Potato seedling cutting and weeding machine

A weeder and potato technology, which is applied to harvesters, topping machines, land preparation machines, etc., can solve the problems of difficulty in removing weeds on potato seedlings and weeds with soil, so as to improve the efficiency of potato harvesting and ensure the production of commercial potatoes. The effect of quality and resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

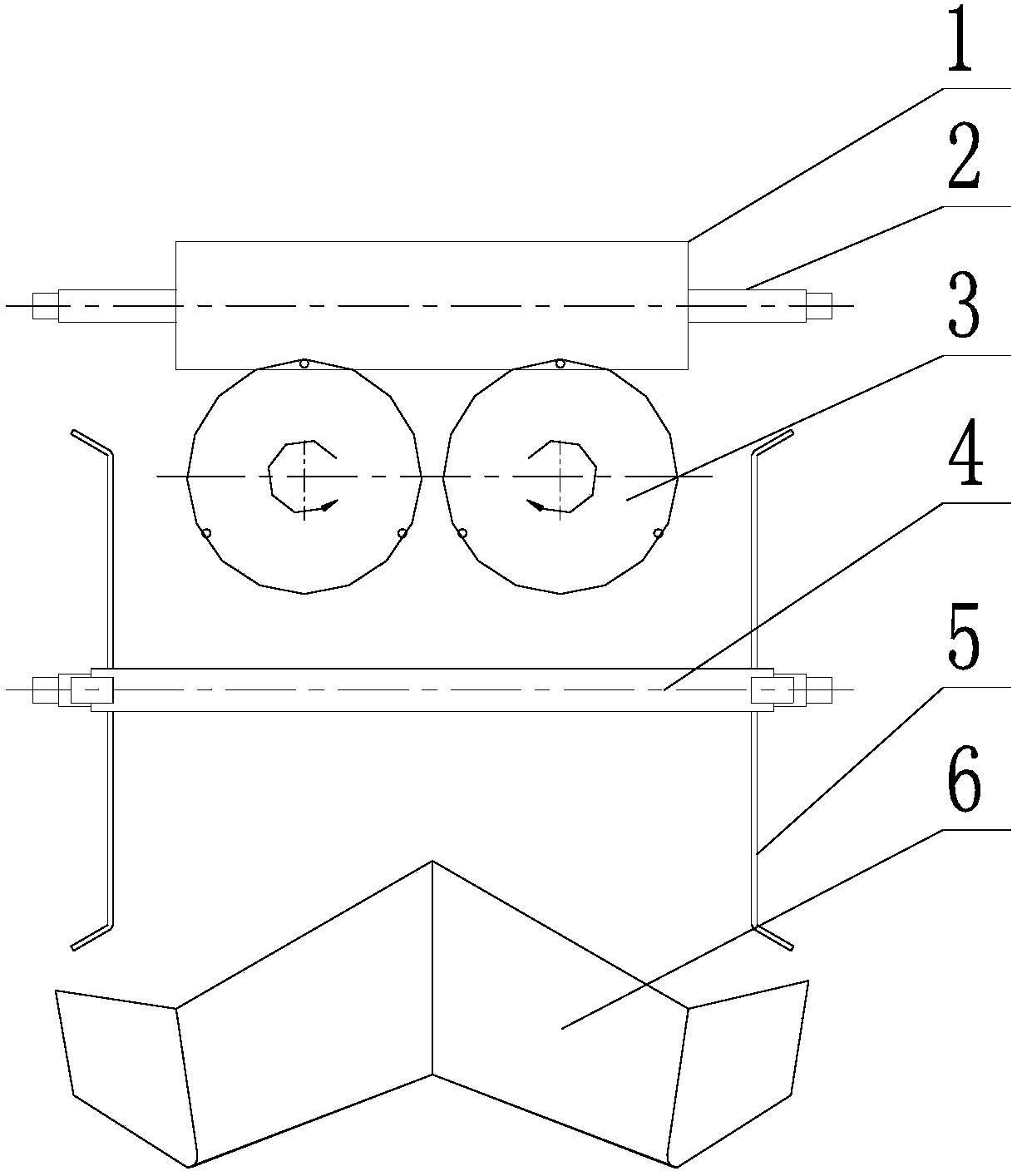

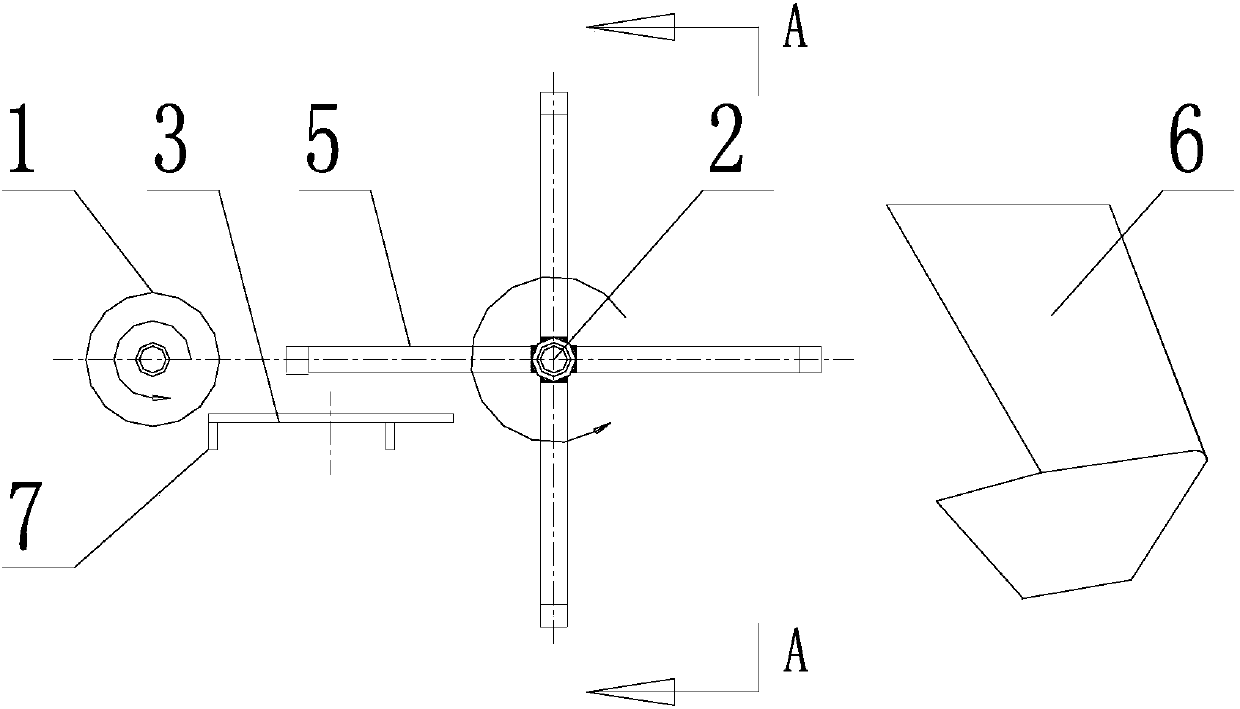

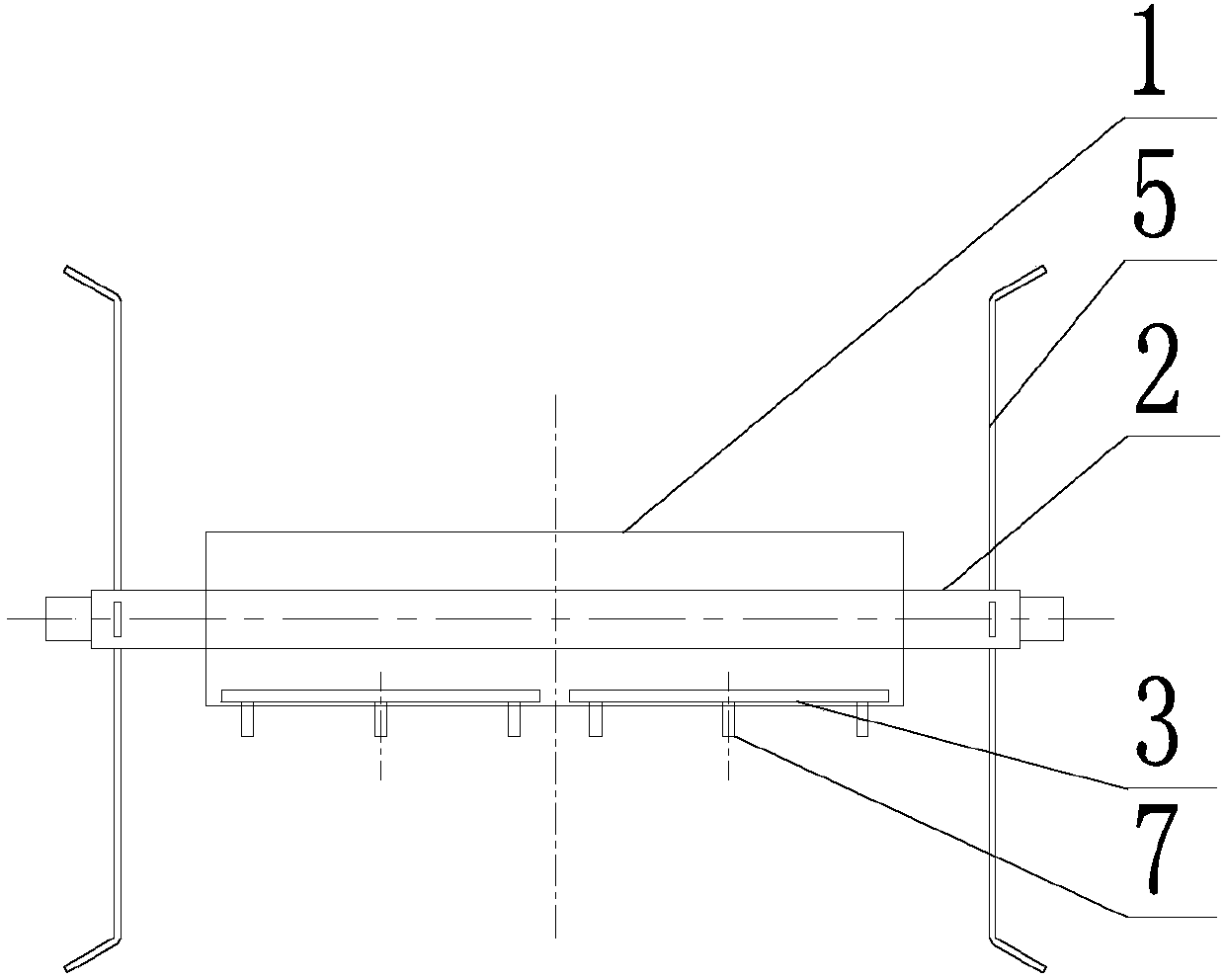

[0027] Such as figure 1 , figure 2 and image 3 As shown, the potato seedling weeding machine includes a positioning roller 1, a seedling pulling disc 3, a rotary tiller 5 and a "herringbone" shaped scraper 6, and the positioning roller 1 is set as a hollow cylinder structure, and the positioning roller The central axis of the roller 1 is provided with a pressing roller shaft 2, and two seedling pulling discs 3 are arranged at the position behind the bottom of the positioning pressing roller 1. 