Patents

Literature

30results about How to "Real-time monitoring of speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

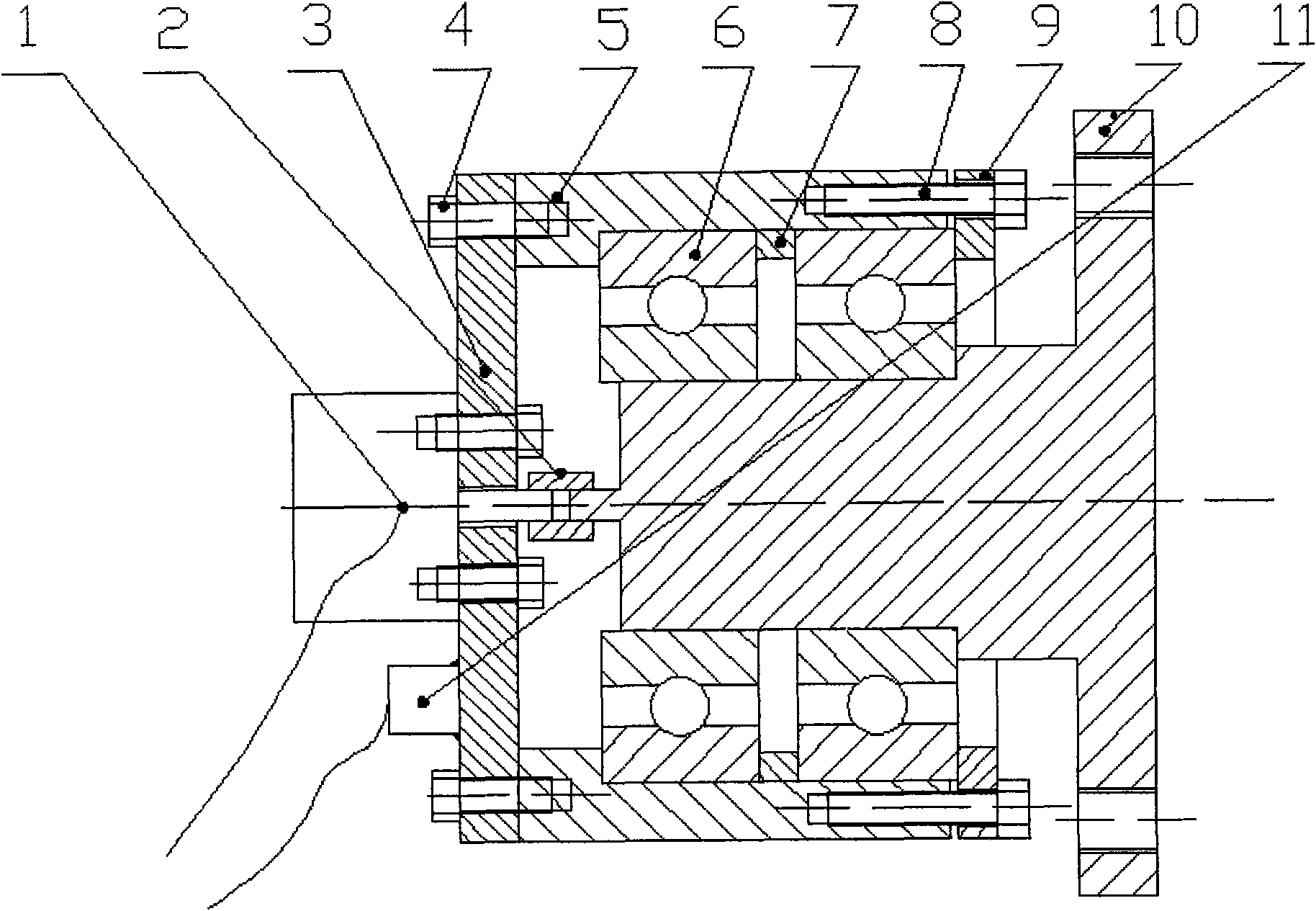

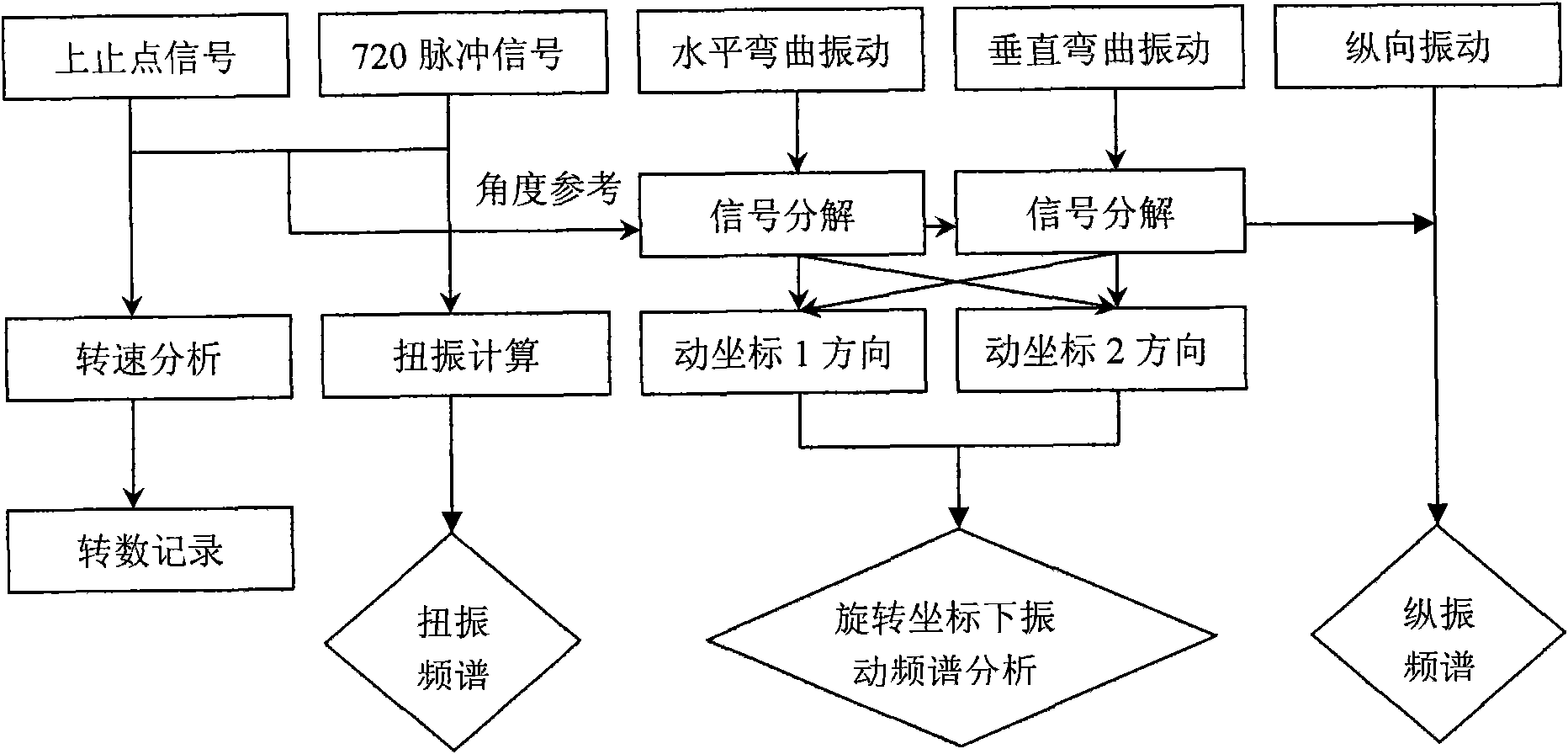

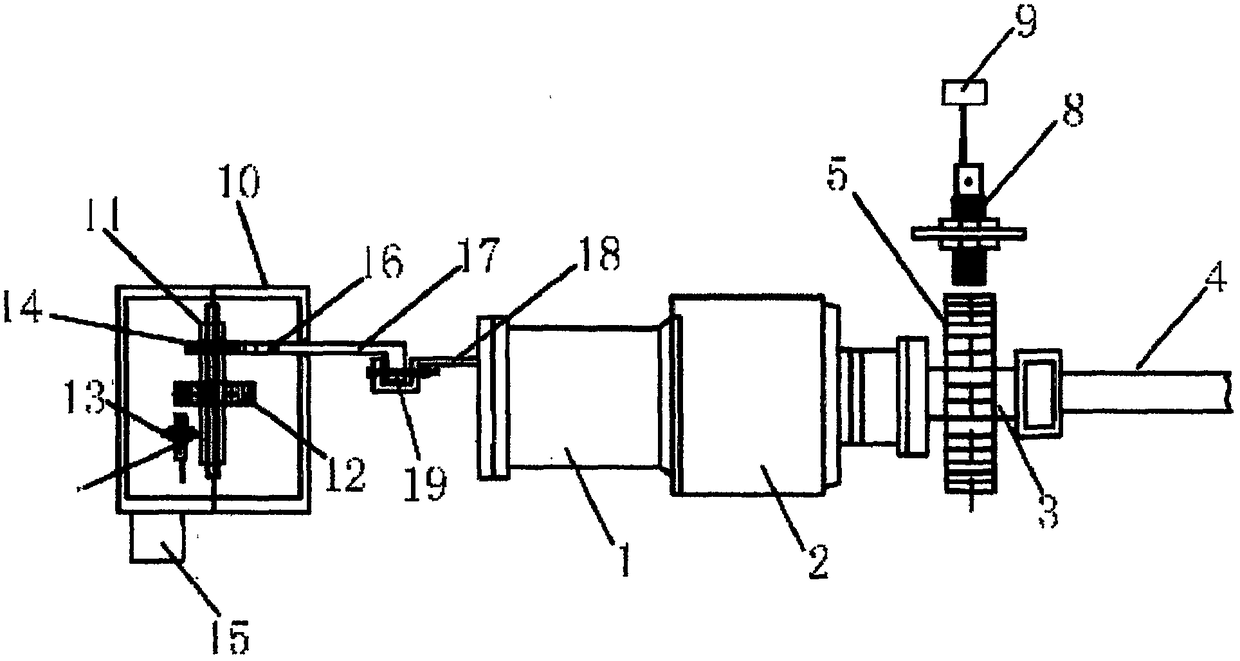

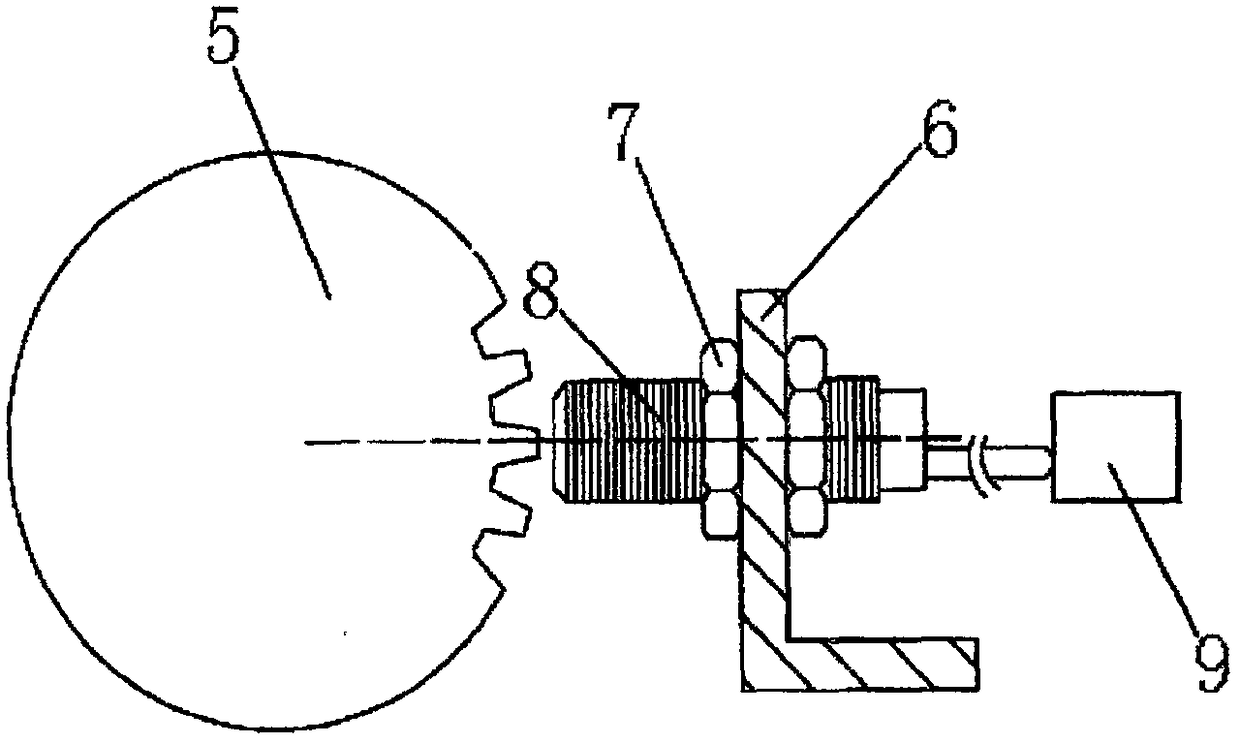

Measurement device capable of calibrating corner signal and three-dimensional vibration of crankshaft

InactiveCN101581623ARealize OKAchieving bending vibration decompositionInternal-combustion engine testingVibration testingMeasurement deviceBall bearing

