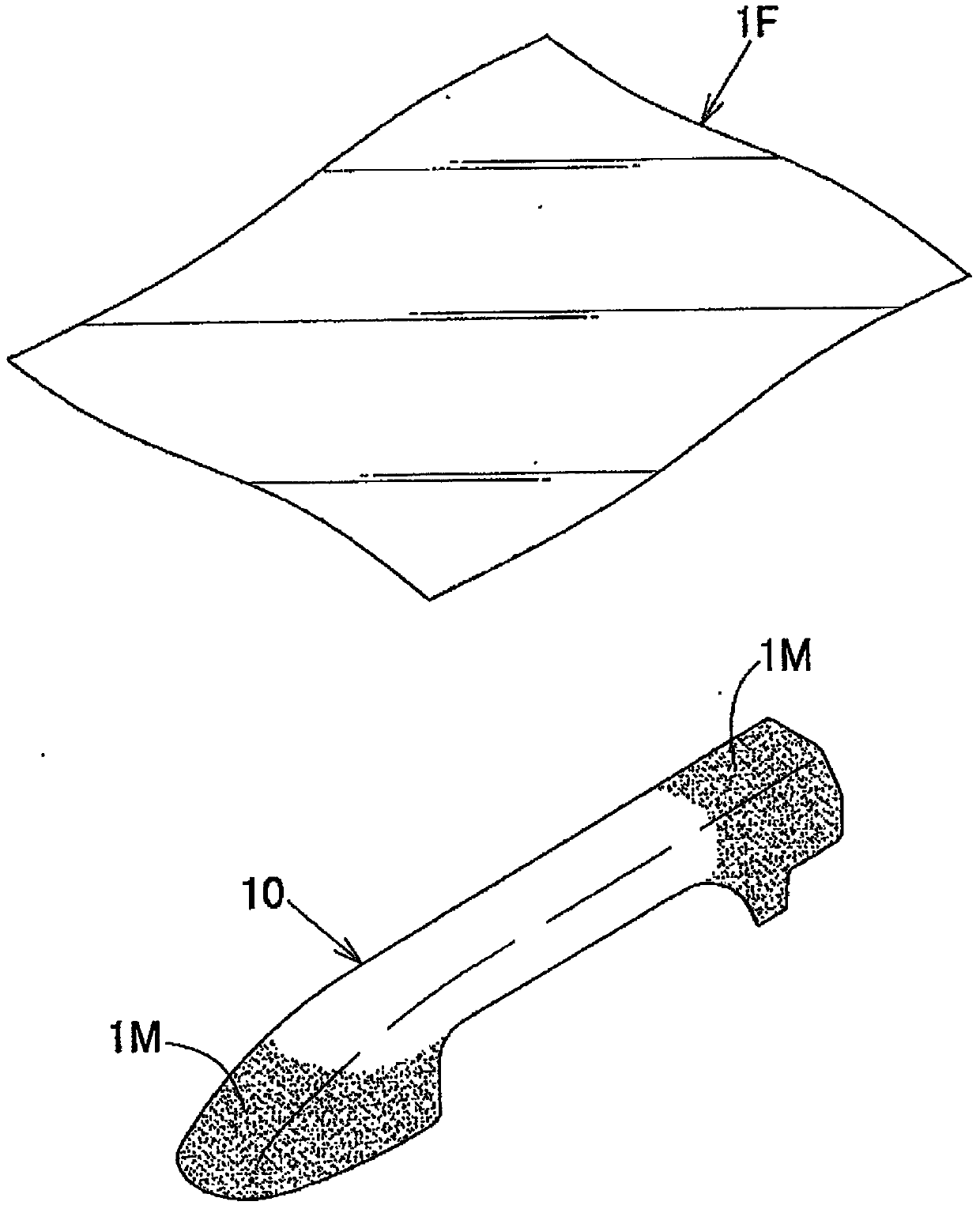

[0059] figure 1 and even Figure 4 The automotive functional part of the first embodiment shown is formed by covering the supporting frame 3 with the molded cover 1 to form the automotive door handle. The door handle is, for example, structured as follows. An electric key K (not shown) for opening and closing is built in the internal storage space 32, and a surface light source 22 composed of LED elements is arranged on the upper surface side of the electric key K. A row of elongated sheet-shaped surface light-emitting elements 2 is provided, and, along the light distribution surface as its upper surface, for example, Figure 4 The light-transmitting film 4 is processed by roughening the surface in a predetermined pattern as shown. The surface light-emitting element 2 and the light-transmitting film 4 have substantially the same shape, and are molded into an elongated rectangle along the doorknob-shaped extended upper surface of the molding cover 1 .

[0060] Here, the surf...

