Polyurethane-polyurea aqueous dispersion as well as preparation method and application thereof

A polyurethane and dispersion technology, used in textiles and papermaking, etc., can solve problems such as workability and solid content improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

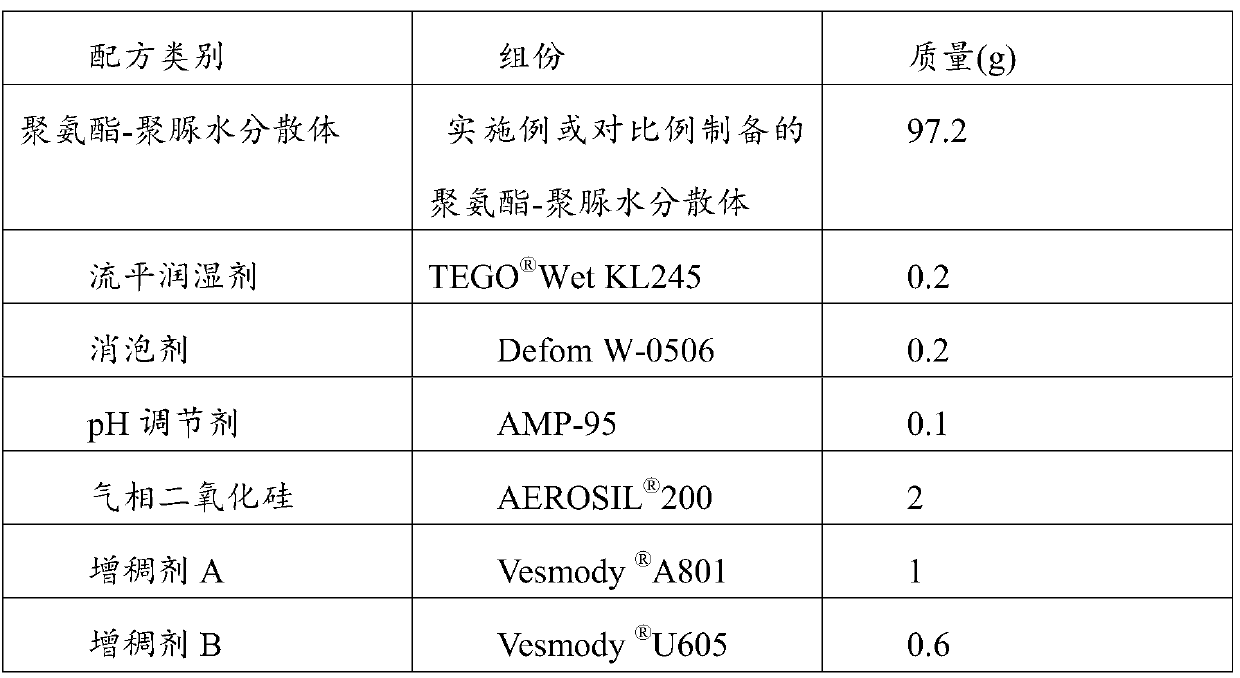

Method used

Image

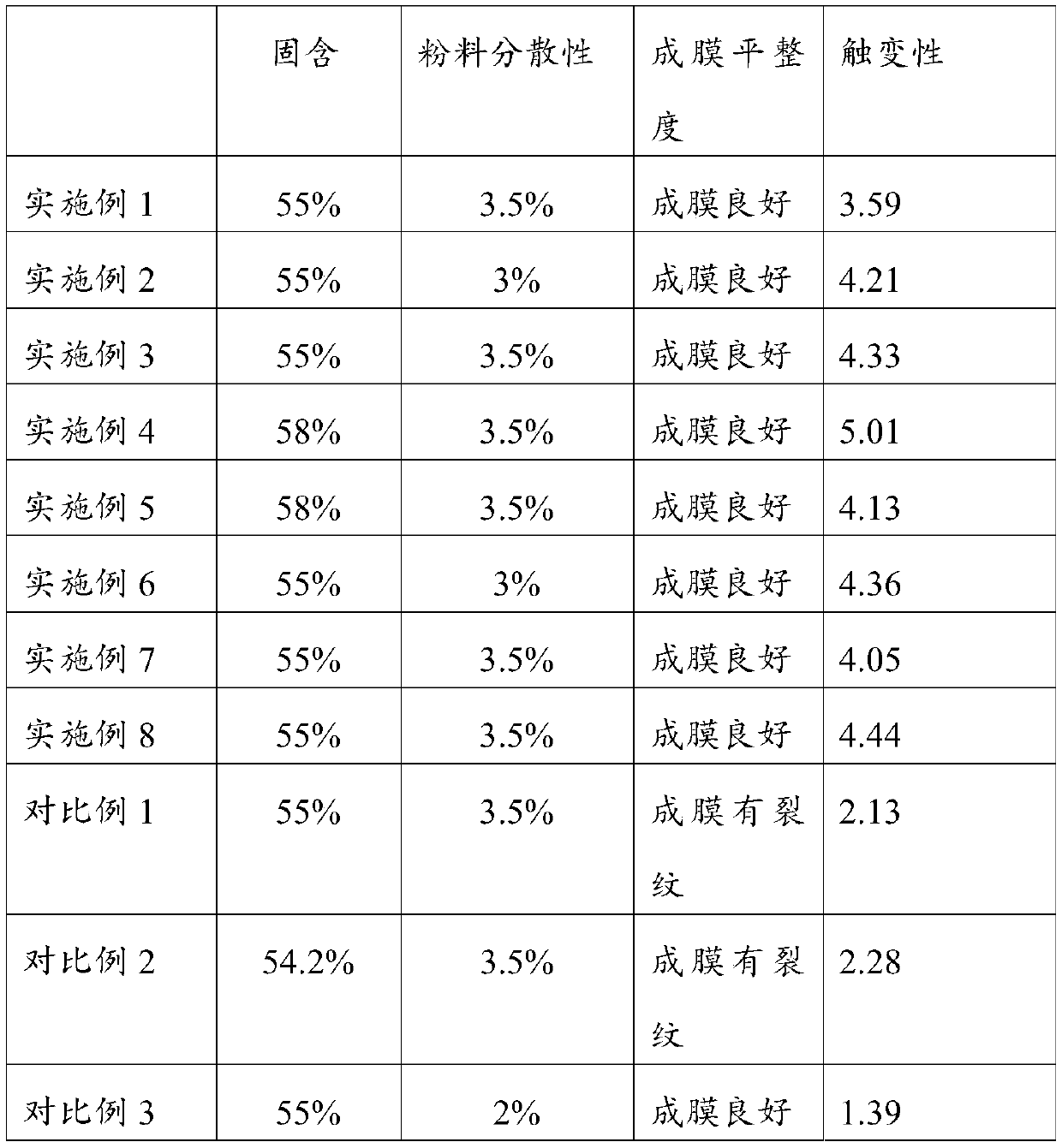

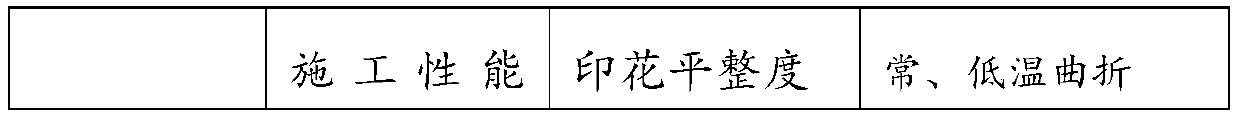

Examples

Embodiment 1

[0072] 147g of dehydration-treated polyol V (33.0wt%) and 220g of dehydration-treated polyol I (49.4wt%), 30g of HDI (6.7wt%), 30g of IPDI (6.7wt%), 3.0g of dehydration-treated MPEG -1200 (0.7wt%) and 50g of acetone were added to a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 60-90°C until the NCO reached 2.5%, and 550g of acetone was added to dilute the temperature and cooled to 40-90°C. 50°C, under rapid stirring, add 5 g concentration of 50% aqueous sodium N-(2-aminoethyl)-2-aminoethanesulfonate solution (N-(2-aminoethyl)-2- Sodium aminoethanesulfonate (0.6wt%) and 13g isophoronediamine (3.0wt%) were reacted for about 15min, and 400g deionized water was added under rapid stirring to disperse. After the acetone was separated by distillation, a solvent-free polyurethane-polyurea dispersion was obtained, and 2.7 g of triisopropanolamine (0.6 wt %) was added and stirred evenly. Finally, an aqueous polyurethane-po...

Embodiment 2

[0074] 170g of dehydrated polyol VI (41.2wt%) and 180g of dehydrated polyol II (43.6wt%), 47g of HDI (11.4wt%), 4.7g of IPDI (1.1wt%), 4.0g of dehydrated To process MPEG-1200 (1.0wt%), add 50g of acetone into a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, stir the mixture at 60-90°C until the