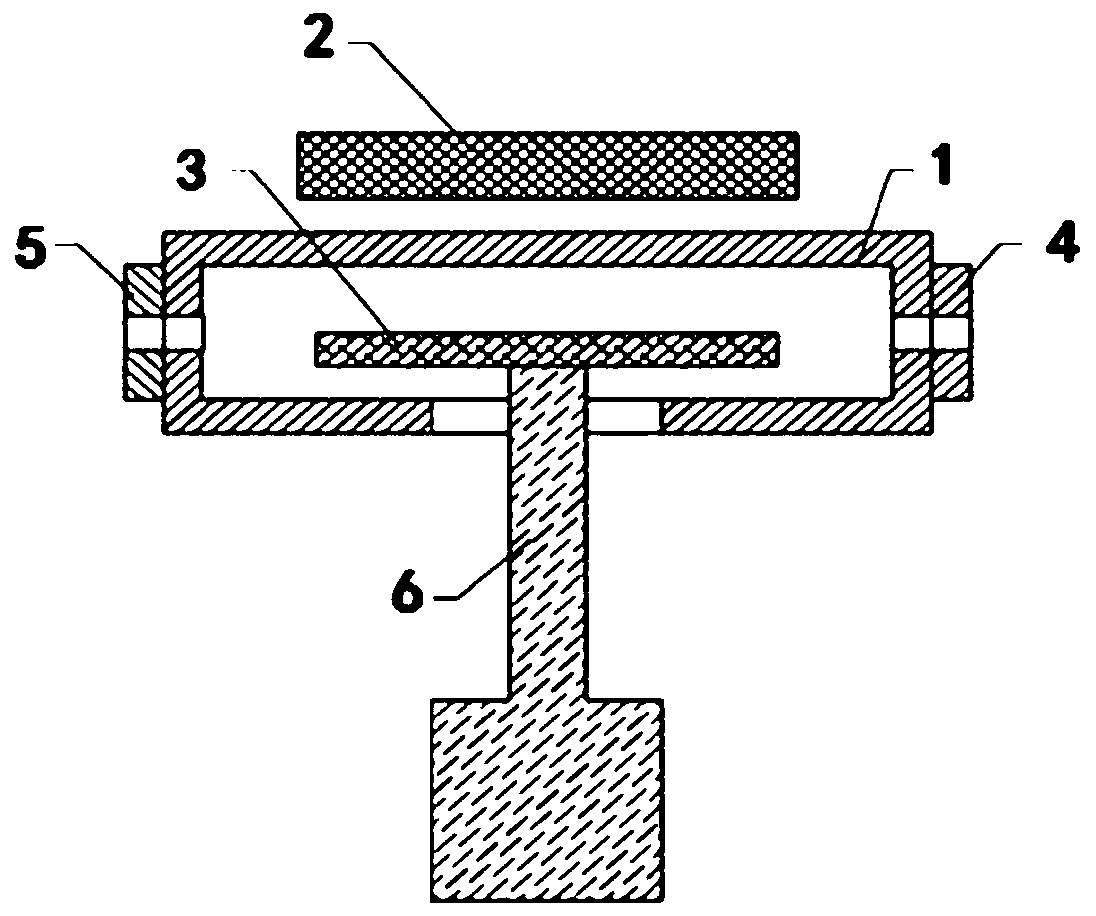

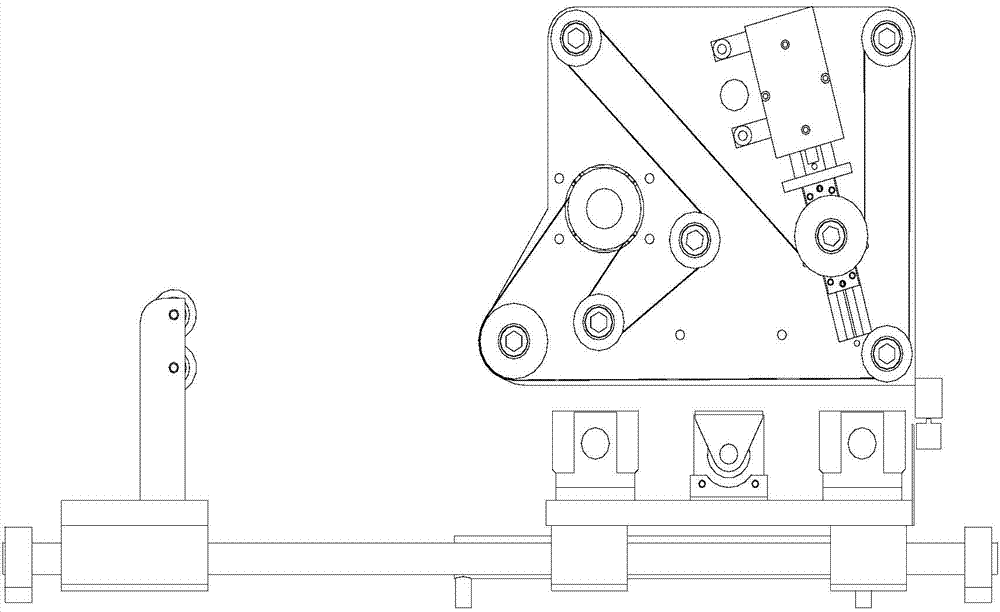

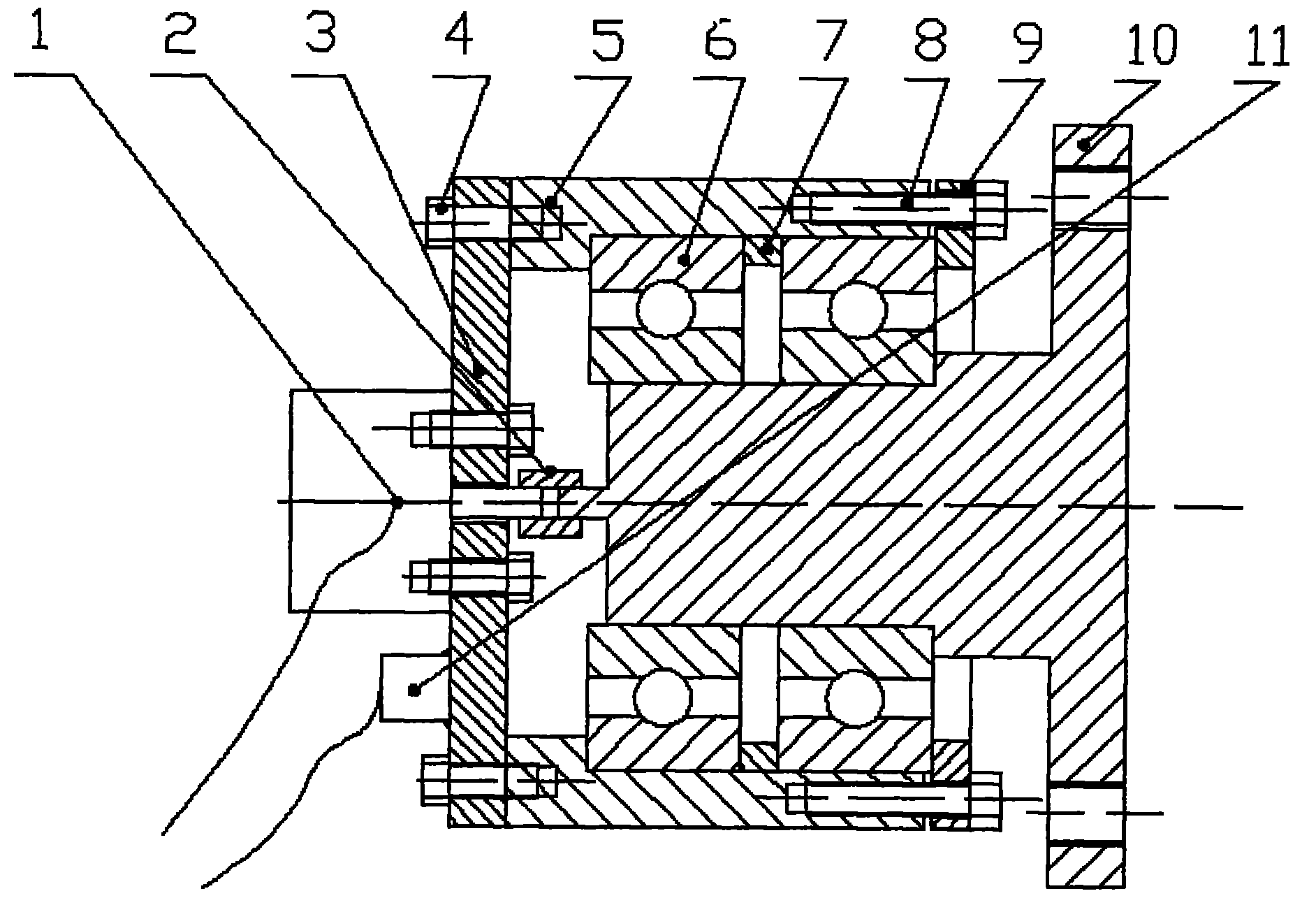

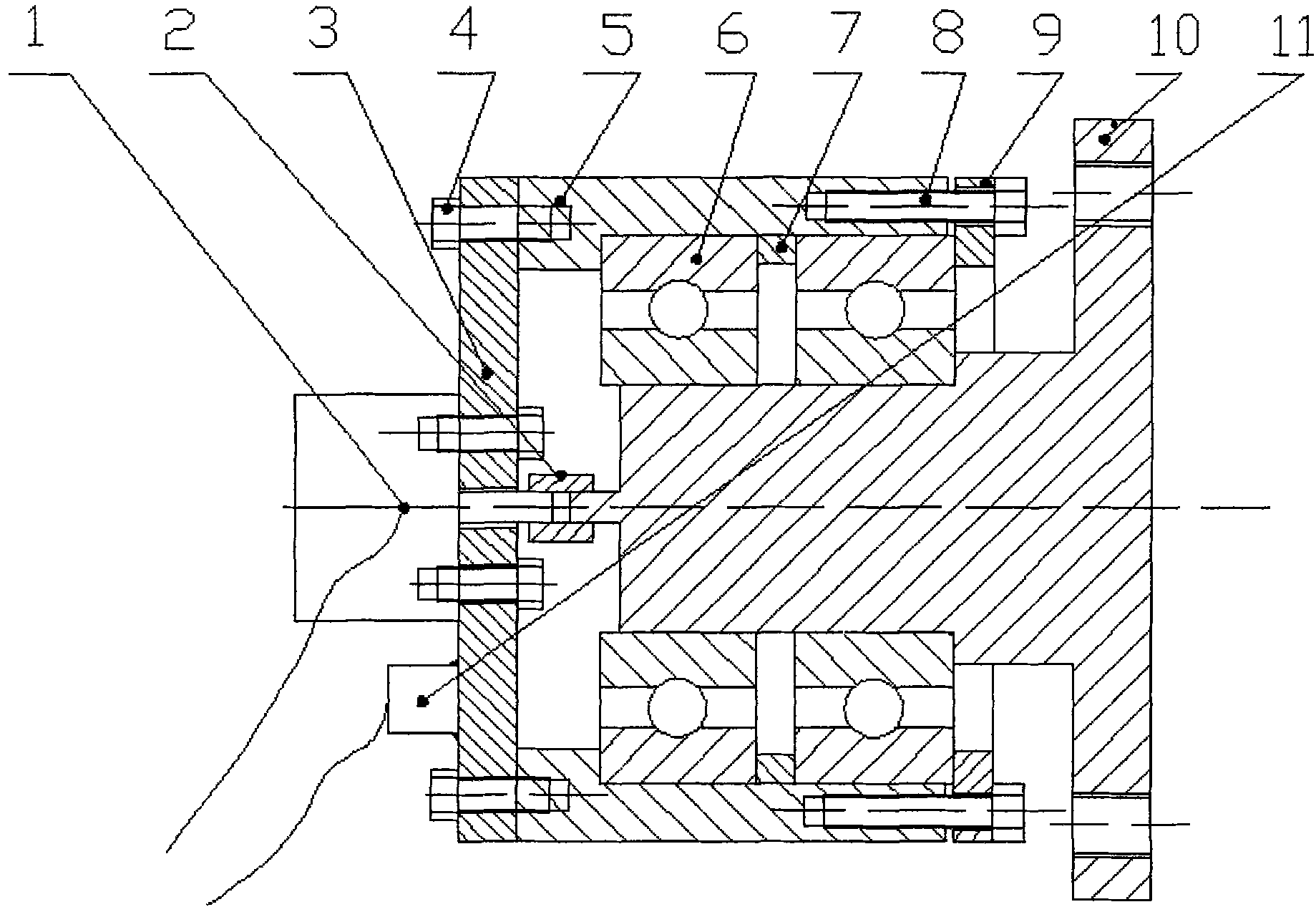

The invention discloses a crankshaft three-dimensional vibration measurement device capable of calibrating a crankshaft corner signal. A photoelectric encoder is fixed in the center hole of a stop block by a bolt, and the stop block is also fastened on the end face of a casing by the bolt. A pair of ball bearings is arranged between the casing and a transmission shaft, and the exterior ends of the ball bearings are fixed on the casing by a fastener bolt and a fastening check ring. The exterior end of the stop block is provided with a three-dimensional vibration sensor. The photoelectric encoder is connected with the transmission shaft by a connecting shaft to rotate synchronously and outputs two voltage signals which are respectively used for carrying out the torsional vibration analysis and the top dead centre calibration of a crankshaft. In the invention, bending vibration under different corners of the crankshaft can be decomposed, and synthesis is carried out on the rotating coordinate system of the crankshaft at a position corresponding to the corner of the crankshaft, so that the measurement of the rotating coordinate system of the crankshaft can be realized, bending vibration consistent to the rotating coordinates of the crankshaft is obtained by software calculation, and real-time monitoring can be carried out on an engine in terms of the revolution speed and the revolution number.

