Method and device for automatically measuring thicknesses of different mediums

An automatic measurement, medium thickness technology, applied in the direction of measurement device, electromagnetic measurement device, electromagnetic/magnetic thickness measurement, etc., to achieve the effect of simple placement, strong real-time performance, and less maintenance in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

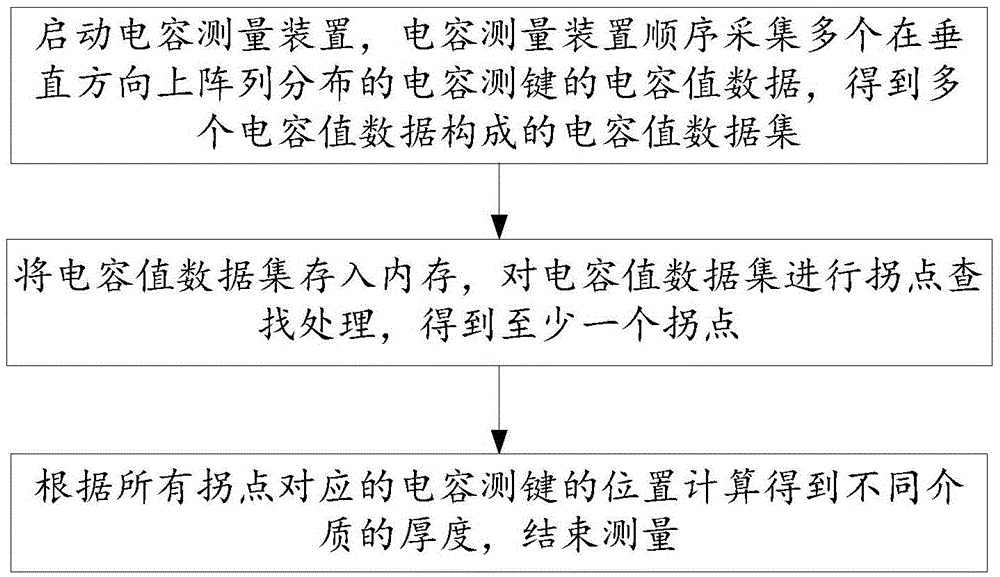

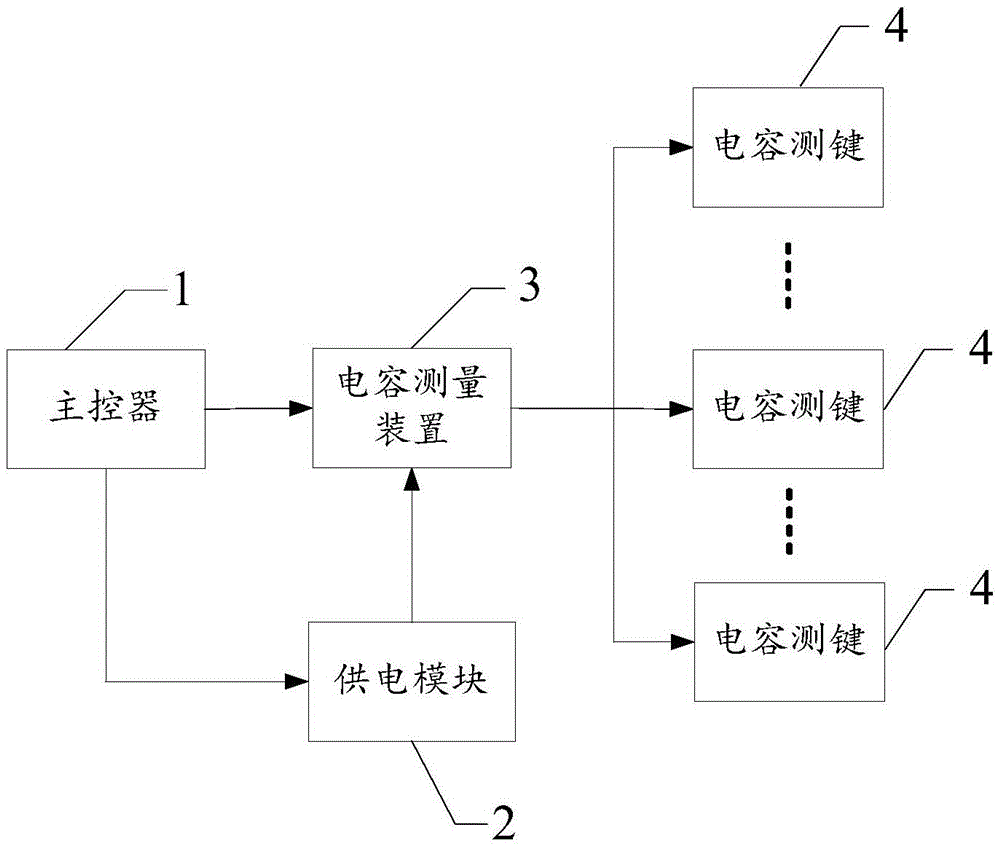

Method used

Image

Examples

Embodiment 2

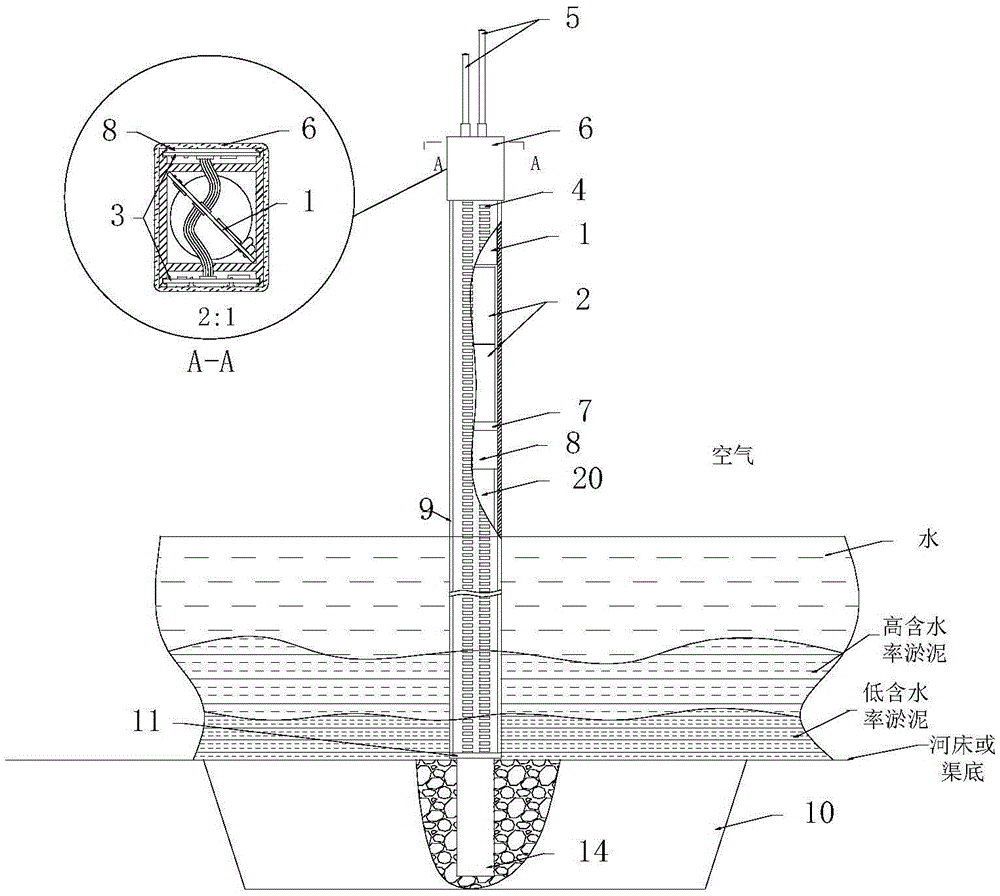

[0058] The measurement device described in Embodiment 2, on the basis of Embodiment 1, further includes a circuit board, all the capacitance measuring keys are evenly arrayed on the front side of the circuit board, and a capacitance measurement device is arranged on the reverse side of the circuit board.

Embodiment 3

[0059] The measurement device described in embodiment 3, on the basis of embodiment 1 or 2, also includes a metal casing and a fixed steel rod 14, the metal casing and the circuit board together form a closed columnar structure; the front of the circuit board faces the closed structure The power supply module is set in a closed structure; the reverse side of the circuit board and the metal casing together form a closed cavity; the power supply module is set in the closed cavity; the inside of the closed cavity near the top is provided with a main controller 1; the bottom of the closed cavity is connected with the fixed steel rod 14.

Embodiment 4

[0060] For the measuring device described in Embodiment 4, on the basis of Embodiment 3, the inside of the housing is filled with a sponge body 7 and a sealing resin 8, and the sponge body 7 is used to fix the position of the power supply module; the sealing resin 8 is used for To seal the inside of the housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com