Welding belt welding, transmission and holding device for solar cell series welding machine, and series welding machine

A solar cell and holding device technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of high cost, and achieve the effect of avoiding inaccurate transmission positioning and avoiding poor welding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structural features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings.

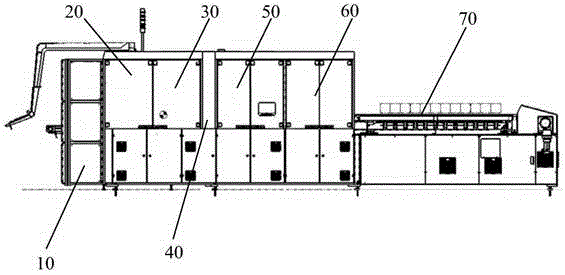

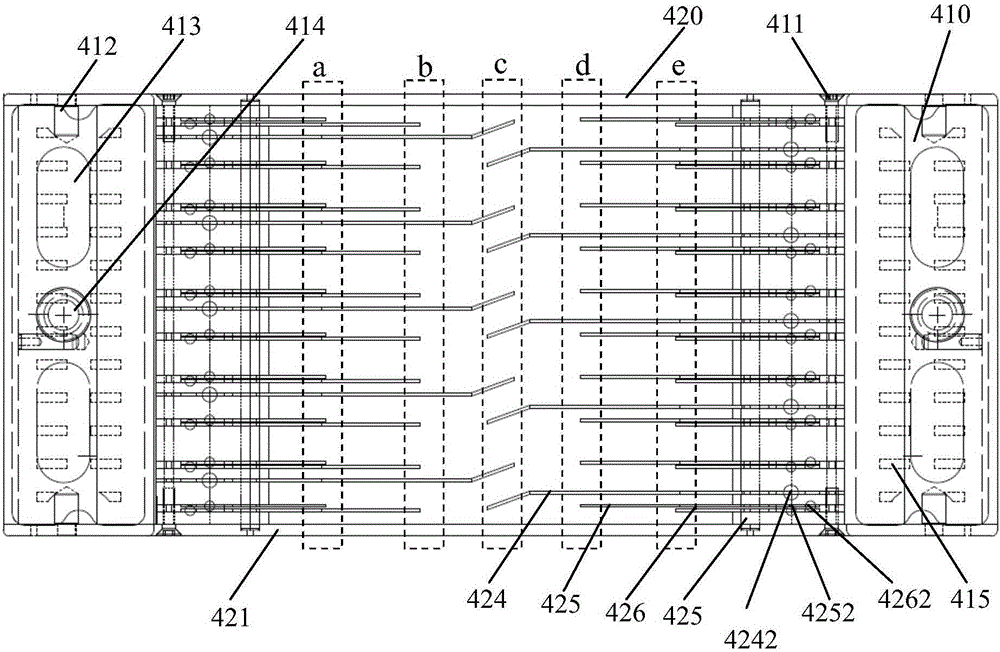

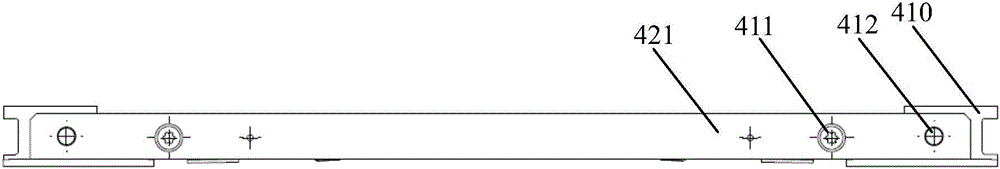

[0019] refer to figure 1 The structure diagram of the solar cell stringer shown in the figure, the stringer includes a ribbon supply unit 10, a solar cell sheet transfer unit 20, a ribbon and cell sheet alignment bonding unit 30, and a ribbon welding transmission holding unit Device 40, infrared welding unit 50, battery string transmission unit 60 after welding and battery string flip typesetting unit 70, during work, welding ribbon supply unit 10 will be required welding ribbon (5 welding ribbons in the present invention) Multiple motors drive the corresponding ribbon spools to rotate and transport them forward through the guide wheel set. At the same time, the battery sheet conveying unit 20 sends each battery sheet to the stringer, and the robot grabs the battery sheet to the steel belt conveyor belt. On the alignment and bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com