Owner:TIANJIN UNIV

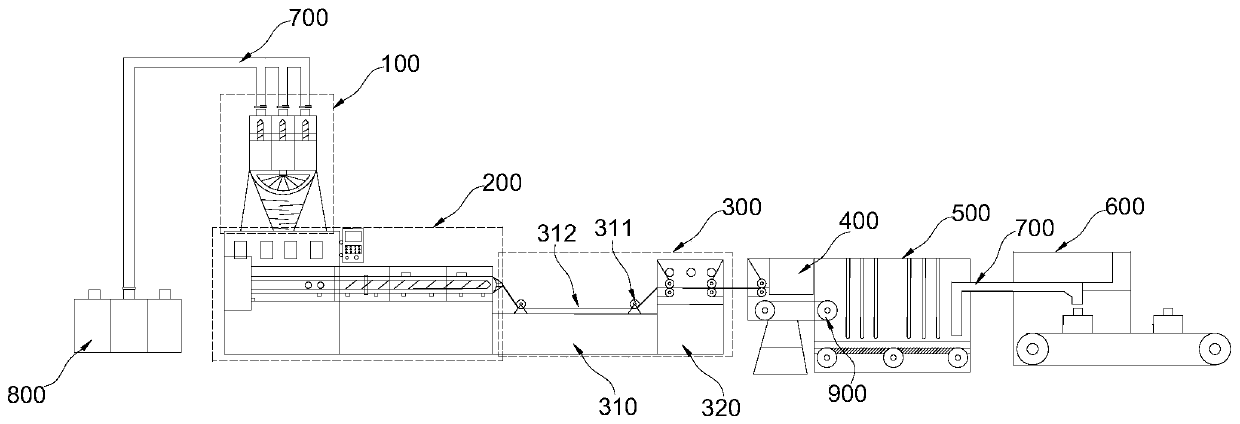

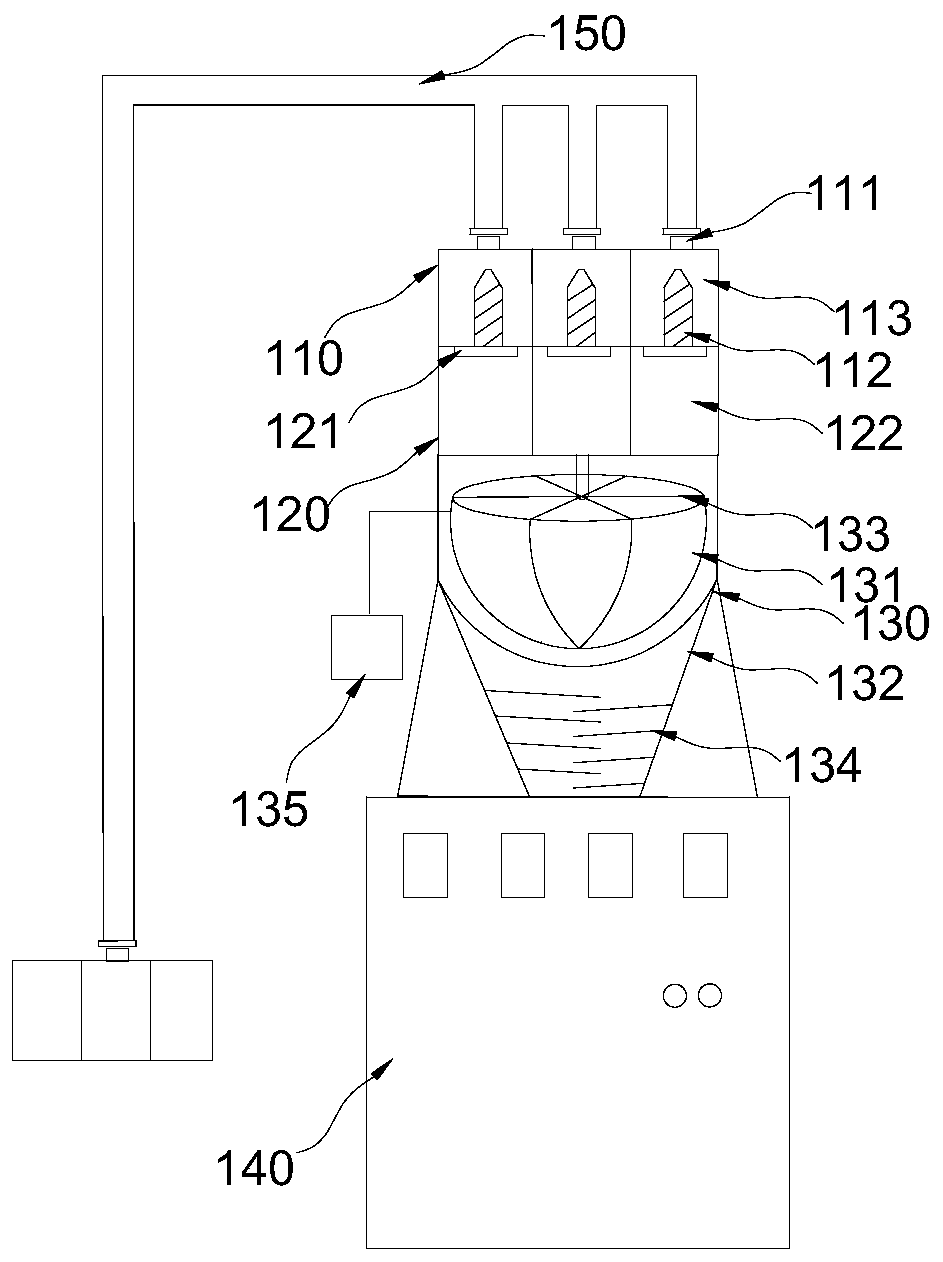

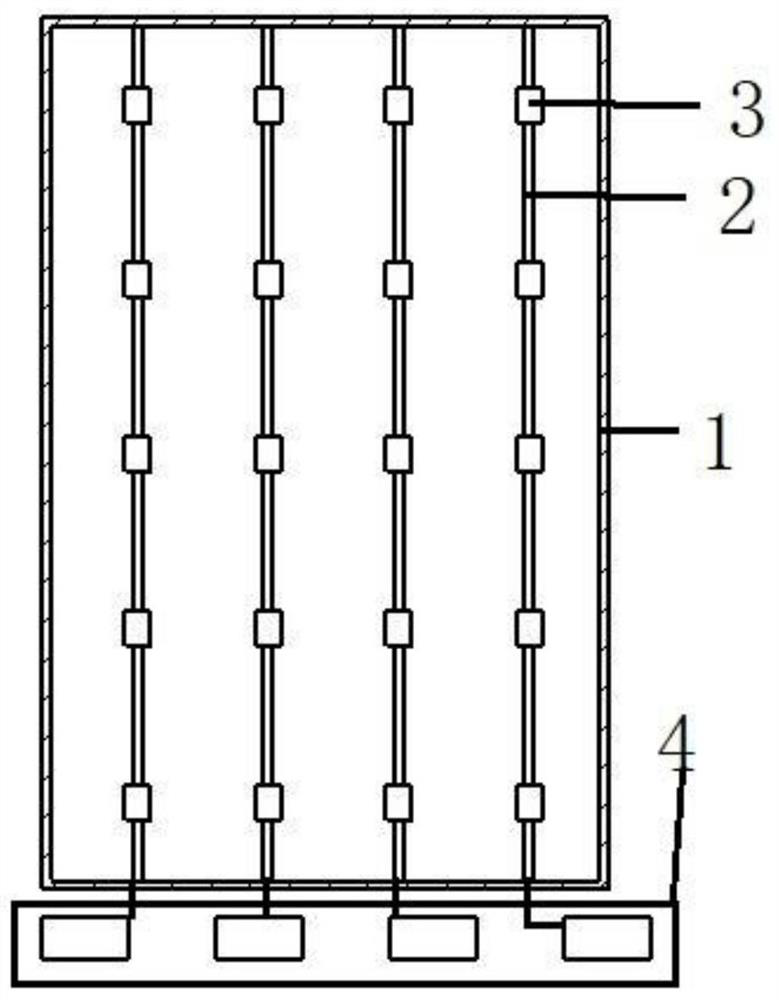

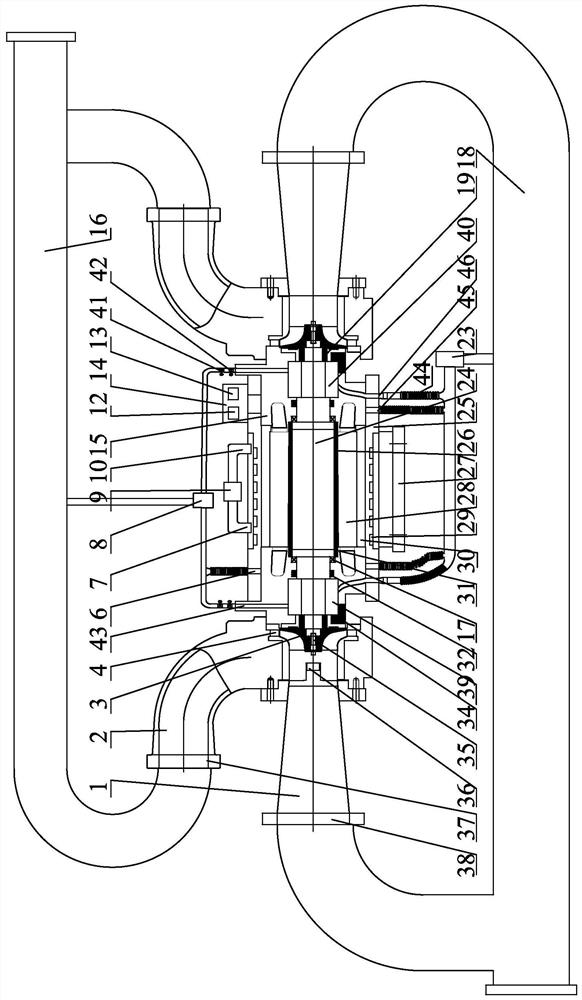

Granulation system for organic composite material master batch

PendingCN110871520AAchieving Controlled Reactive ExtrusionAchieve shear controlCoatingsFluid shearPlasticulture

The invention discloses a granulation system for organic composite material master batch, and belongs to production equipment for the organic composite material master batch. The granulation system comprises a mixing device, an extrusion device, a cooling device, a cutting device, a conveying device and a packaging device which are sequentially connected, wherein the extrusion device comprises a machine housing, an extrusion screw rod arranged in the machine housing, a monitoring part arranged on the extrusion screw rod and a control cabinet connected with the monitoring part; the extrusion screw rod comprises an extrusion feeding section, an extrusion compression section and an extrusion metering section which are sequentially connected; and a feeding hole of the extrusion feeding sectionis connected with a discharging hole of the mixing device. According to the granulation system, the organic composite material master batch is granulated through six processes of mixing, extrusion, cooling, cutting, conveying and packaging, so that accurate control on each process can be realized, controllable reaction extrusion and fluid shearing control of a plasticizing melting area are realized, and controllable reaction extrusion of a polymer melt is realized; and multi-scale controllable mixing of different matrix phases and multi-element systems is realized by accurately controlling ashearing unit, so that the granulation system is simple to operate and high in automation degree.

