Driving motor for electric car

A technology for driving motors and electric vehicles, which is applied to electric vehicles, motors, electric components, etc., can solve the problems of complex structure of power units, not suitable for application, and bulky, and achieves simple structure, good overall compactness, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

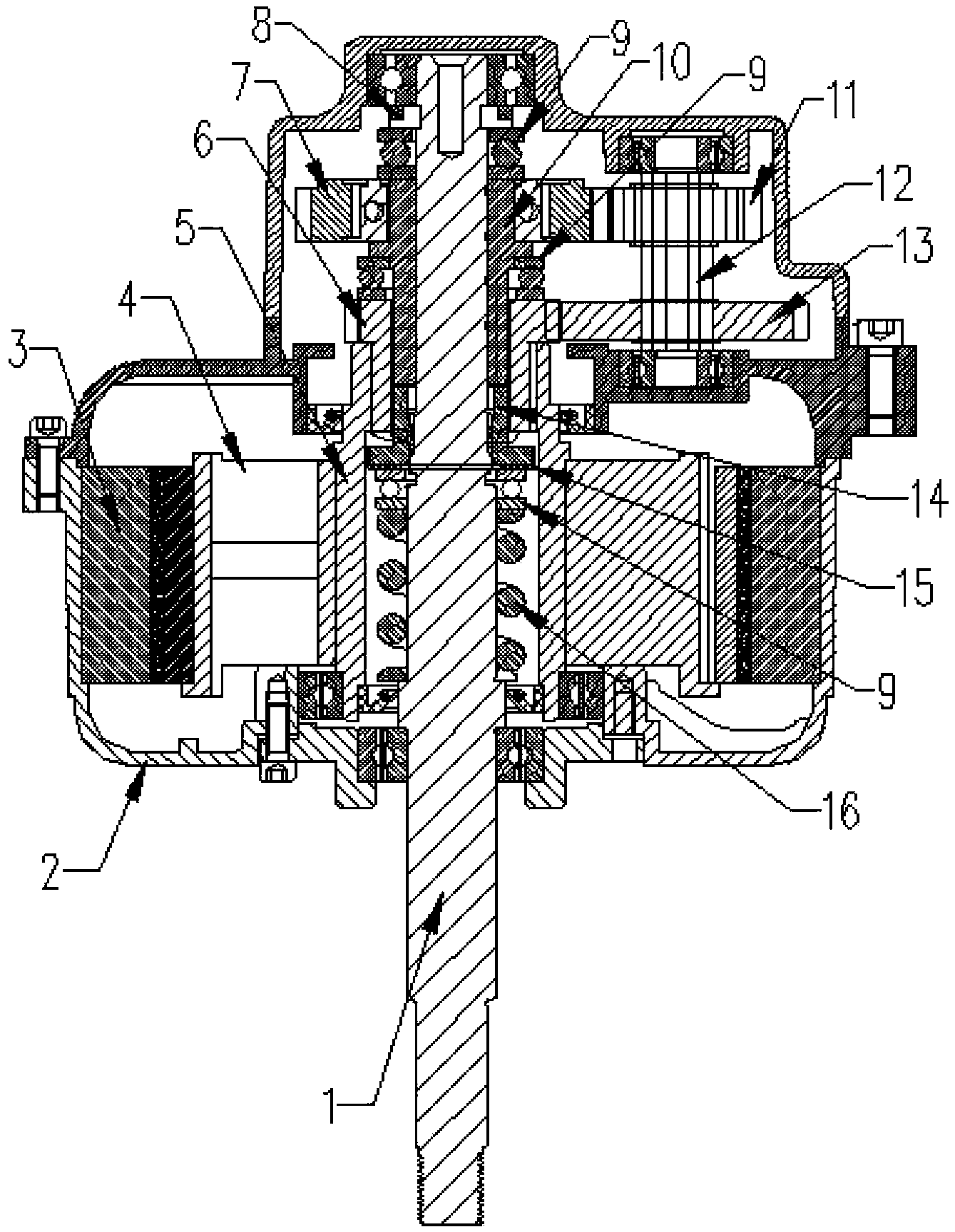

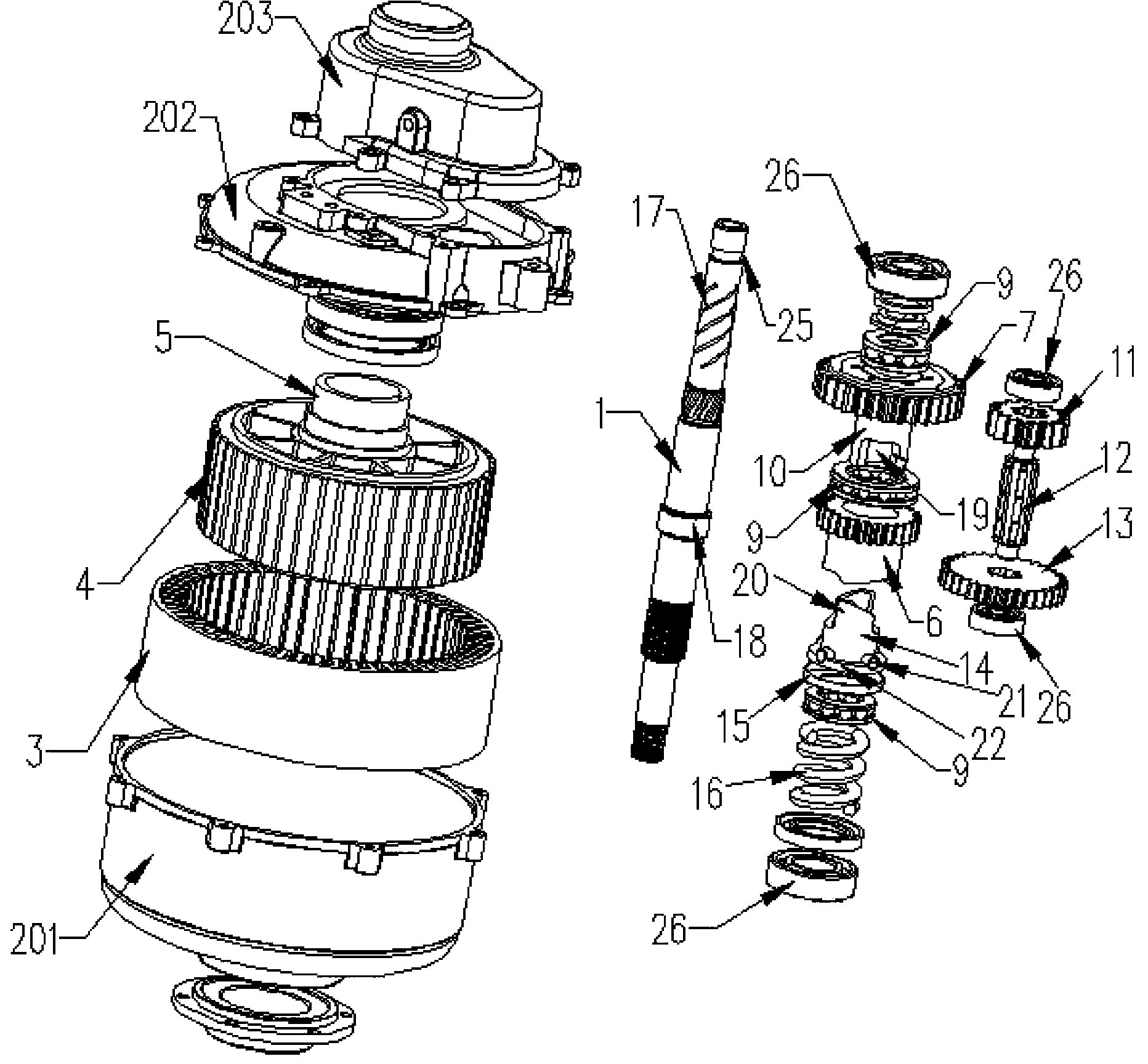

[0026] See figure 1 , 2 , the structure of the electric vehicle transmission motor of the present invention includes a housing 2, the housing 2 is a split structure, which is composed of a plurality of three single structures adapted to the assembly requirements of internal parts, and these three single structures are connected by bolts. And achieve fixation. The casing 2 is provided with a stator 3 and a rotor 4 arranged coaxially, and the main shaft 1 passes through the rotor 4 and can realize power transmission with the rotor 4 .

[0027] A spring 16 and a cylindrical clutch bracket 14 are sleeved on the outer periphery of the main shaft 1 in the housing 2. One end of the spring 16 presses against the boss 18 formed on the main shaft 1, and the other end of the spring 16 acts on the clutch bracket. 14 at one end. The clutch bracket 14 is circumferentially fixed to the main shaft 1 , and a spline structure cooperating with each other is provided between the clutch bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com