Embodiment 2

[0067] exist Figure 5 In the automotive functional part of the shown embodiment 2, the supporting frame 3 constitutes the automotive reflector in the state covered with the molded cover 1, and the detection part accommodated in the storage space together with the surface light-emitting element 2 detects the user's The opening and closing operation signal of the car door, or the direction indicator light operation signal. Other configurations, usage methods, and usage states not specifically described are the same as those in Embodiment 1.

Embodiment 3

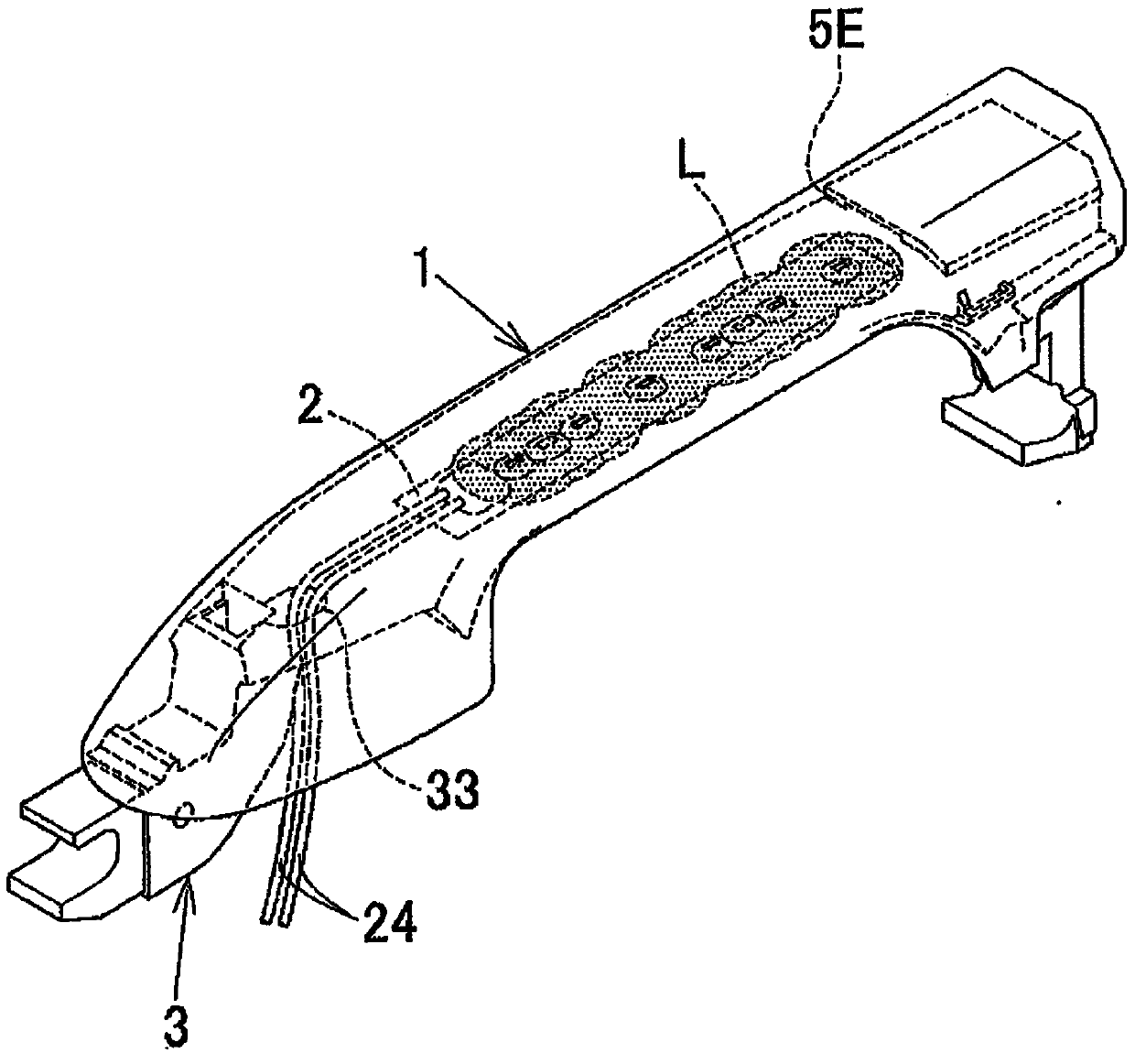

[0069] exist Figure 6 In the automotive functional part of the shown embodiment 3, the support frame 3 constitutes the respective automotive door handles of the rear door or the front door in a state covered with the molded cover 1, and is accommodated together with the surface light-emitting element 2 in the storage space. The detection means detects an opening and closing operation signal of a user's automobile door or a blinker operation signal. exist Figure 6 In the figure, the rear door and the front door each project a horizontally elongated rectangular rod-shaped transmissive light-emitting part L at the same height. Other configurations, usage methods, and usage states not specifically described are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com