Owner:CHENGDU RICH SCI IND

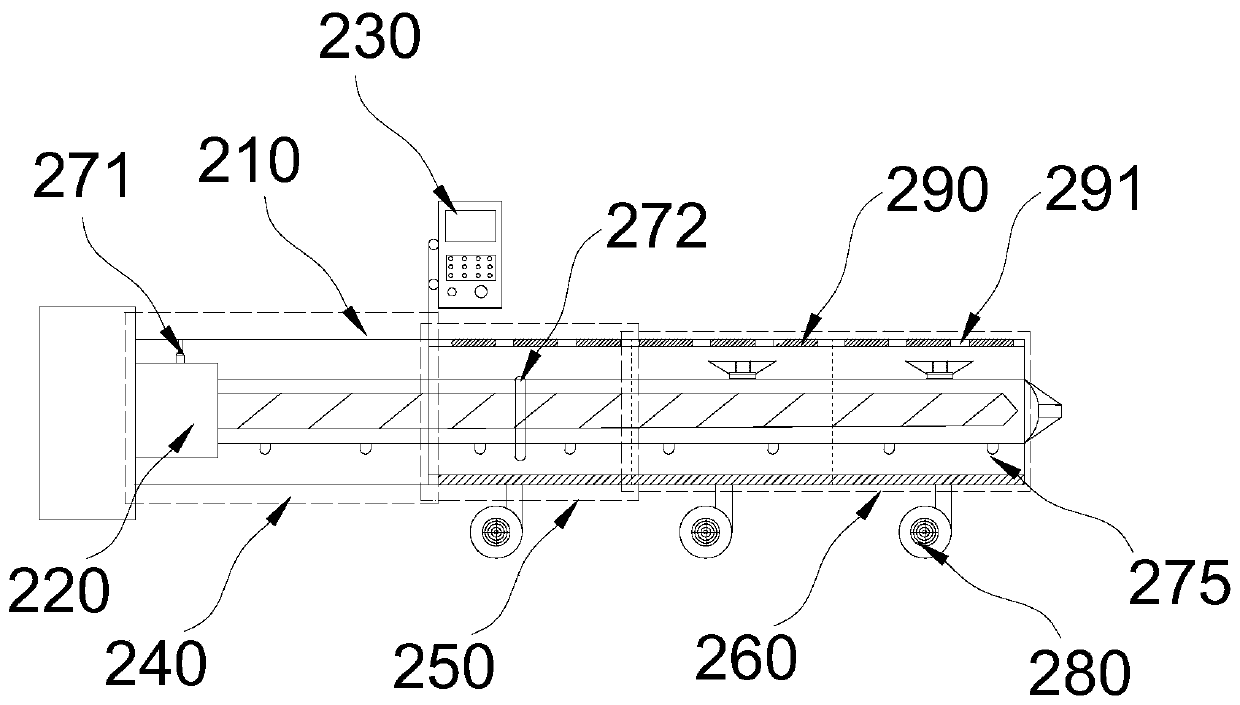

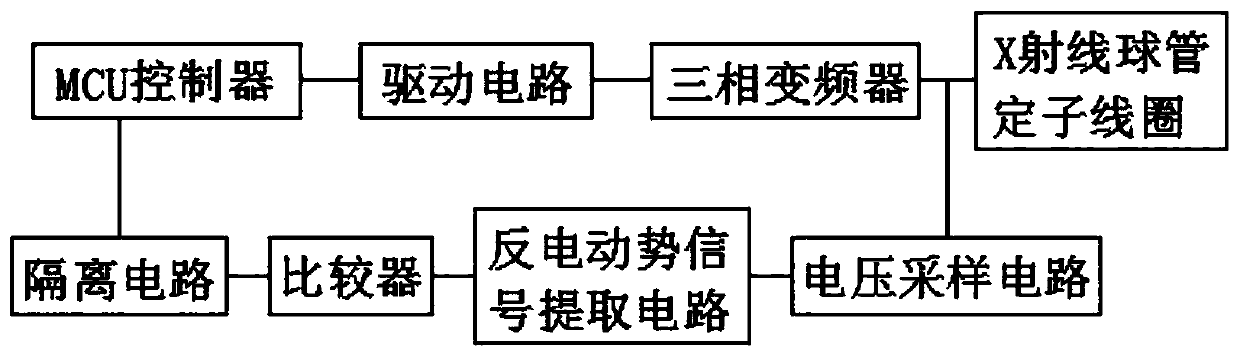

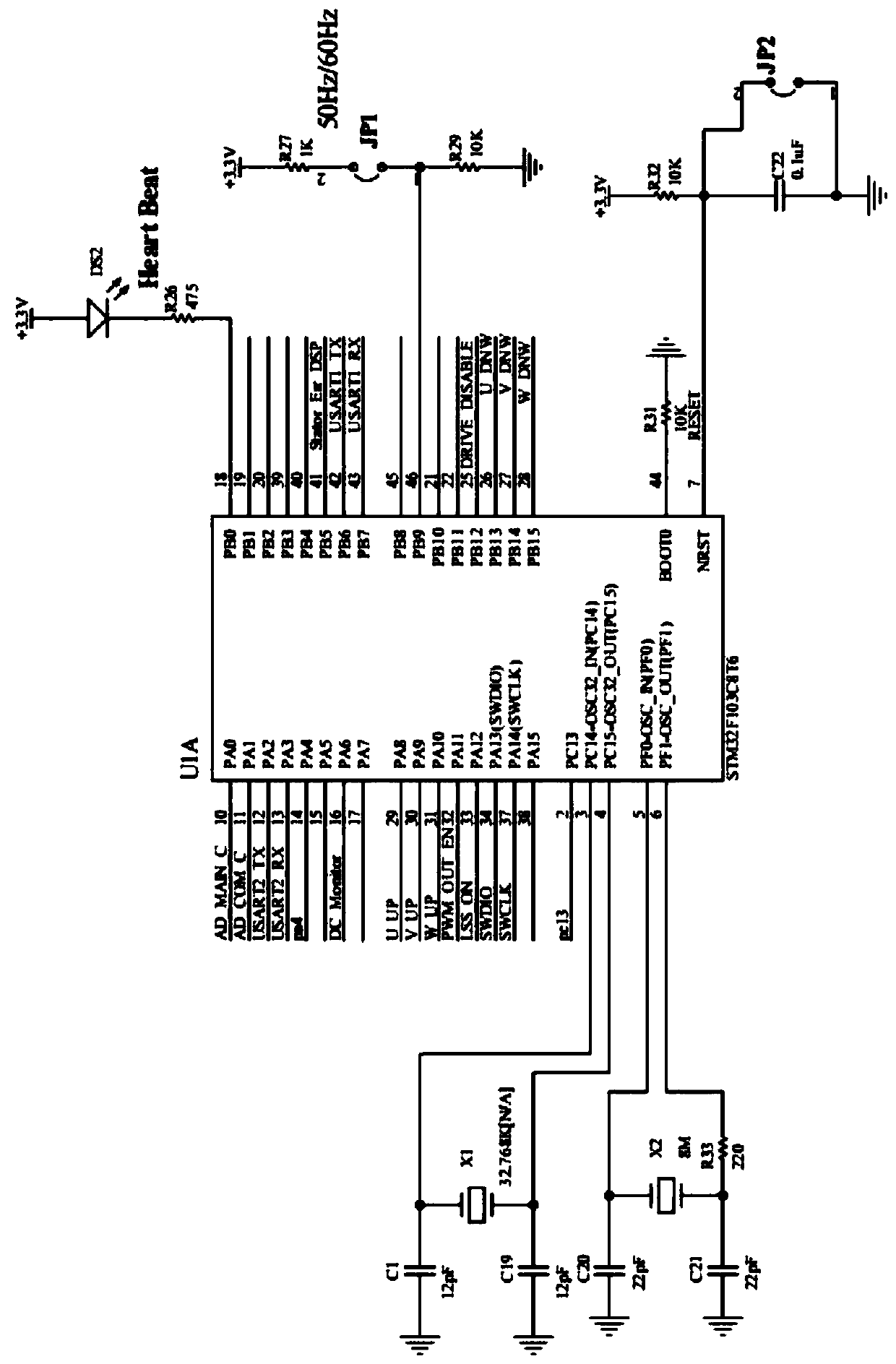

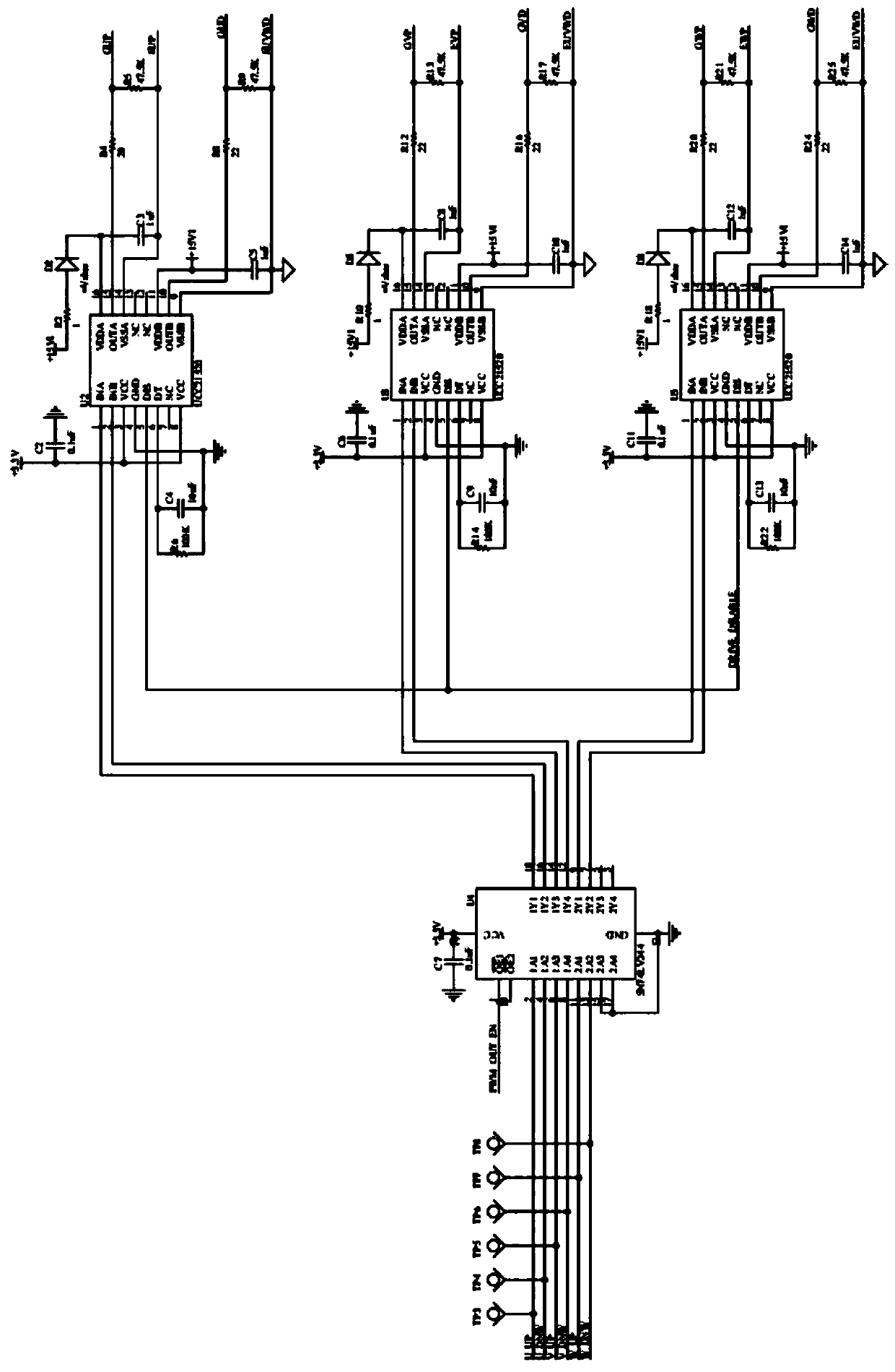

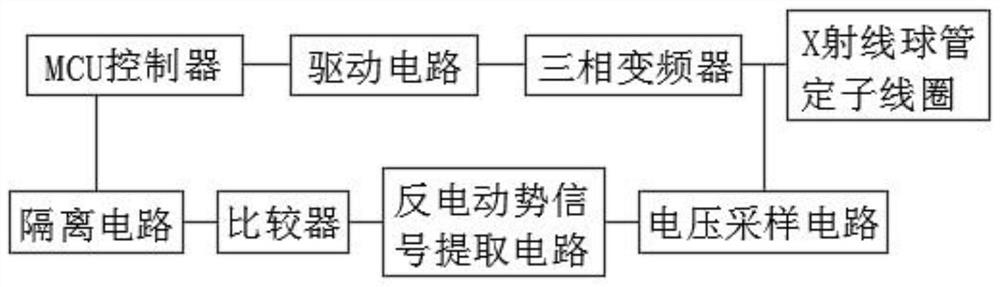

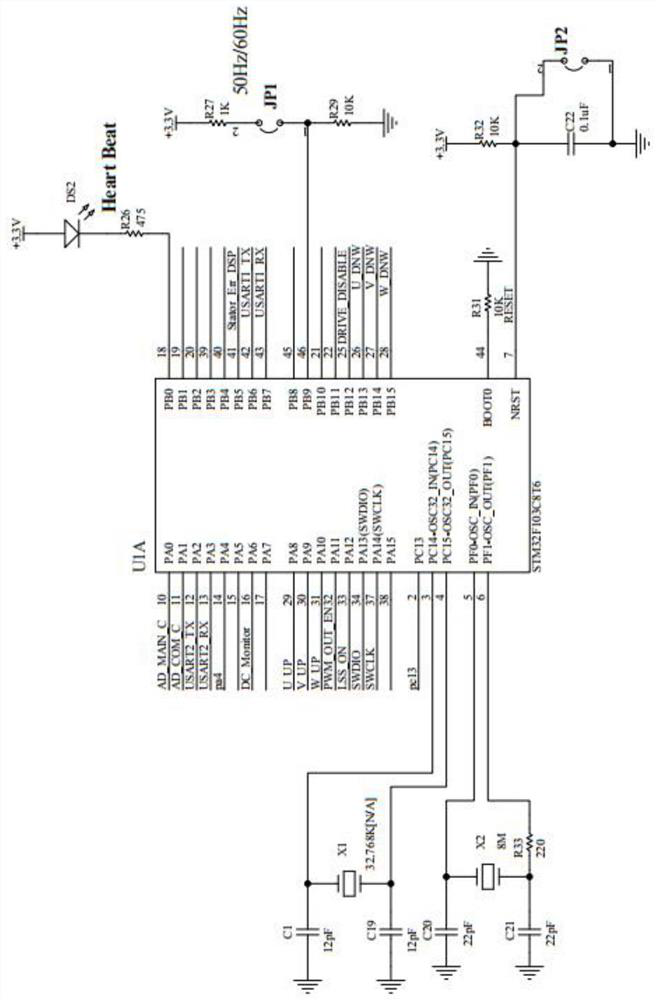

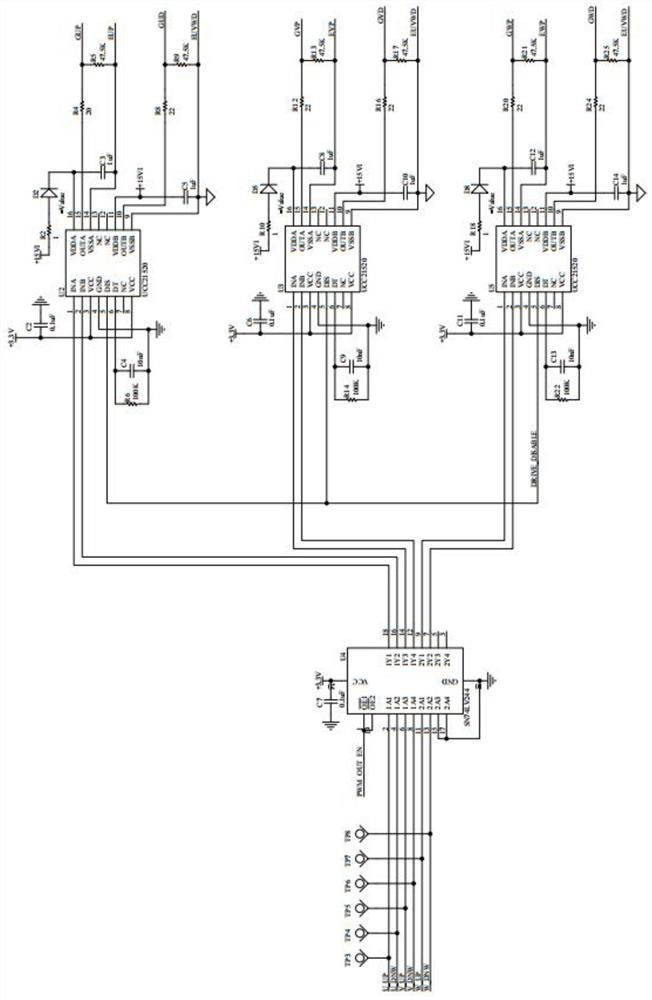

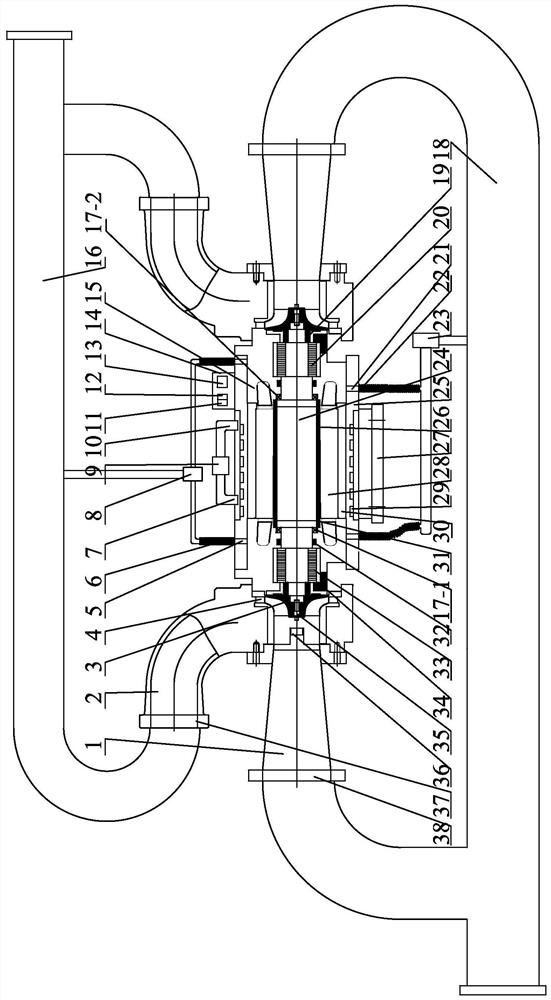

Rotating speed detecting method and device for bulb rotor of rotary anode

ActiveCN110488038AReal-time monitoring of speedAccurate readingProgramme controlComputer controlAC - Alternating currentX-ray

The invention discloses a rotating speed detecting method and device for a bulb rotor of a rotary anode. The method comprises the following steps that S1, an MCU controller intermittently generates anSPWM control sequence through a control algorithm so as to drive a three-phase frequency converter to generate corresponding AC output; S2, three alternating-current output ends of the three-phase frequency converter are connected to an X-ray bulb stator coil so as to drive the X-ray bulb rotor to rotate; and S3, induction voltage is mutually induced from two of the three AC output ends of the three-phase frequency converter so as to acquire a reverse electromotive force voltage with the same frequency as the X-ray bulb rotor. According to the invention, a voltage sampling circuit is embedded into the three-phase frequency converter, rotating speed information of the rotor is obtained through reverse electromotive force in an intervention mode and is read accurately and monitored in realtime, and the problems that the rotating speed of the X-ray bulb rotor is difficult to detect and cannot be detected in real time through a conventional mechanical synchronous vibration detection means, and that reading errors exist are solved.