NCO reaches 2.55%, add 500g of acetone to dilute and cool down to 40~50℃, under rapid stirring, add 4 g of 50% aqueous solution of N-(2-aminoethyl)-2-aminoethanesulfonate sodium solution (N-(2-aminoethyl)- Sodium 2-aminoethanesulfonate (0.5wt%) and 4.5g ethylenediamine (1.1wt%) were reacted for about 15min, and 379g deionized water was added under rapid stirring to disperse. After acetone was separated by distillation, a solvent-free polyurethane-polyurea dispersion was obtained, and 4.0 g of triisopropanolamine (1.0 wt %) was added and stirred evenly. Finally, an aqueous polyurethane-polyurea dispersion was obtained with a solids content of 55% by weigh...

Embodiment 3

[0076]300g of dehydration treated polyol I (83.0wt%), 40g HDI (11.2wt%), 8gIPDI (2.2wt%), 4.0g of dehydration treatment MPEG-1200 (1.1wt%), 45g acetone were added to the In a 1L four-necked round bottom flask with nitrogen inlet and outlet, stir the mixture at 60-90°C until the NCO reaches 2.9%, then add 600g of acetone to dilute and cool down to 40-50°C, add 6.0g diluted with 5 times water under rapid stirring Concentration is 50% N-(2-aminoethyl)-2-aminoethanesulfonate sodium aqueous solution (N-(2-aminoethyl)-2-aminoethanesulfonate sodium 0.8wt%) and 4.5g Ethylenediamine (1.3wt%) was reacted for about 15 minutes, and 350 g of deionized water was added under rapid stirring to disperse. After acetone was separated by distillation, a solvent-free polyurethane-polyurea dispersion was obtained, and 3.7 g of triisopropanolamine (1.0 wt %) was added and stirred evenly. Finally, an aqueous polyurethane-polyurea dispersion was obtained with a solids content of 55% by weight and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com