Particle packaging material storage logistics conveying system

A technology of warehousing logistics and conveying system, applied in the direction of conveyor objects, transportation and packaging, object stacking, etc., can solve the problems of inability to achieve fast loading and unloading, affecting the utilization of transit warehouses, taking up large space, etc., and achieving high efficiency and low maintenance. The effect of handling and stacking operations, reducing warehousing and logistics costs, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will Figure 1 to Figure 6 Specific embodiments of the present invention are described in detail.

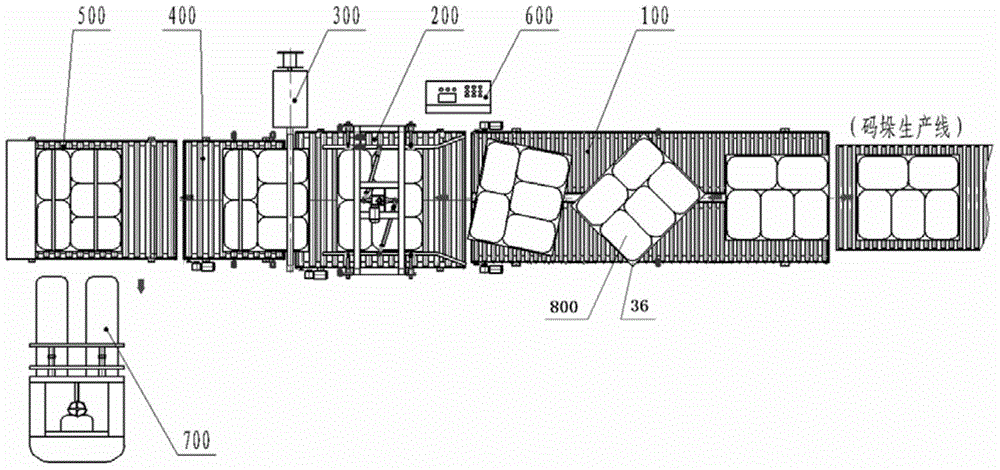

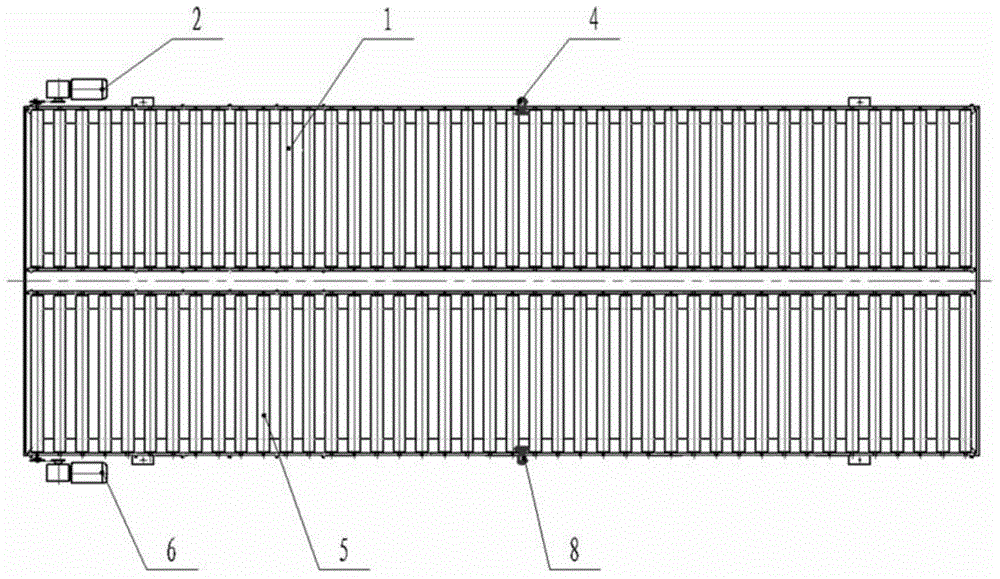

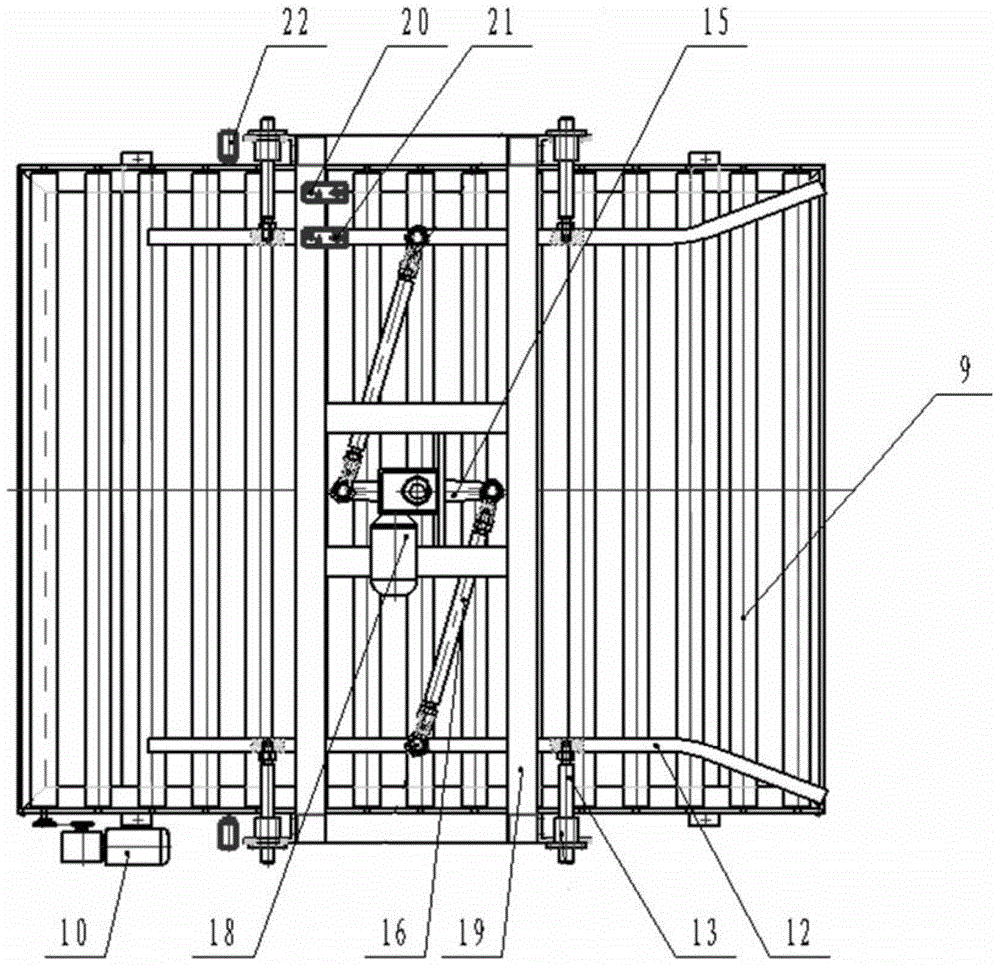

[0046] Such as figure 1As shown, a warehousing and logistics conveying system for powder packaging materials is connected to the palletizing production line, including a 90-degree steering conveyor 100, a guide leveling conveyor 200, a fully automatic belting machine 300, a transition conveyor 400, and a loading conveyor connected in sequence. The conveying platform 500 also includes a PLC control system 600 connected to the 90-degree turning conveyor 100, the guide leveling conveyor 200, the fully automatic belting machine 300, and the transition conveyor 400, and a push-pull forklift 700 and a push-pull forklift 700 The sliding carriage 36 used in conjunction with the 90-degree steering conveyor 100 is connected to the palletizing production line at one end, and is used to turn the sliding carriage 36 and the stacks placed on it 800 degrees from the palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com