Owner:博玮科技(北京)有限公司

Rotational speed control system of power motor

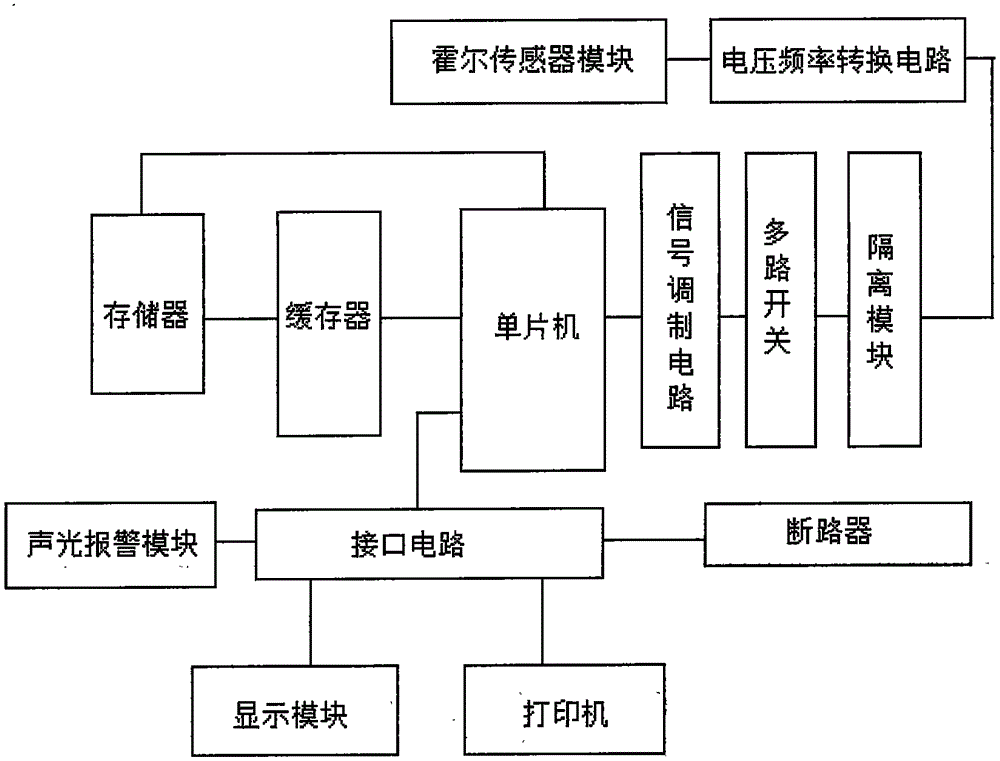

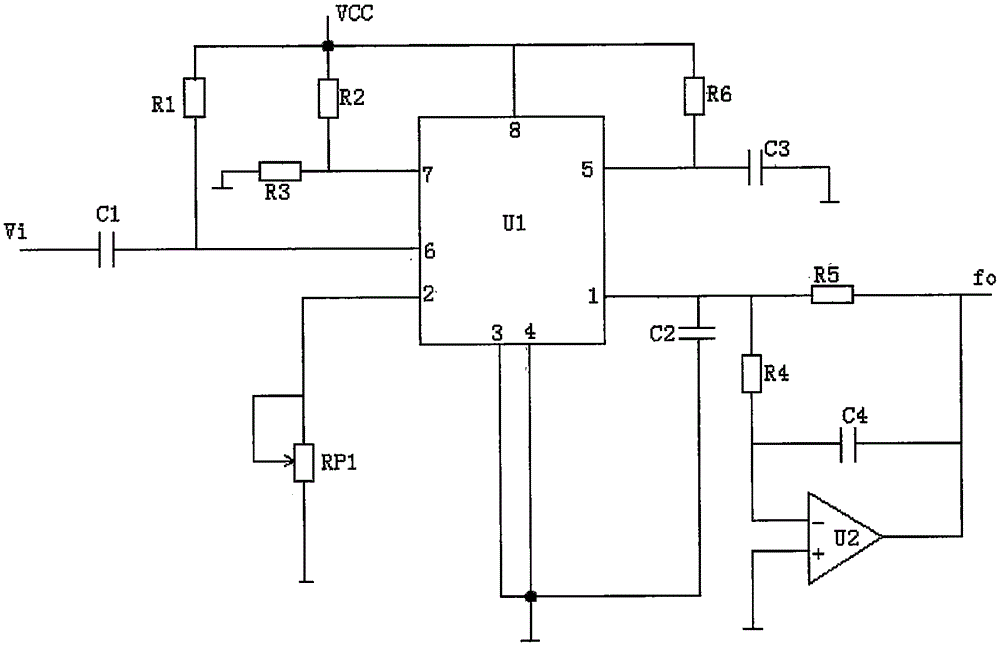

InactiveCN105680766AReal-time monitoring of speedSimple structureElectric motor controlIntegrated circuitInterface circuits

The invention discloses a speed control system for an electric motor, comprising a hall sensor module, a voltage-frequency conversion circuit, an isolation module, a single chip, a signal modulation circuit, a buffer, an interface circuit and a circuit breaker. The hall sensor module sequentially passes the voltage The frequency conversion circuit, the multi-way switch, and the signal modulation circuit are connected to the single-chip microcomputer. The single-chip computer is also connected to the memory, the buffer and the interface circuit. The memory is also connected to the buffer. The interface circuit is also connected to the sound and light alarm module, display module, printer and circuit breaker. The power motor speed control system of the present invention uses an isolation module for voltage isolation, and uses a single-chip microcomputer for data processing, speed display, over-limit alarm and control circuit breaker opening, thereby realizing real-time monitoring of the power motor speed. The system has a simple structure and low cost. small volume.