3. A plurality of cog teeth 7 are evenly inlaid along the outer edge of the circumference; a rotary tiller shaft 4 is arranged behind the disc 3 for pulling seedlings, and a rotary tiller 5 is arranged in a 360° ring on the outer walls of the two ends of the rotary tiller shaft 4 The rear of the rotary tiller shaft 4 is provided with a "herringbone" shaped scraper 6, and the center of the "herringbone" shaped scraper 6 is set against the midpoint of the rotary tiller shaft 4.

[002...

Embodiment 2

[0030] On the basis of Example 1, different from Example 1, such as figure 1 and figure 2 As shown, the potato seedling weeding machine includes a positioning pressure roller 1, a seedling pulling disc 3, a rotary tiller 5 and a "herringbone" shaped scraper 6, and the seedling pulling disc 3 is positioned along the axis of the positioning pressing roller 1 Set in parallel, and the diameters of the two turntables are the same, the sum of the diameters of the two seedling-pulling discs 3 is less than or equal to the length of the positioning roller 1, and the rotation directions of the two seedling-pulling discs 3 are opposite. The low-speed rotation mode in which the central axis rotates to the two outer sides. There is a gap between the seedling pulling disc 3 and the positioning pressure roller 1. The gap distance is set to be about 3 cm lower than the bottom of the positioning pressure roller 1. The blunt tooth Teeth 7 are set to a cylindrical rod structure, and the number...

Embodiment 3

[0032] On the basis of Example 1, different from Example 1, such as figure 1 and figure 2 As shown, the potato seedling weeding machine includes a positioning roller 1, a seedling pulling disc 3, a rotary tiller 5 and a "herringbone" shaped scraper 6, and the 5 rotary tillers are arranged in a 7-shaped curved knife structure, The 5 rotary tiller blades at the two ends of the rotary blade shaft 4 are installed respectively in the ridges on both sides of the double-row potato ridge, and the "herringbone" shaped scraper is set to be welded by the upper wing plate and the lower wing plate. The one-piece structure formed is arranged obliquely according to the slope of the double-row potato ridges, and its width is greater than the width of the rotary tiller shaft 4. The upper wing plate of the "herringbone" shaped scraper is set to be high at the front and low at the back and aligned with the horizontal plane. The parallelogram plate inclined at a certain angle, and the lower win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com