Auto-handling carriage of truck

A technology of automatic loading and unloading and compartments, which is applied to the arrangement of loading and unloading vehicles, vehicles used for freight, and the upper structure of trucks, etc. It can solve the problems of manpower consumption, difficulty in loading and unloading, and reduced comprehensive utilization rate, so as to achieve convenient loading and unloading. The effect of reducing labor intensity and improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

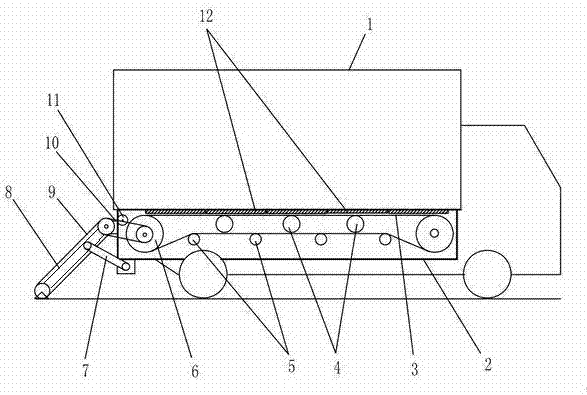

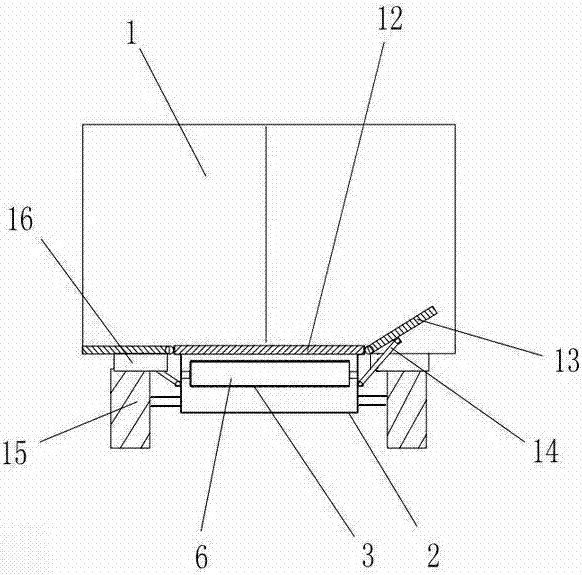

[0010] An automatic loading and unloading compartment of a freight car, comprising a compartment body 1, tires 15, and a girder 16, the compartment body 1 is fixed on the girder 16, and is characterized in that a bottom box 2 is installed between the bottom of the compartment body 1 and the left and right girders 16, and the bottom box 2 The upper end is open, and the bottom box cover plate 12 is placed at the open end of the bottom box 2; the left and right girders 16 at the two ends of the bottom box cover plate 12 are respectively connected to the movable bottom plate 13 through hinges, and the movable bottom plate 13 is composed of one or more rectangular plates. The lower part of 13 is connected with the base plate lifting hydraulic cylinder 14, and the movable base plate 13 rotates around the hinge; when the movable base plate 13 on both sides is horizontal, it is supported by the girder 16, and the bottom box cover plate 12 and the horizontal movable base plate 13 constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com