A kind of polyurethane-polyurea aqueous dispersion and its preparation method and application

A polyurethane and dispersion technology, applied in textiles and papermaking, etc., can solve the problems of workability and improvement of solid content, achieve good printing layout effect, improve construction performance, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

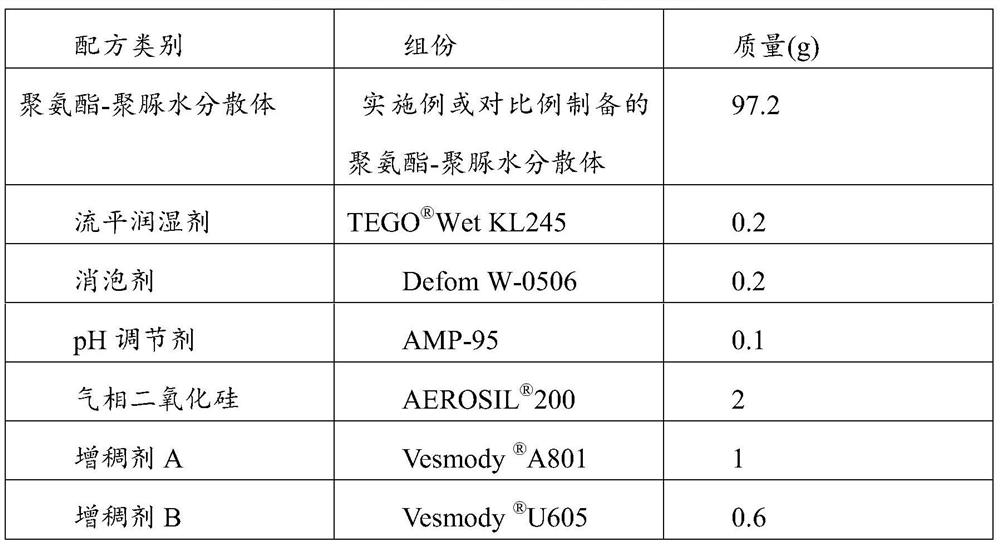

Method used

Image

Examples

Embodiment 1

[0072] 147g of dehydration-treated polyol V (33.0wt%) and 220g of dehydration-treated polyol I (49.4wt%), 30g of HDI (6.7wt%), 30g of IPDI (6.7wt%), 3.0g of dehydration-treated MPEG -1200 (0.7wt%) and 50g of acetone were added to a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 60-90°C until the NCO reached 2.5%, and 550g of acetone was added to dilute the temperature and cooled to 40-90°C. 50°C, under rapid stirring, add 5 g concentration of 50% aqueous sodium N-(2-aminoethyl)-2-aminoethanesulfonate solution (N-(2-aminoethyl)-2- Sodium aminoethanesulfonate (0.6wt%) and 13g isophoronediamine (3.0wt%) were reacted for about 15min, and 400g deionized water was added under rapid stirring to disperse. After the acetone was separated by distillation, a solvent-free polyurethane-polyurea dispersion was obtained, and 2.7 g of triisopropanolamine (0.6 wt %) was added and stirred evenly. Finally, an aqueous polyurethane-po...

Embodiment 2

[0074] 170g of dehydrated polyol VI (41.2wt%) and 180g of dehydrated polyol II (43.6wt%), 47g of HDI (11.4wt%), 4.7g of IPDI (1.1wt%), 4.0g of dehydrated To process MPEG-1200 (1.0wt%), add 50g of acetone into a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, stir the mixture at 60-90°C until the NCO reaches 2.55%, add 500g of acetone to dilute and cool down to 40~50℃, under rapid stirring, add 4 g of 50% aqueous solution of N-(2-aminoethyl)-2-aminoethanesulfonate sodium solution (N-(2-aminoethyl)- Sodium 2-aminoethanesulfonate (0.5wt%) and 4.5g ethylenediamine (1.1wt%) were reacted for about 15min, and 379g deionized water was added under rapid stirring to disperse. After acetone was separated by distillation, a solvent-free polyurethane-polyurea dispersion was obtained, and 4.0 g of triisopropanolamine (1.0 wt %) was added and stirred evenly. Finally, an aqueous polyurethane-polyurea dispersion was obtained with a solids content of 55% by weigh...

Embodiment 3

[0076]300g of dehydration treated polyol I (83.0wt%), 40g HDI (11.2wt%), 8gIPDI (2.2wt%), 4.0g of dehydration treatment MPEG-1200 (1.1wt%), 45g acetone were added to the In a 1L four-necked round bottom flask with nitrogen inlet and outlet, stir the mixture at 60-90°C until the NCO reaches 2.9%, then add 600g of acetone to dilute and cool down to 40-50°C, add 6.0g diluted with 5 times water under rapid stirring Concentration is 50% N-(2-aminoethyl)-2-aminoethanesulfonate sodium aqueous solution (N-(2-aminoethyl)-2-aminoethanesulfonate sodium 0.8wt%) and 4.5g Ethylenediamine (1.3wt%) was reacted for about 15 minutes, and 350 g of deionized water was added under rapid stirring to disperse. After acetone was separated by distillation, a solvent-free polyurethane-polyurea dispersion was obtained, and 3.7 g of triisopropanolamine (1.0 wt %) was added and stirred evenly. Finally, an aqueous polyurethane-polyurea dispersion was obtained with a solids content of 55% by weight and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com