Owner:国网山东郓城县供电公司

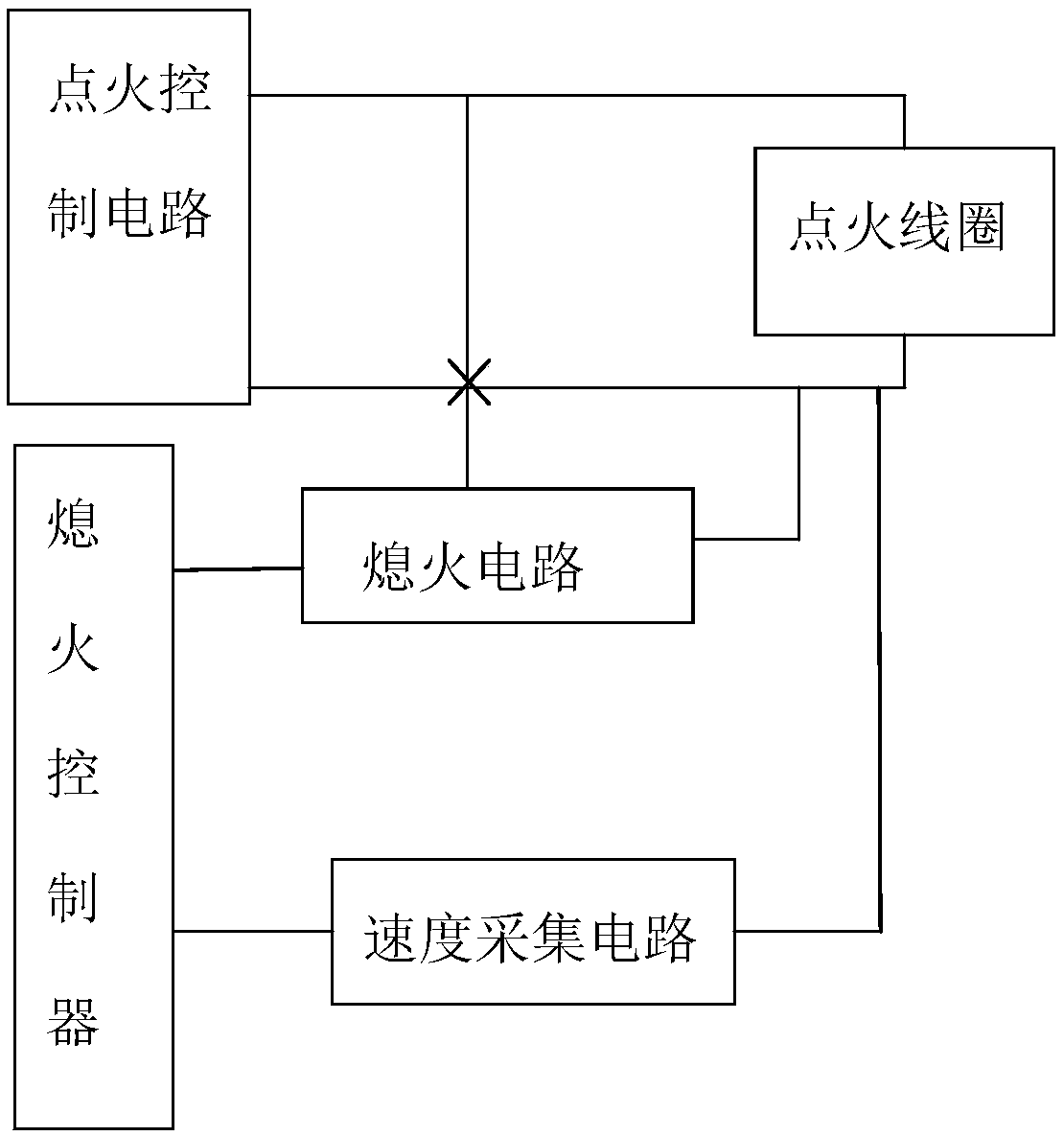

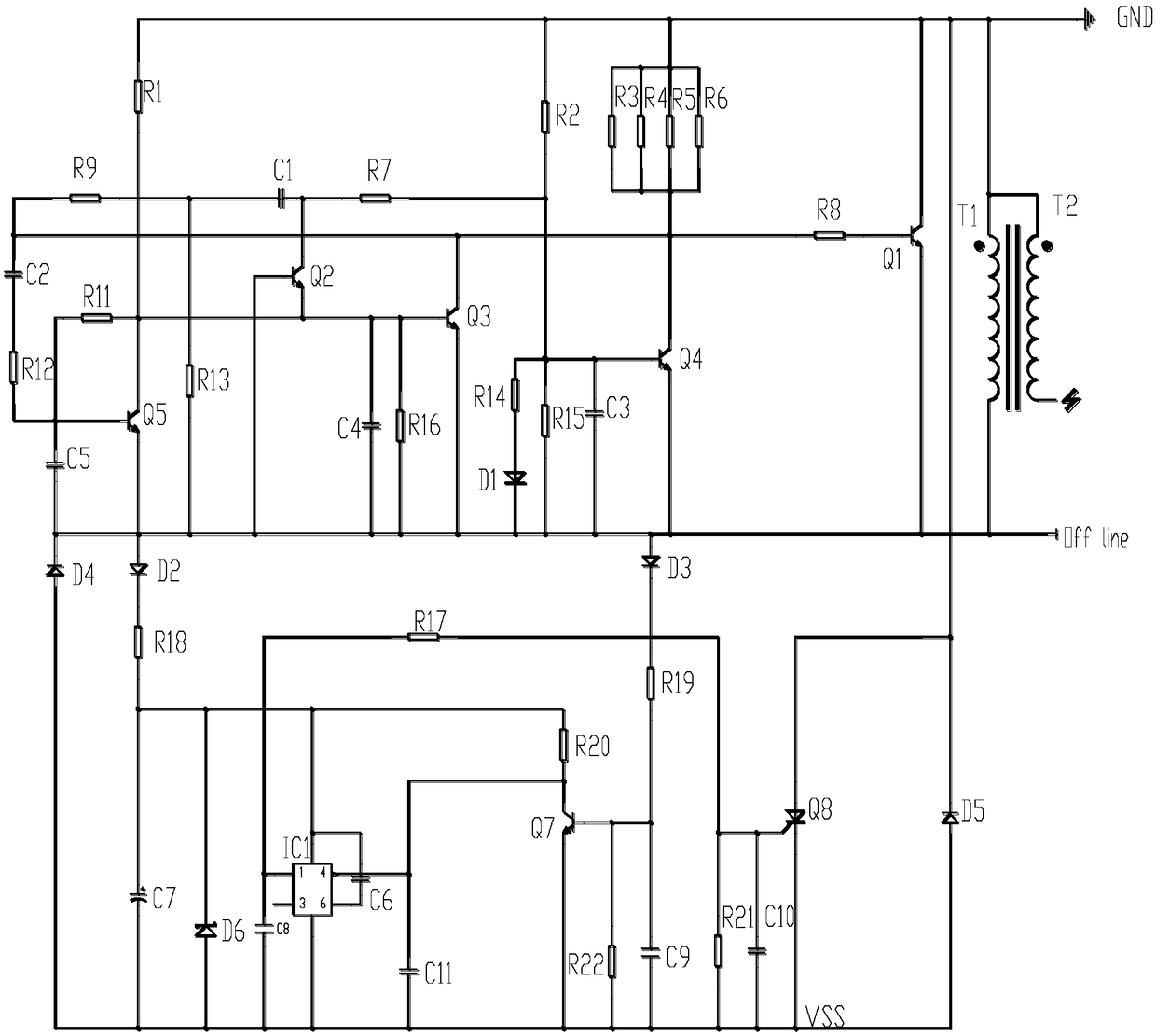

TCI igniter circuit with speed limiting function

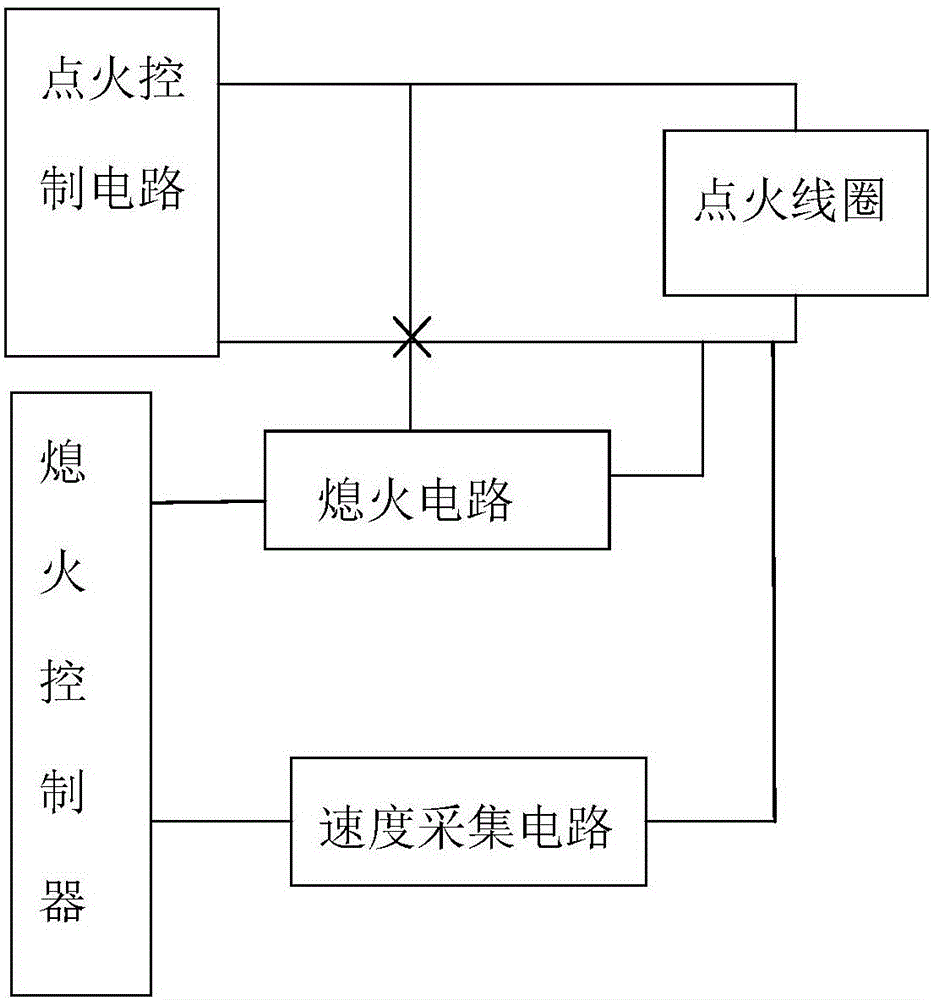

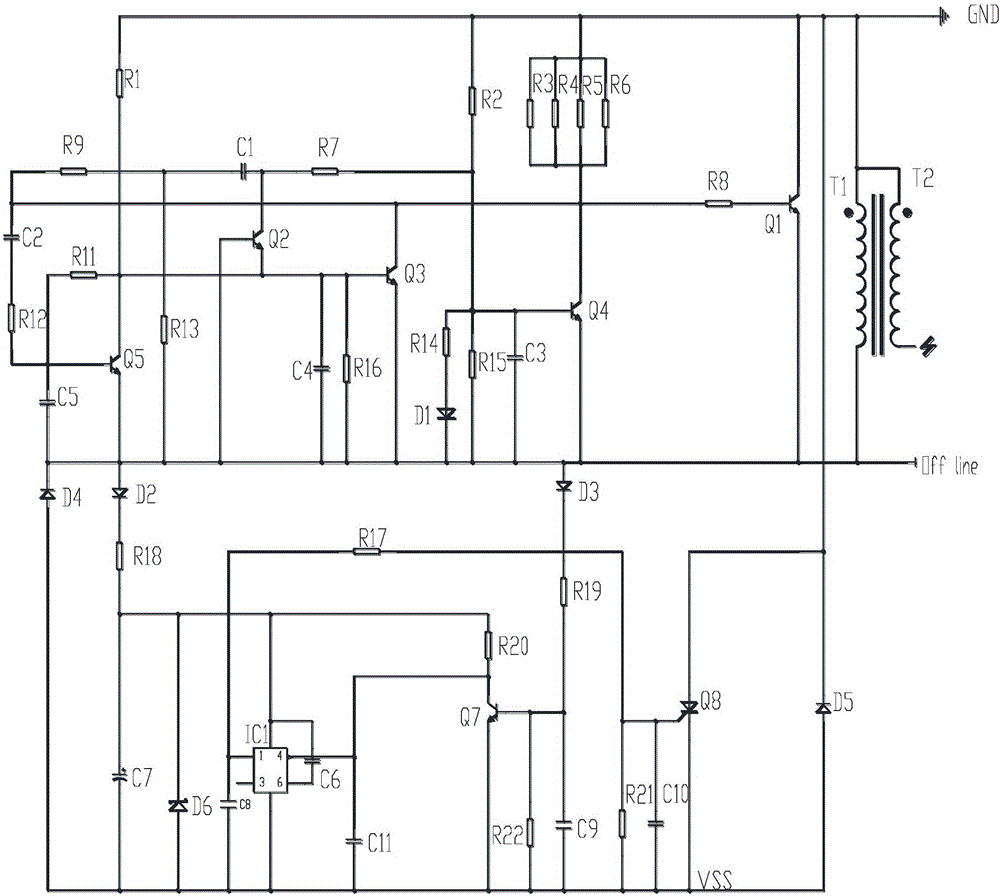

ActiveCN106523240ASimple structureMake up for the errorMachines/enginesIgnition automatic controlIgnition coilControl circuit

A TCI igniter circuit with a speed limiting function comprises an ignition control circuit and an ignition coil. The two ends of the ignition coil are connected with a flame-out line and a GND end correspondingly. The TCI igniter circuit further comprises a flame-out controller. The acquisition end of the flame-out controller is connected with the flame-out line through a speed acquisition circuit. The control end of the flame-out controller is connected with the input end of the flame-out control circuit. An output end set of the flame-out control circuit is connected with the two ends of the ignition coil correspondingly. The TCI igniter circuit with the speed limiting function is simple in overall structure; and under unified coordination of the flame-out controller, the rotating speed situation of an engine is precisely monitored in real time through a speed acquisition circuit, automatic flame-out control is achieved after the rotating speed gets ultrahigh, ignition control and speed limiting control are effectively integrated, the circuit is simplified, and the cost is lowered.

