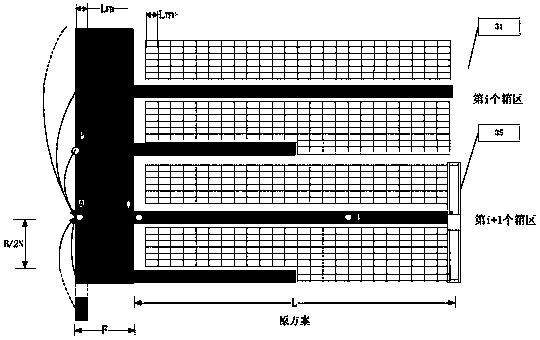

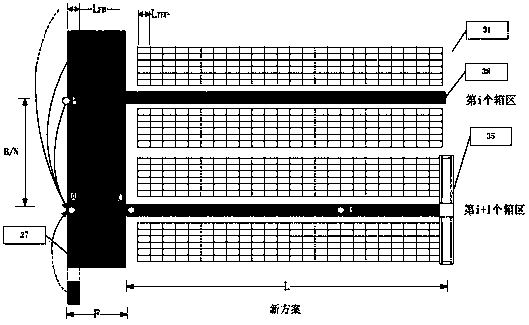

System and method for loading and unloading containers on multi-story frame type automated container yard

An automated terminal and multi-layer frame technology, which is applied to the multi-layer frame type container automated terminal storage yard system and its loading and unloading field, can solve the problem of poor flexibility of the operating system, low utilization rate of the storage yard, and insufficient number of vehicles to get off the ground. Work strength and other issues, to achieve the effect of reducing the moving distance and improving the efficiency of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

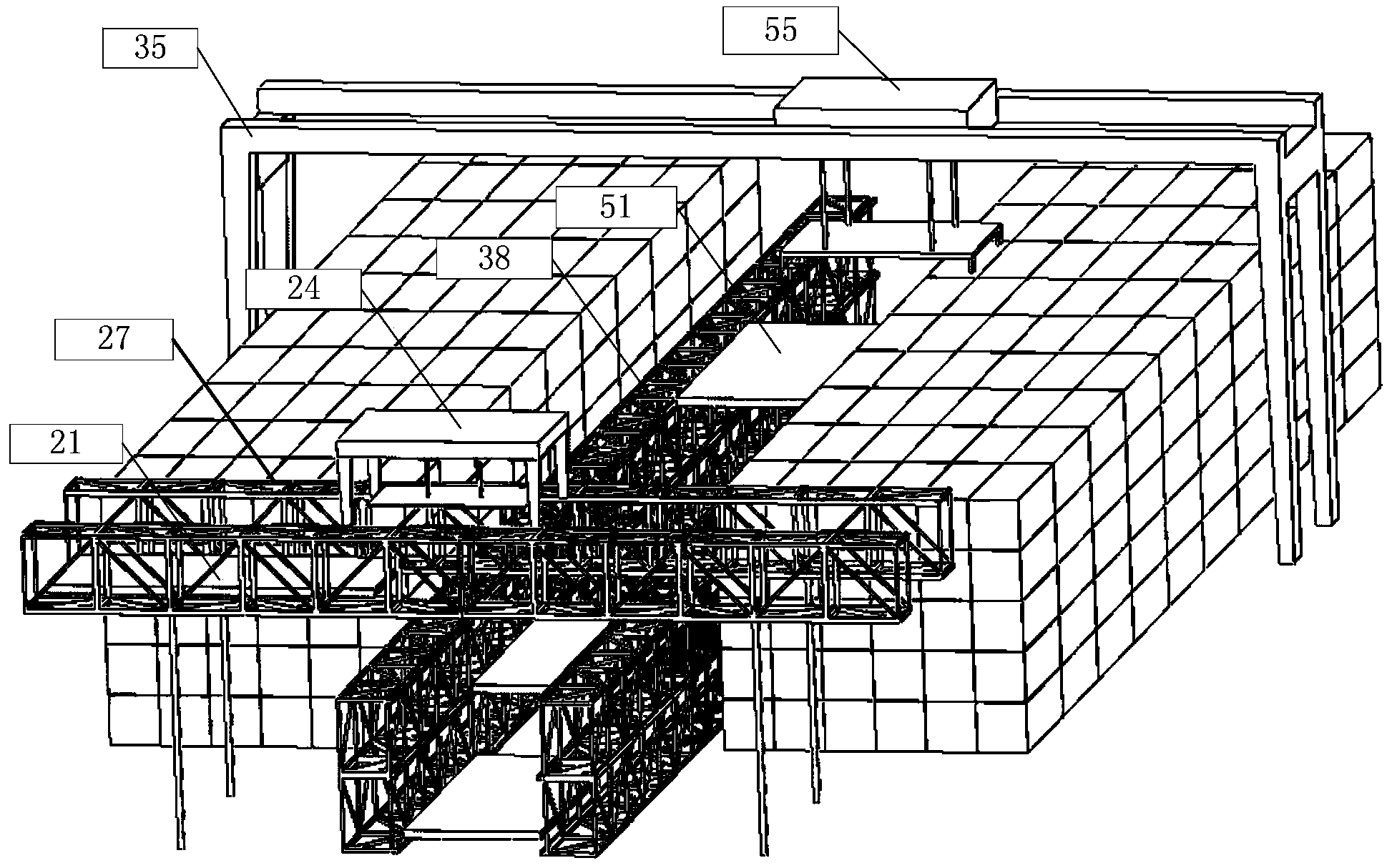

Embodiment Construction

[0058] The multi-layer frame track and the multi-layer low bridge track cooperate with each other to achieve the purpose of multi-line. A multi-storey frame bridge parallel to the shoreline is arranged at the front of the wharf. The lowest number of floors must be higher than the number of floors of the frame bridge in the box area, and a safety distance is left, and a low-bridge lifting trolley is arranged on the highest floor. The number of boxes is equal to the number of boxes, according to the needs of the job task, move to the designated job location. Except for the top floor, a low-bridge flat trolley is arranged on the other floors, and these trolleys can work at any position on the track without interfering with each other; in the storage yard, in the middle of each box area, and perpendicular to the shoreline A multi-layer box area track is arranged in the direction of the yard, and the track runs through the entire storage yard, from the front to the shore wall line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com