Intelligent photovoltaic panel cleaning system used for operation and maintenance of photovoltaic power station

A technology for photovoltaic power plants and cleaning systems, applied in photovoltaic power generation, cleaning methods using gas flow, photovoltaic modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

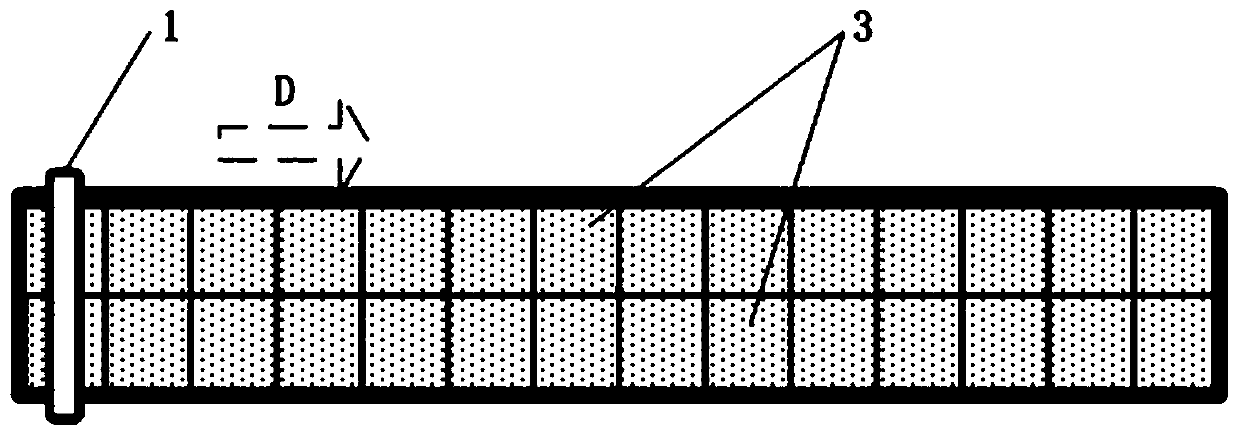

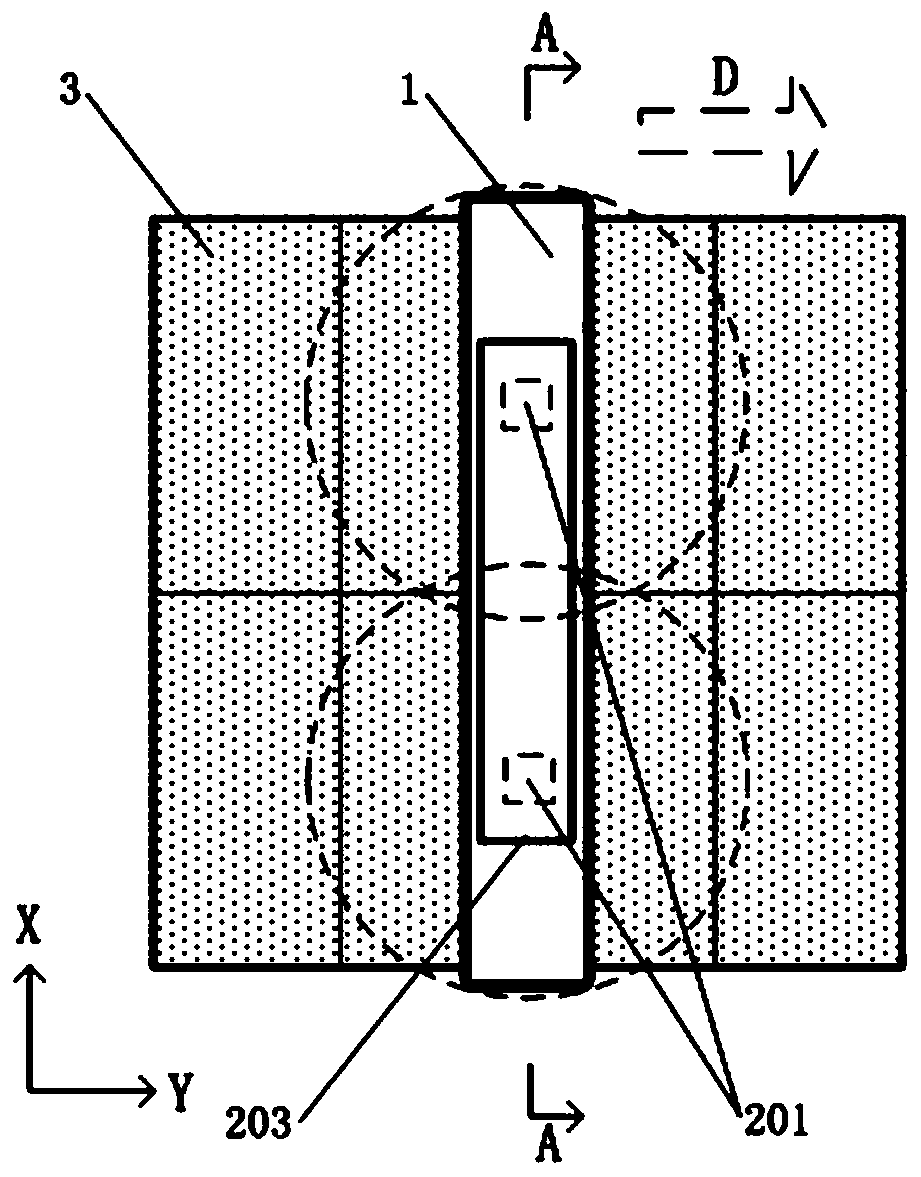

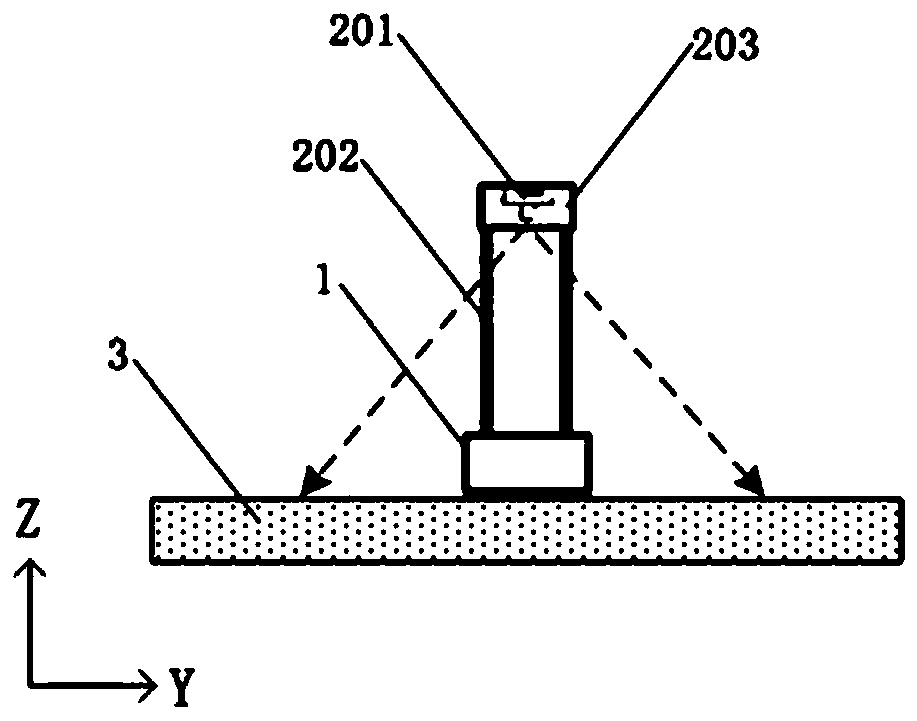

[0087] In this embodiment, the monitoring module adopts a direct shooting structure (replacing the indirect shooting structure), and the specific structure of the monitoring module is as follows:

[0088] The monitoring module also includes a lifting mechanism 202 and a movable cover 203; the camera device 201 is installed in the movable cover 203, the movable cover 203 is connected with the lifting mechanism 202, and the lifting mechanism 202 can shrink or stretch;

[0089]When the monitoring module is in the closed state, the movable cover 203 and the lifting mechanism 202 are shrunk and accommodated in the housing of the photovoltaic panel cleaning robot 1; when the monitoring module is in the open state, the lifting mechanism 202 stretches and drives the movable cover 203 to move upward To the top of the photovoltaic panel 3, the camera device 201 in the movable cover 203 collects the image of the photovoltaic panel 3 around the photovoltaic panel cleaning robot 1 downward;...

Embodiment 2

[0097] In this embodiment, the monitoring module adopts an indirect shooting structure, and the specific structure of the monitoring module is as follows:

[0098] The monitoring module also includes a lifting mechanism 202, a movable cover 203, and a reflector 204; the camera 201 is fixedly installed in the housing of the photovoltaic panel cleaning robot 1; the reflector 204 is installed in the movable cover 203, and the movable cover 203 Connected with the lifting mechanism 202, the lifting mechanism 202 can be contracted or extended;

[0099] When the monitoring module is in the closed state, the movable cover 203 and the lifting mechanism 202 are shrunk and accommodated in the housing of the photovoltaic panel cleaning robot 1; when the monitoring module is in the open state, the lifting mechanism 202 stretches and drives the movable cover 203 to move upward Going above the photovoltaic panel 3 , the camera device 201 captures the image of the photovoltaic panel 3 around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com