Offshore hydrogen production platform

An offshore, platform technology that can be used in final product manufacturing, sustainable manufacturing/processing, wind turbines that align with the wind direction, etc., and can solve the failure to achieve substantial progress in efficiency improvement and economics, lack of design experience, Engineering equipment and other issues have not yet been developed to achieve the effect of improving development utilization, optimizing space configuration, and improving consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0029] It should be noted that the orientation terms such as left, right, up, down, top, and bottom in this embodiment are only relative concepts, or refer to the normal use status of the product, and should not be regarded as having restrictive.

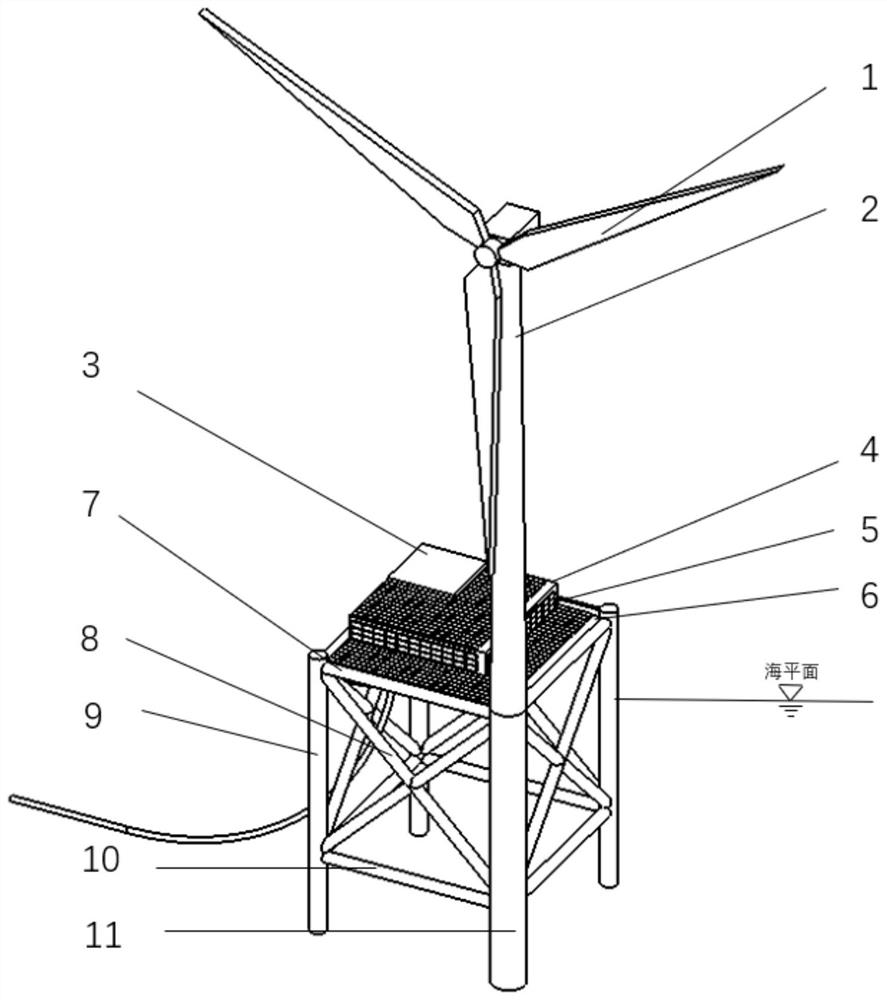

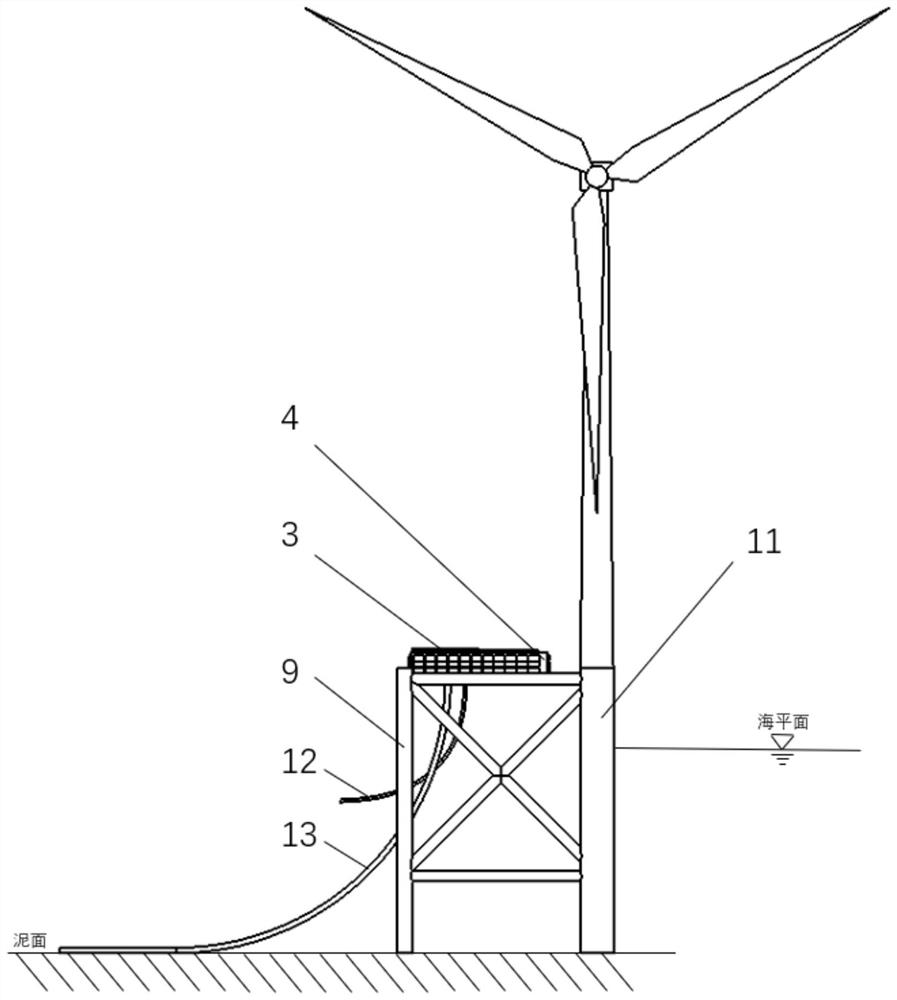

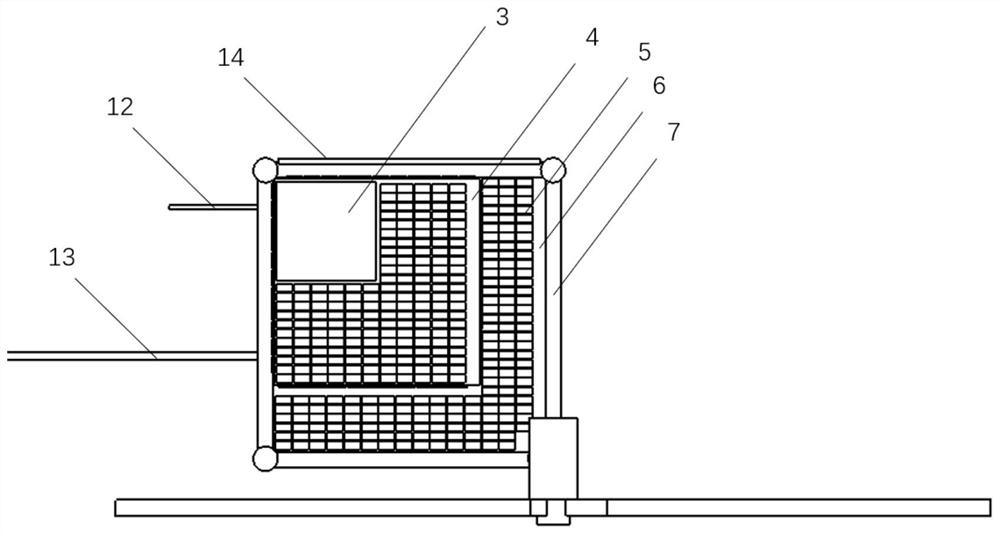

[0030] Such as Figure 1-5As shown, in some embodiments, an offshore hydrogen production platform (hereinafter, may be referred to as a platform for short) includes a horizontal axis wind turbine 1, a wind turbine tower 2, a wind turbine pile foundation 11, a jacket base, a deck 6, production and living Building 4, hydrogen production module 42, helipad 3 and several solar photovoltaic panels 5. The upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com