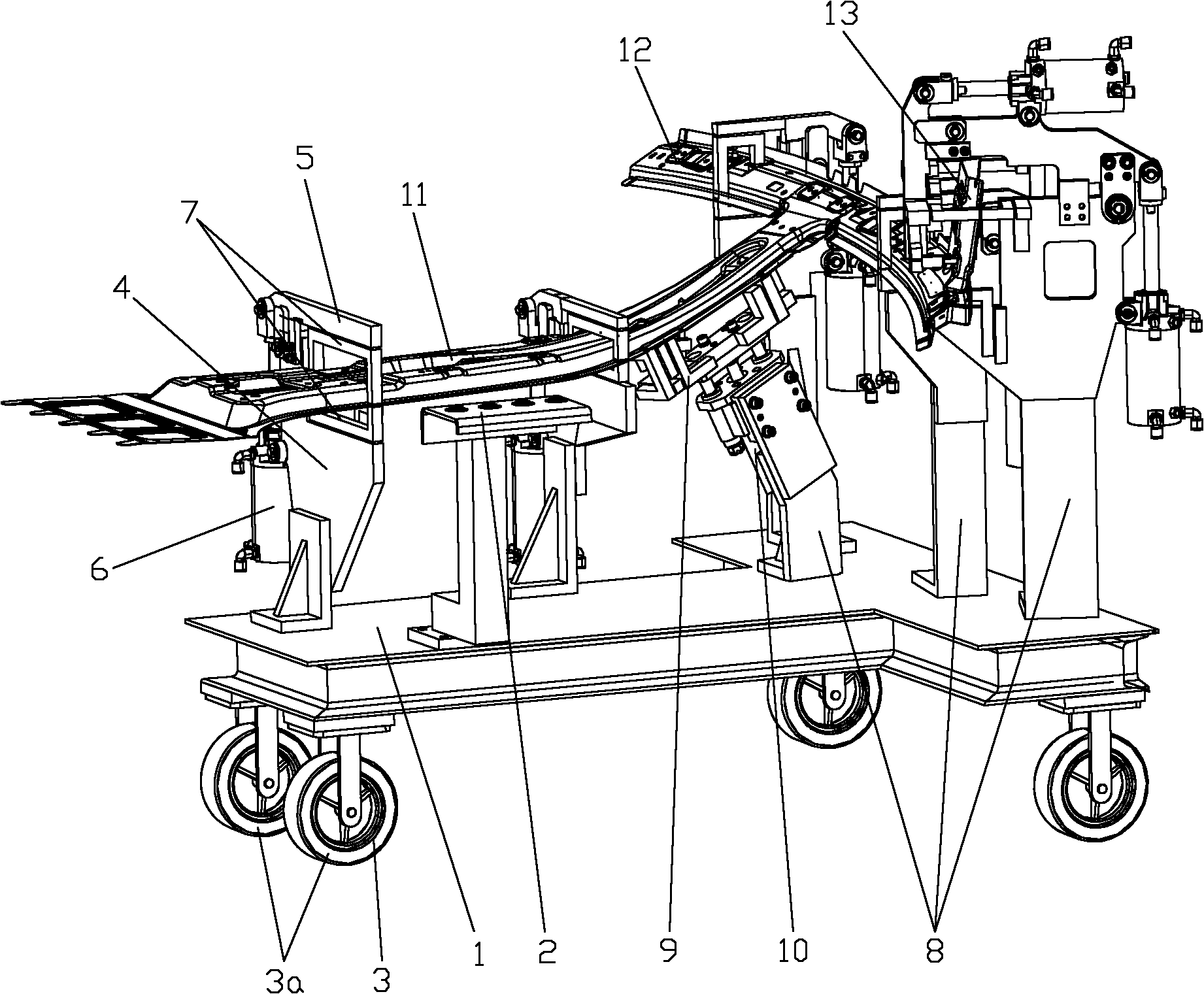

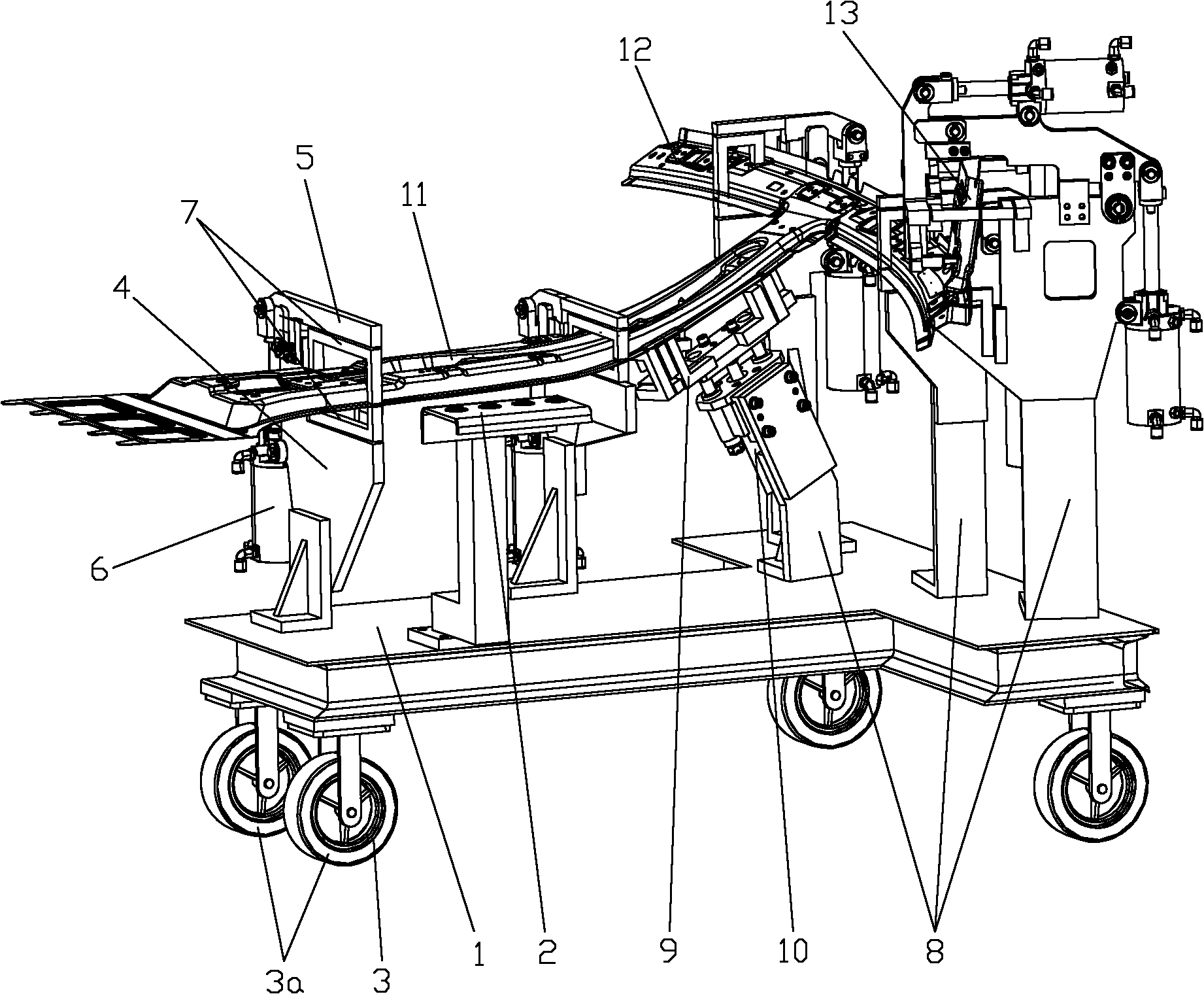

Fixture for sedan central pillar inner skin roof rail welding assembly

A technology of inner skin and columns, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low processing efficiency, heavy fixtures, and inconvenient movement, so as to achieve convenient movement, improve efficiency, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the welding assembly fixture for the upper side beam of the inner skin of the car center pillar in this embodiment is placed in the orientation shown in the figure, with the left end being the front end and the right end being the rear end. It consists of: including a base 1 and a clamping device fixedly installed on the base 1 and an operation panel 2; the top surface of the base 1 is a horizontal installation plane, and casters 3 are arranged at the bottom of the base 1; the clamping device includes a bracket 4 , the pressing frame 5 and the driving device 6, the bracket 4 is fixedly connected to the base 1, the pressing frame 5 is hinged on the bracket 4, and the driving device 6 is used to drive the bracket 4 and the pressing frame 5 to clamp and loosen , positioning pins are arranged on the bracket 4, when the workpiece is clamped, the corresponding eyelets on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com