Thermoplastic Resin Composition And Molded Article Formed Thereofrom

A technology of resin composition and plasticity, which is applied in the field of thermoplastic resin composition and its formed products, can solve the problems of reducing shear viscosity, restricting more, and improving the extensional viscosity of thermoplastic styrene resin, etc., to achieve shear Excellent shear viscosity and elongational viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described in detail. However, these embodiments are exemplary, and the present disclosure is not limited thereto.

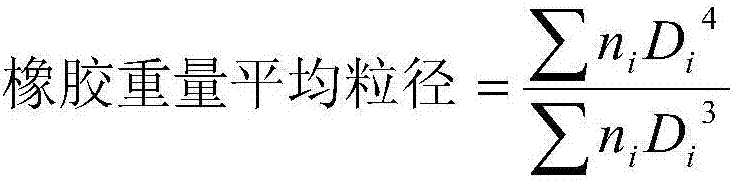

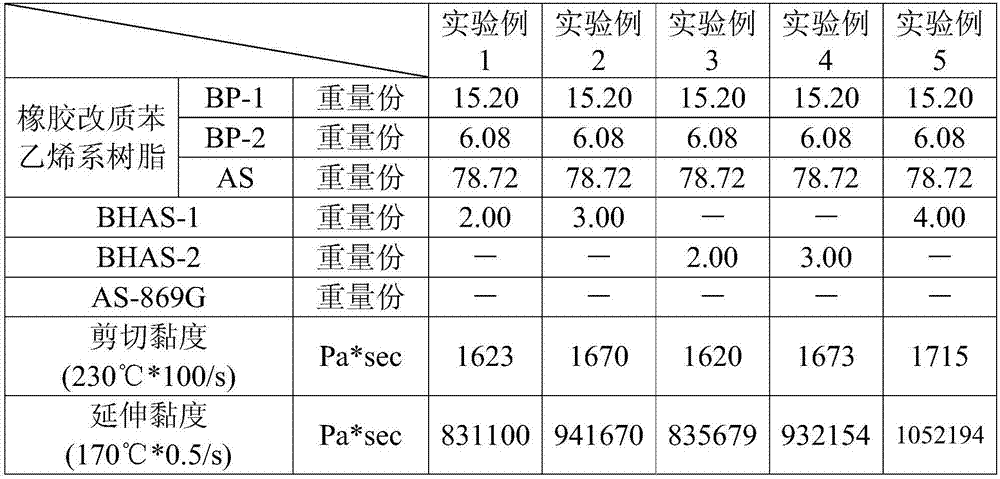

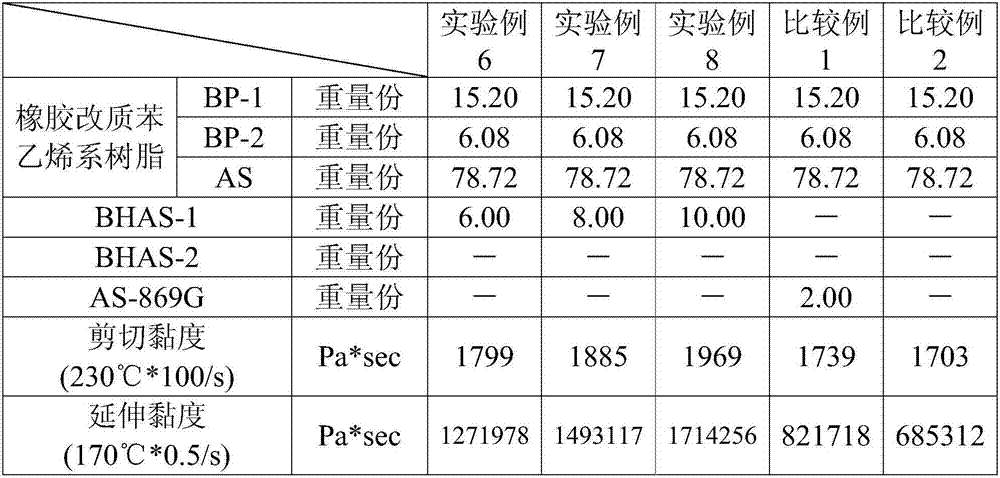

[0021] In one embodiment of the present invention, the thermoplastic resin composition comprises a rubber-modified styrene resin and a branched copolymer, the weight average molecular weight of the branched copolymer is 1 million to 7 million, and the branched copolymer has a weight average molecular weight of 1 million to 7 million. The compound contains a tetrathiol compound unit, a styrene-based monomer unit, and an acrylonitrile-based monomer unit. Here, the compound unit refers to a structural unit formed by a copolymerization reaction of a tetrathiol compound, and the monomer unit refers to a structural unit formed by a copolymerization reaction of a styrene-based monomer or an acrylonitrile-based monomer. And based on 100 parts by weight of the rubber-modified styrene resin, the content of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com