Owner:CHONGQING YUXIN PINGRUI ELECTRONICS

Server fan speed control system and method

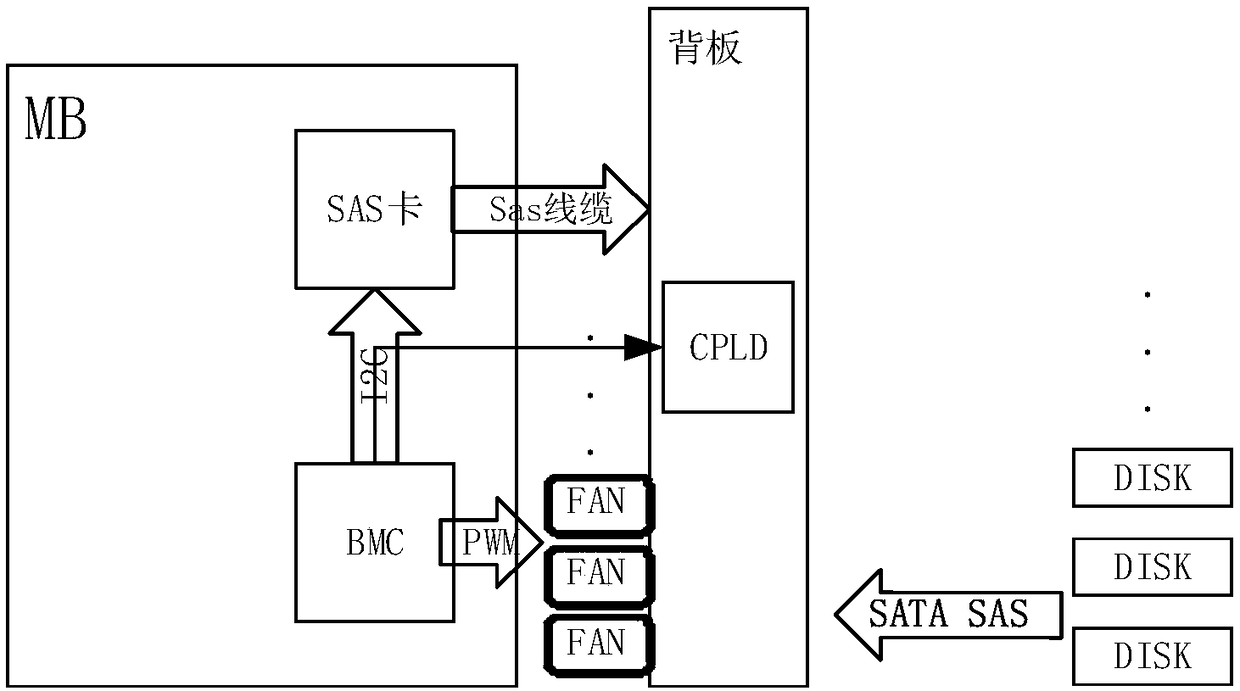

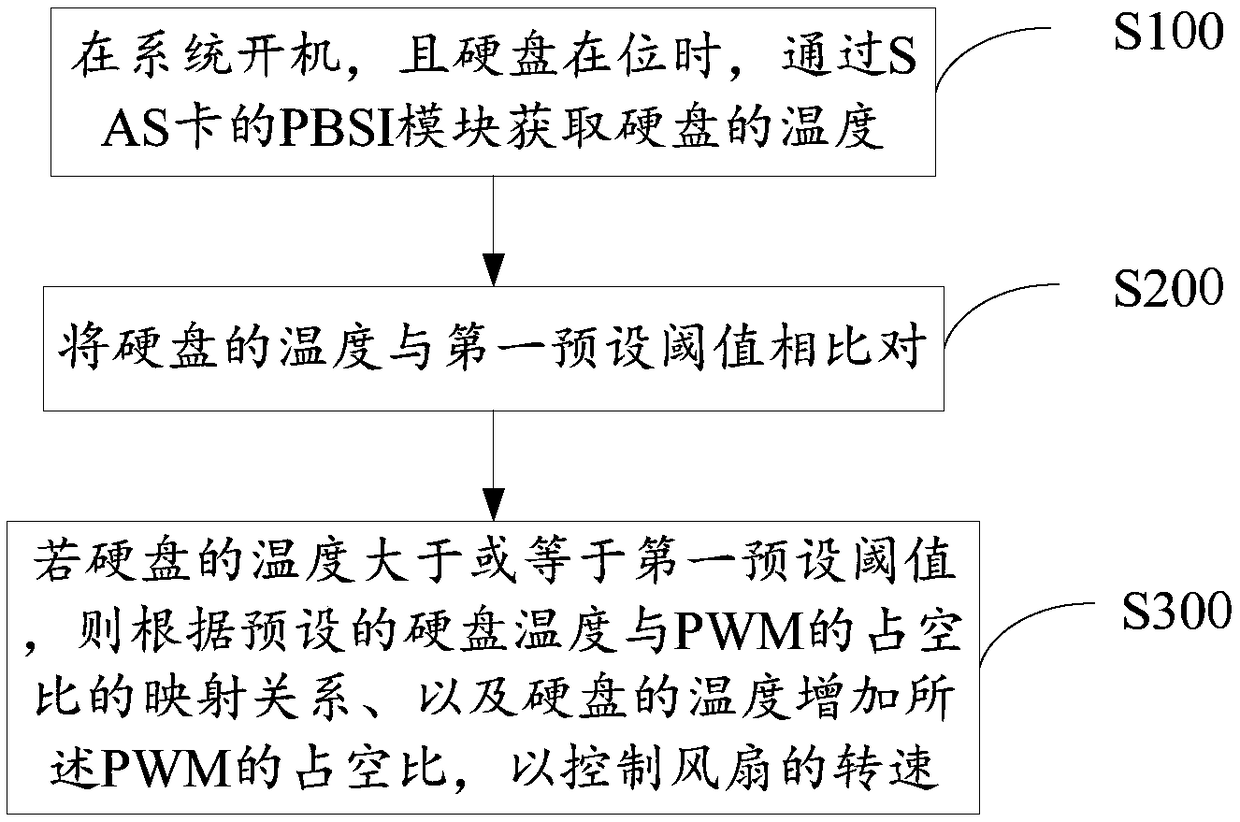

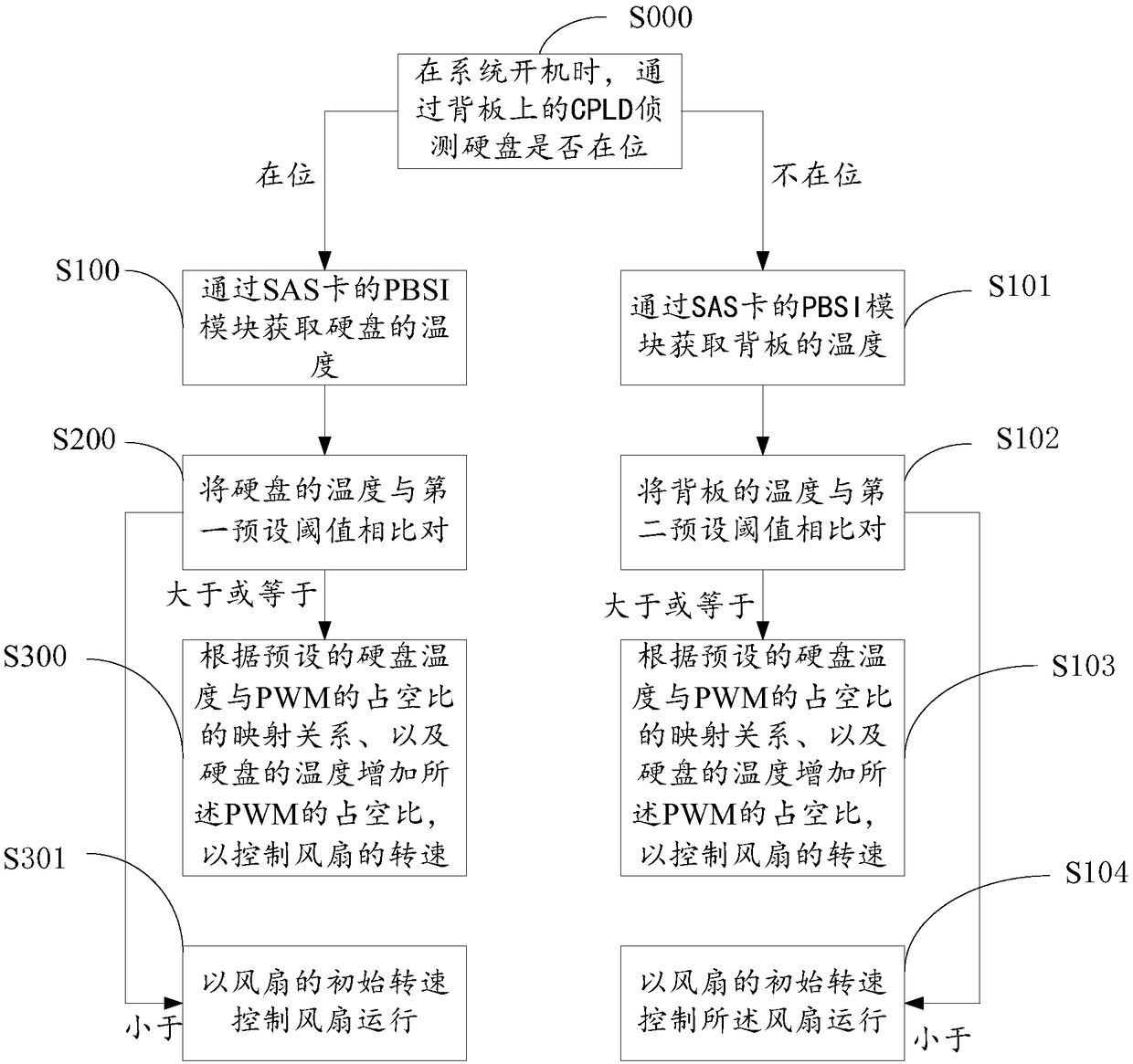

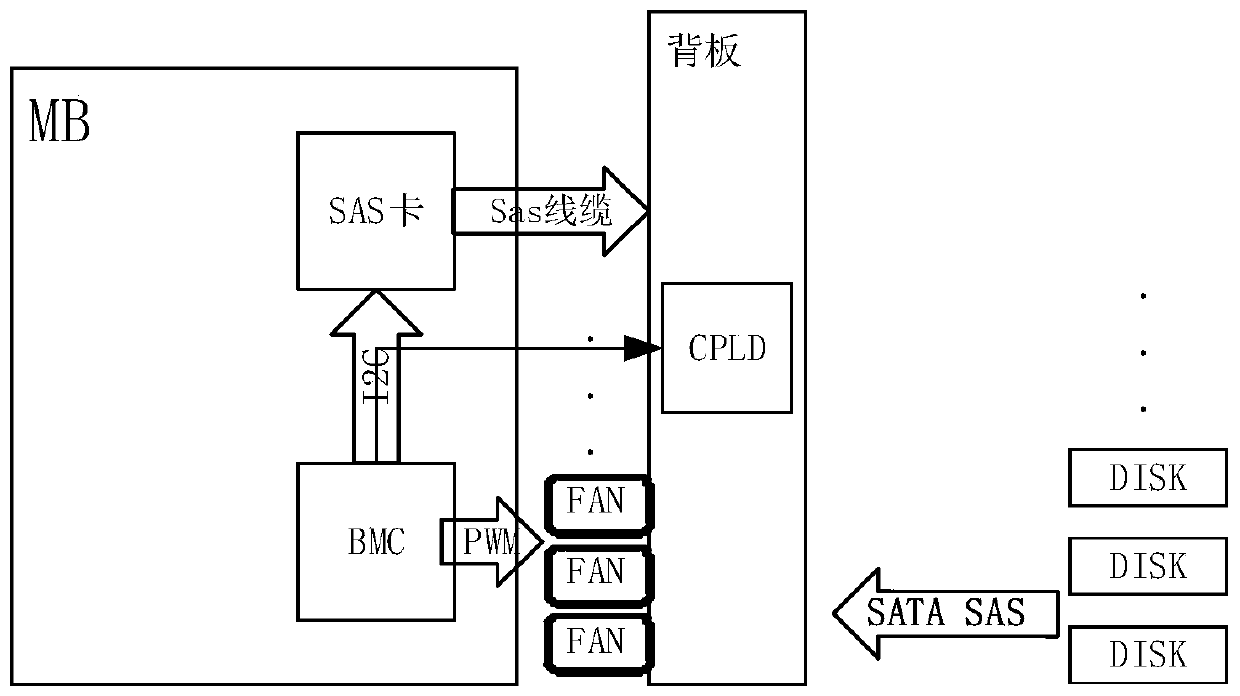

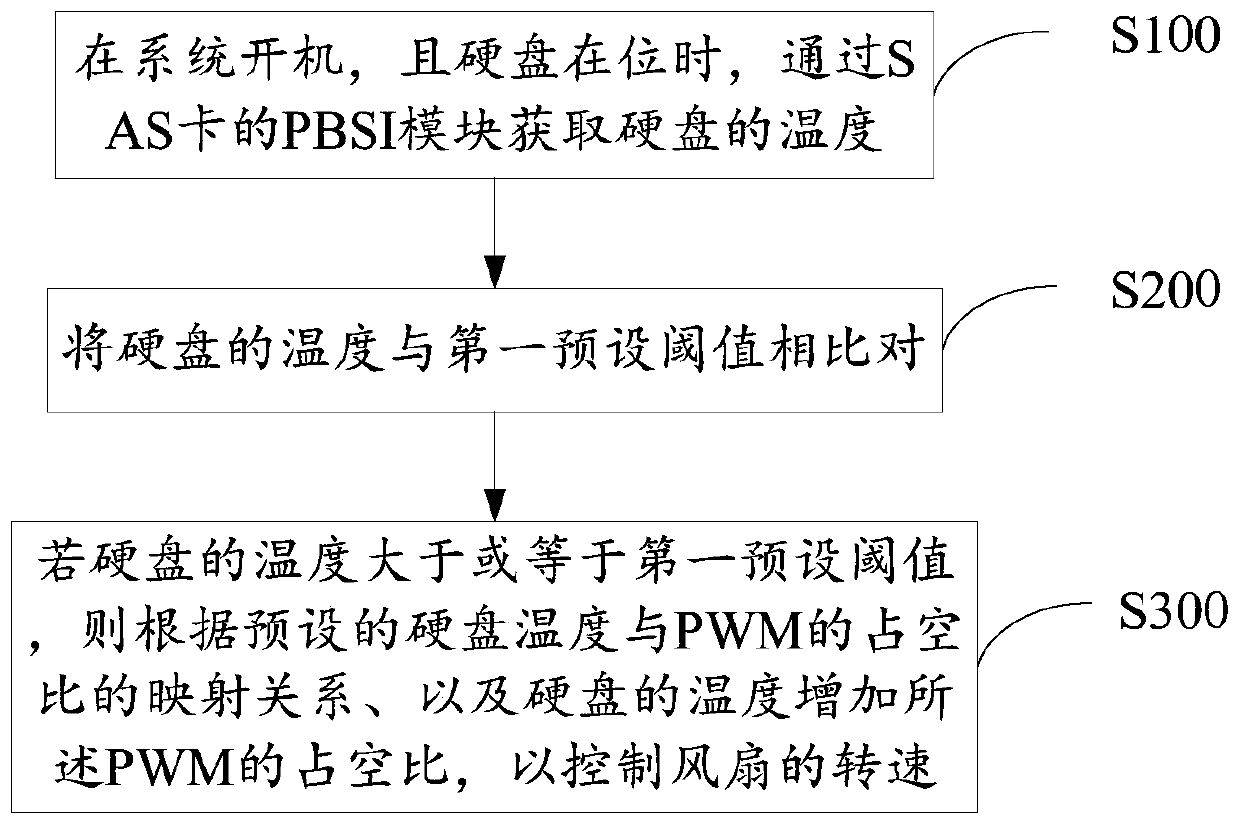

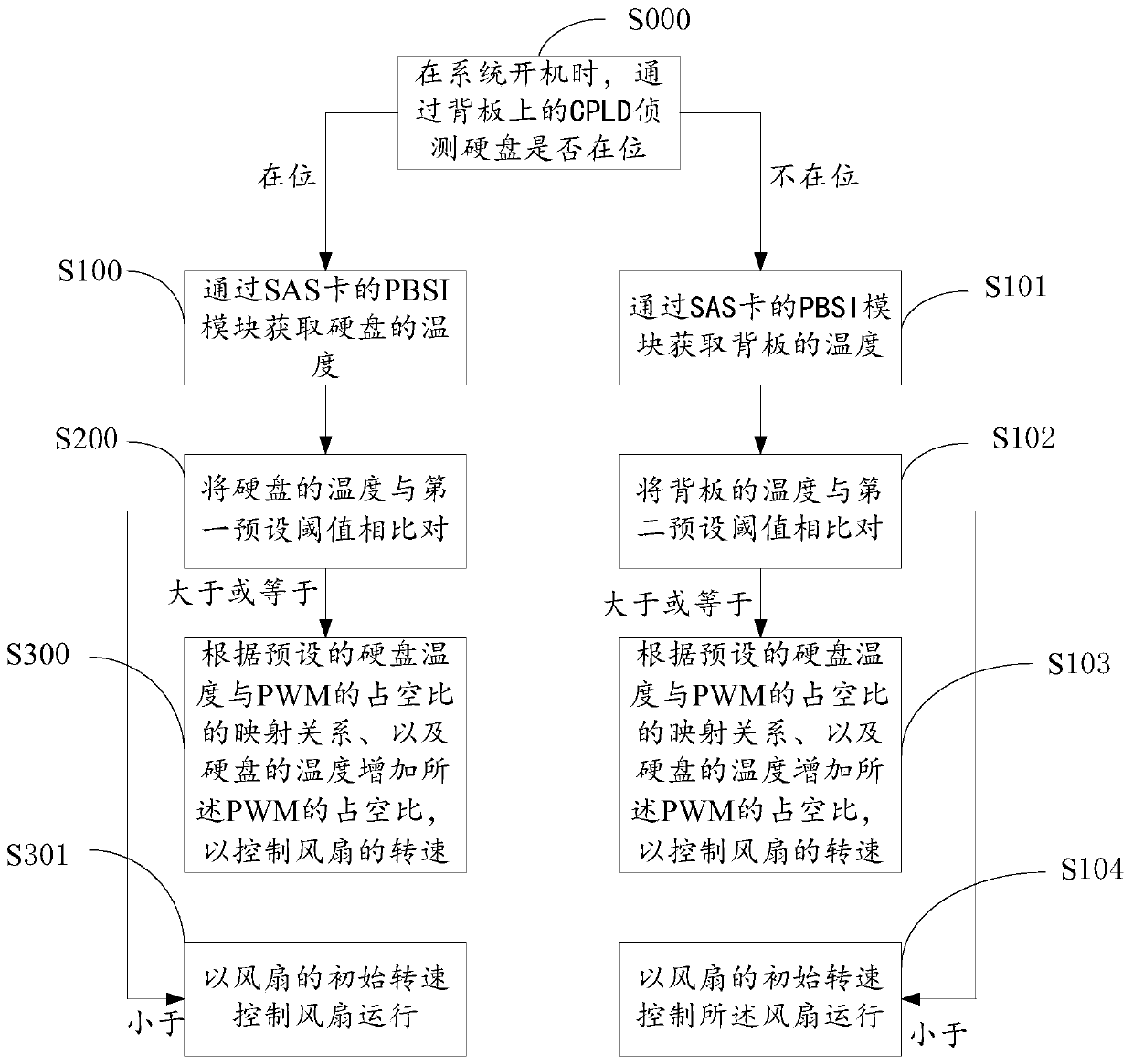

ActiveCN108953205AIncrease duty cycleMonitor temperature in real timeDigital data processing detailsHardware monitoringSpeed control systemControl system

The invention discloses a server fan speed control system and method. The server fan speed control system comprises a BMC, an SAS card connected with the BMC, a back board connected with the SAS card,a CPLD mounted on the back board, and hard disks connected with the back board; a PBSI module is arranged in the SAS card; the BMC is connected with the SAS card and the CPLD through I2C buses; the SAS card is connected with the back board through an SAS wire cable; and the hard disks are connected with the back board through an SATA or SAS interface. Compared with the prior art, the temperaturesof the hard disks can be monitored accurately in real time to adjust a fan speed.

Owner:SHENZHEN TONGTAIYI INFORMATION TECH CO LTD

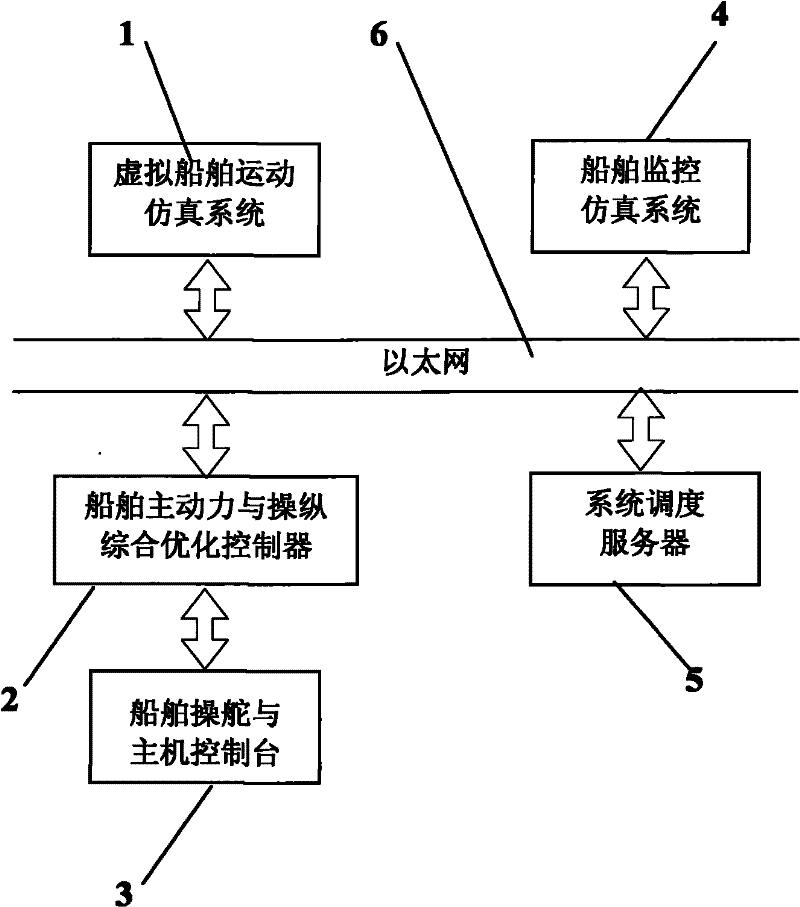

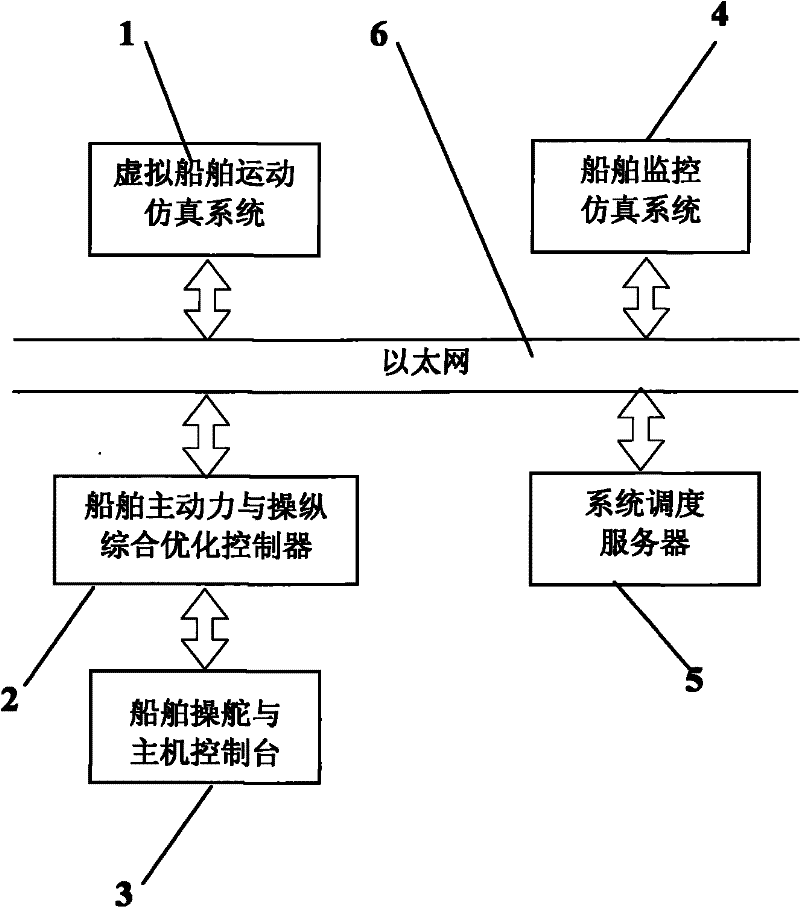

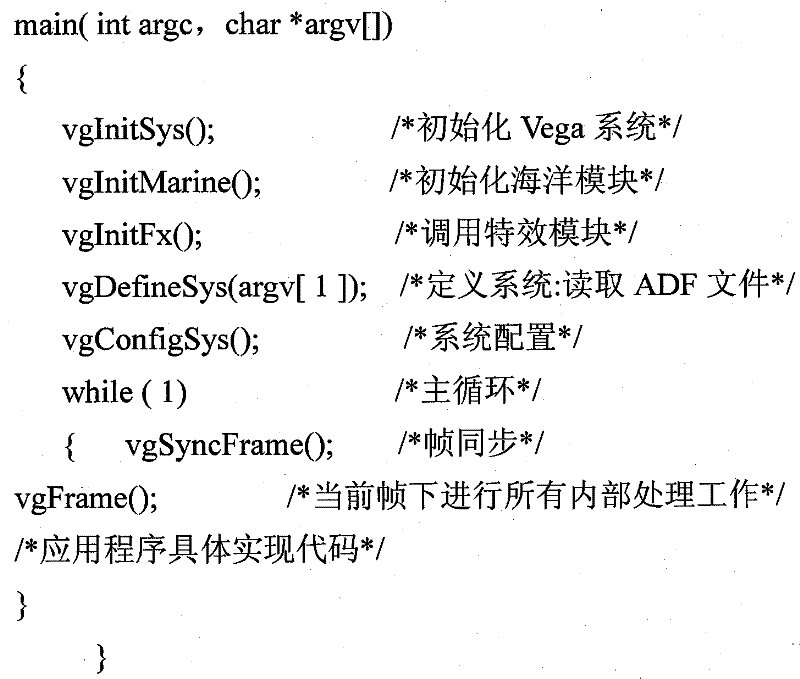

Hardware in-loop simulation system for comprehensive optimization control of main power and manipulation of ship

