Hollow ball-screw gas-liquid binary cooling system

A ball screw and cooling system technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. The effect of positioning accuracy and stability, reducing the moment of inertia, and reducing the average temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

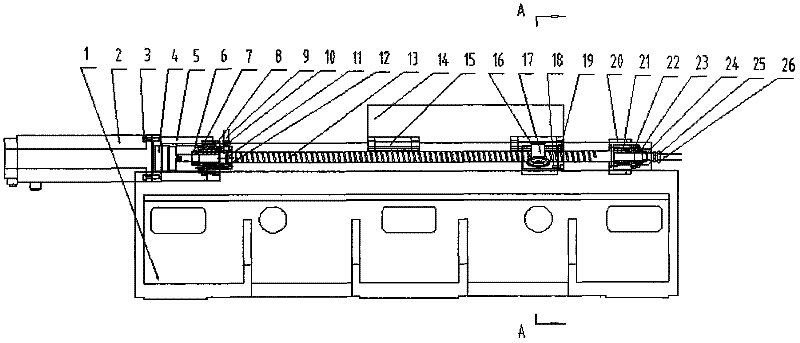

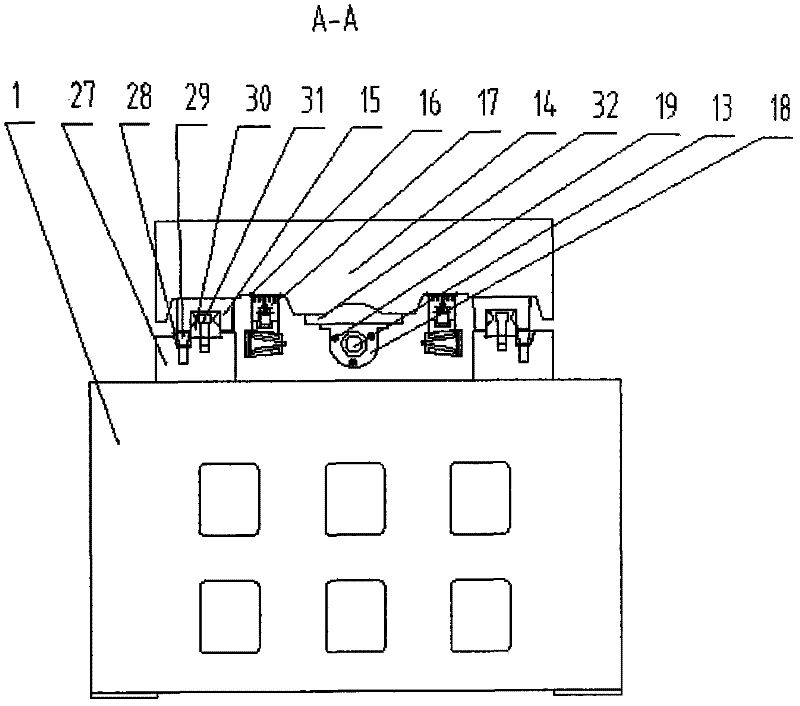

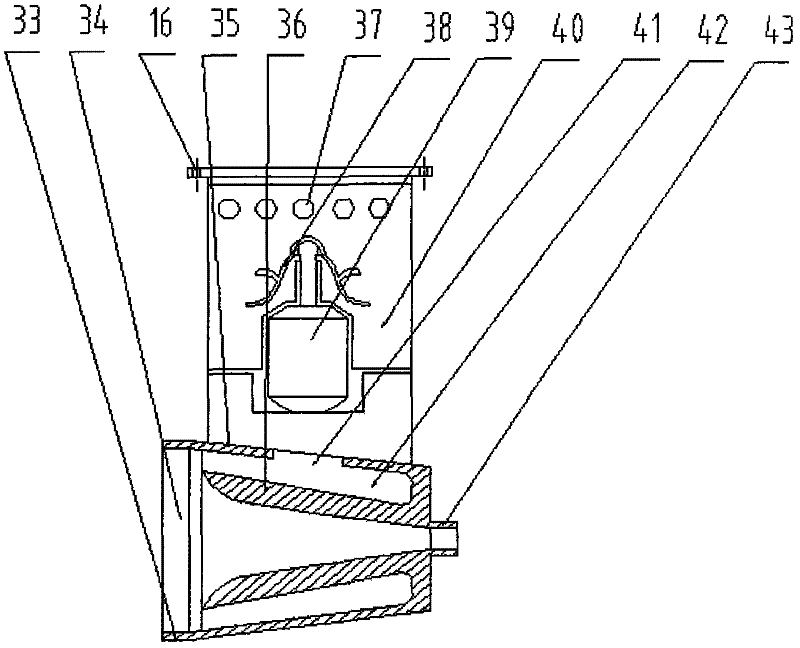

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a left end tile frame 5 is installed on the bed 1, and the servo motor 2 is fixed on the end face of the left end tile frame 5 through bolts 3, and is connected with the front end of the hollow ball screw 13 through a coupling 4. The front end of the hollow ball screw 13 is supported and installed on the left end tile frame 5 through the bearing group 8, and the round nut 6 is threadedly connected with the front end of the hollow ball screw 13, and is close to the seal 7 at the left end of the bearing group 8 for Axial positioning of the hollow ball screw 13. The ball screw oil hole 11 is located in the middle of the two sealing rings 12 and is connected with the oil inlet pipe 9 through the pipe joint 10 . The rear end of the hollow ball screw 13 is supported and installed on the right end tile frame 20 through the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com