InactiveCN101819441BRealize automatic navigationCoordination maneuverabilityElectric testing/monitoringWind waveMarine engineering

Owner:DALIAN MARITIME UNIVERSITY

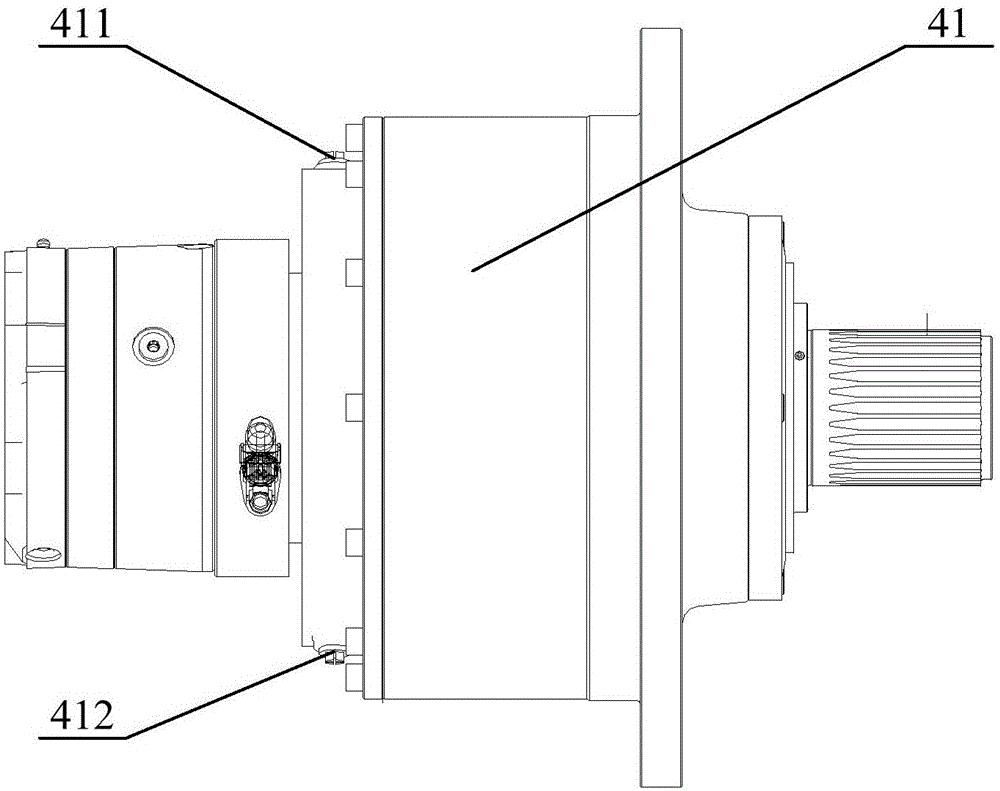

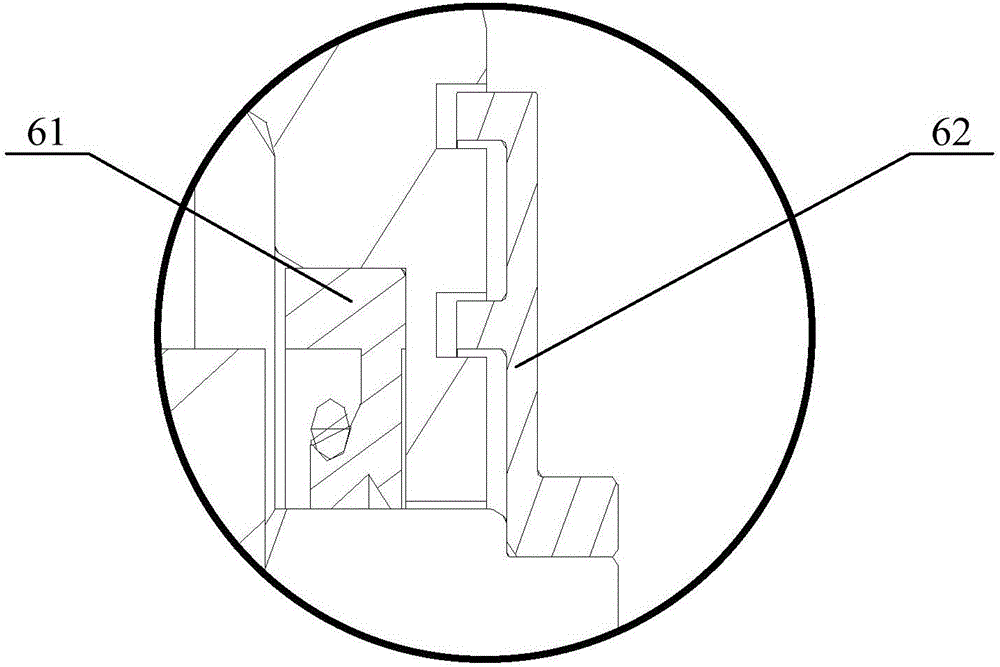

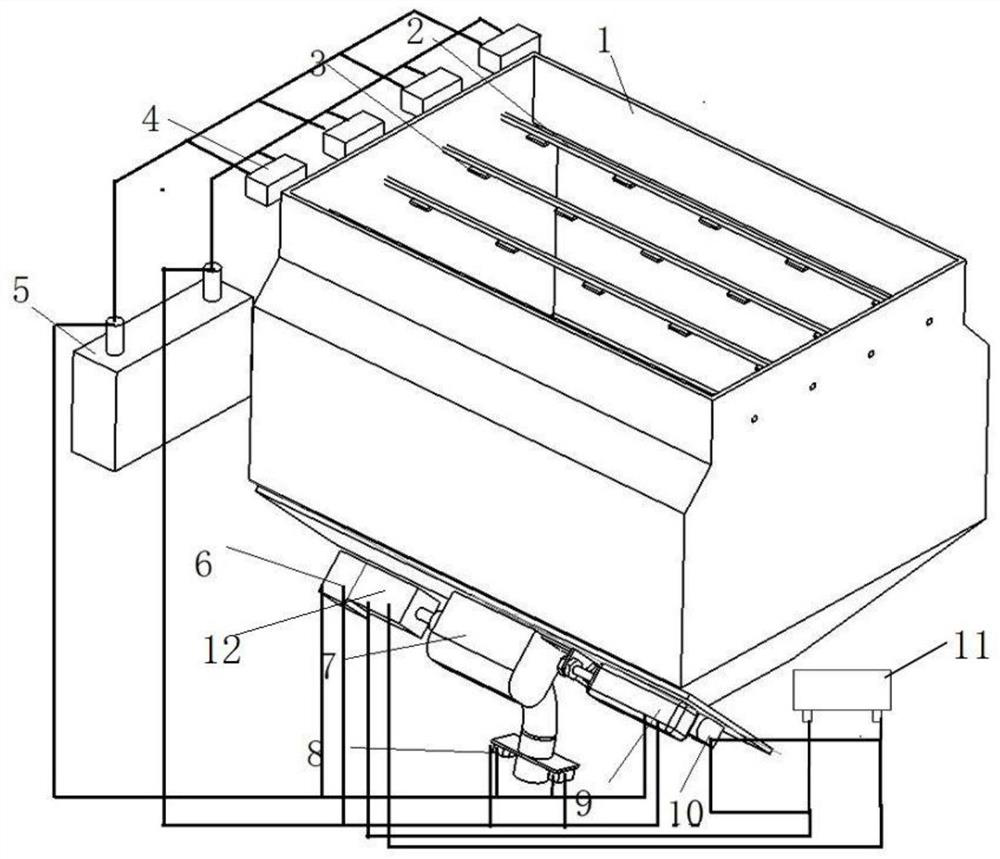

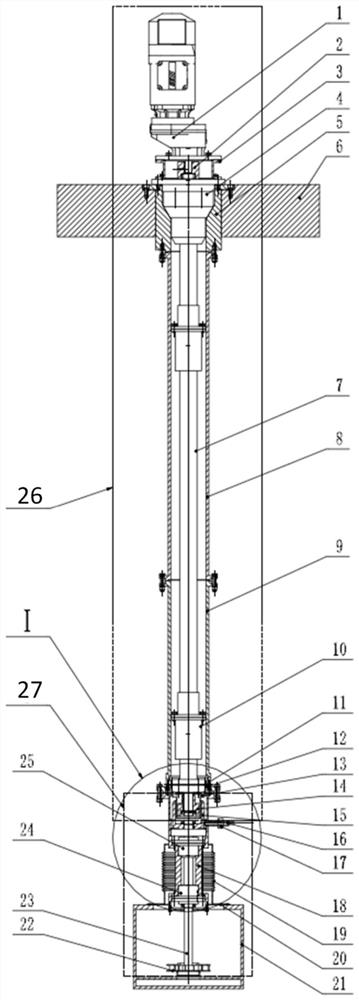

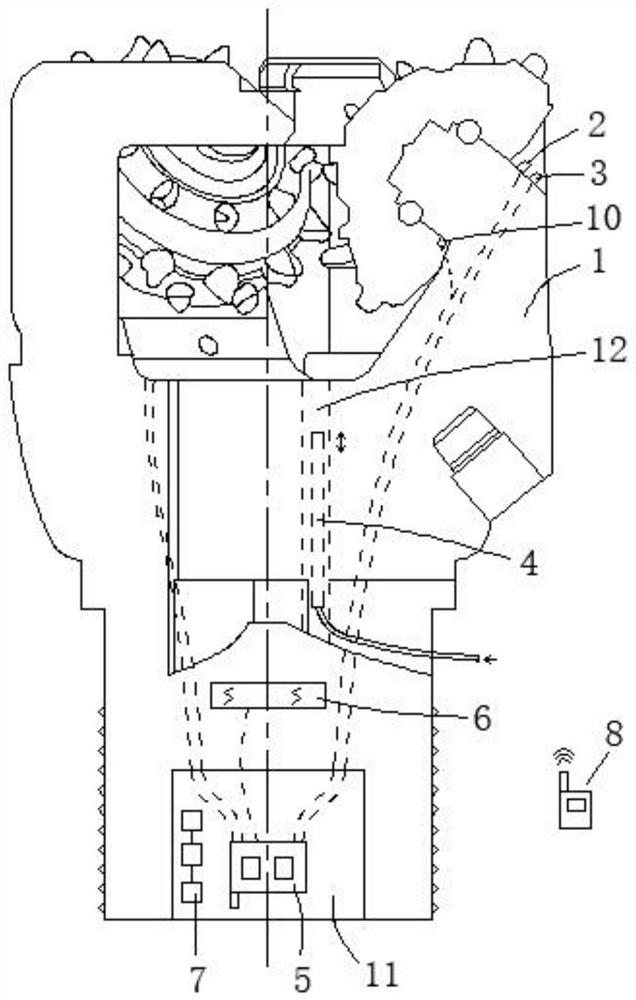

Measurement-while-drilling device applicable to advanced geological prediction for mine roadway

PendingCN108303561AReal-time monitoring speedReal-time monitoring of drilling speedDevices using electric/magnetic meansDrive motorReducer

The invention discloses a measurement-while-drilling device applicable to advanced geological prediction for a mine roadway, which solves a problem that a medium wind pressure and medium depth hole light down-the-hole drill in the prior art cannot accurately master the rotating speed and the drilling speed of a drilling machine in drilling and blasting construction of an underground chamber. The measurement-while-drilling device comprises a driving motor, a reducer, a drilling rod, a first detection gear, a mounting bracket, a first rotating speed sensor, a first intelligent rotating speed digital display instrument, a placement box, a gear shaft, a second detection gear, a second rotating speed sensor and a steel ruler, wherein the second rotating speed sensor is connected with a second intelligent rotating speed digital display instrument; the steel ruler is provided with ruler teeth, the ruler teeth are meshed with gear teeth on the gear shaft, the steel ruler is horizontally arranged in the placement box, and the outer end of the steel ruler is connected with the tail end of the driving motor through a connecting piece. The measurement-while-drilling device is simple in structure, scientific and reasonable in design and convenient to use, can monitor the rotating speed and the drilling rod of the drilling machine and the drilling speed of the drilling machine in real time,and provides accurate data for accurately predicting detailed engineering geological conditions of a drilling area.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Control method of rotating motor

ActiveCN110535402ASafe and reliable controlReliable controlElectric motor controlClosed loopEngineering

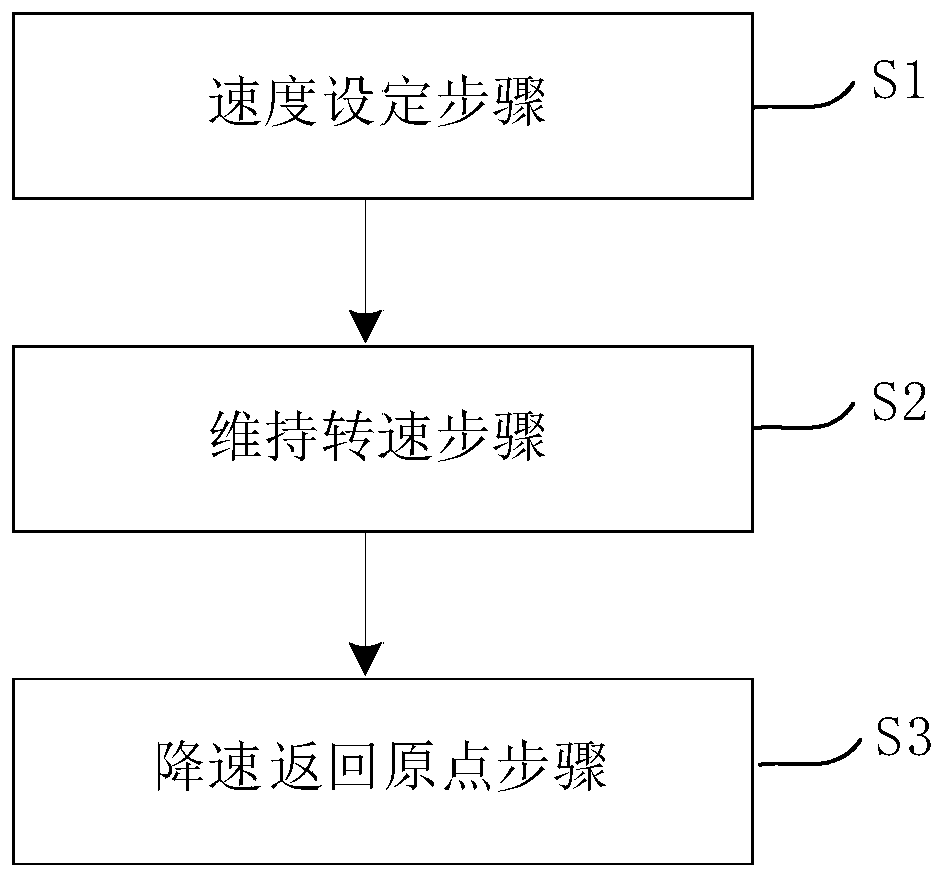

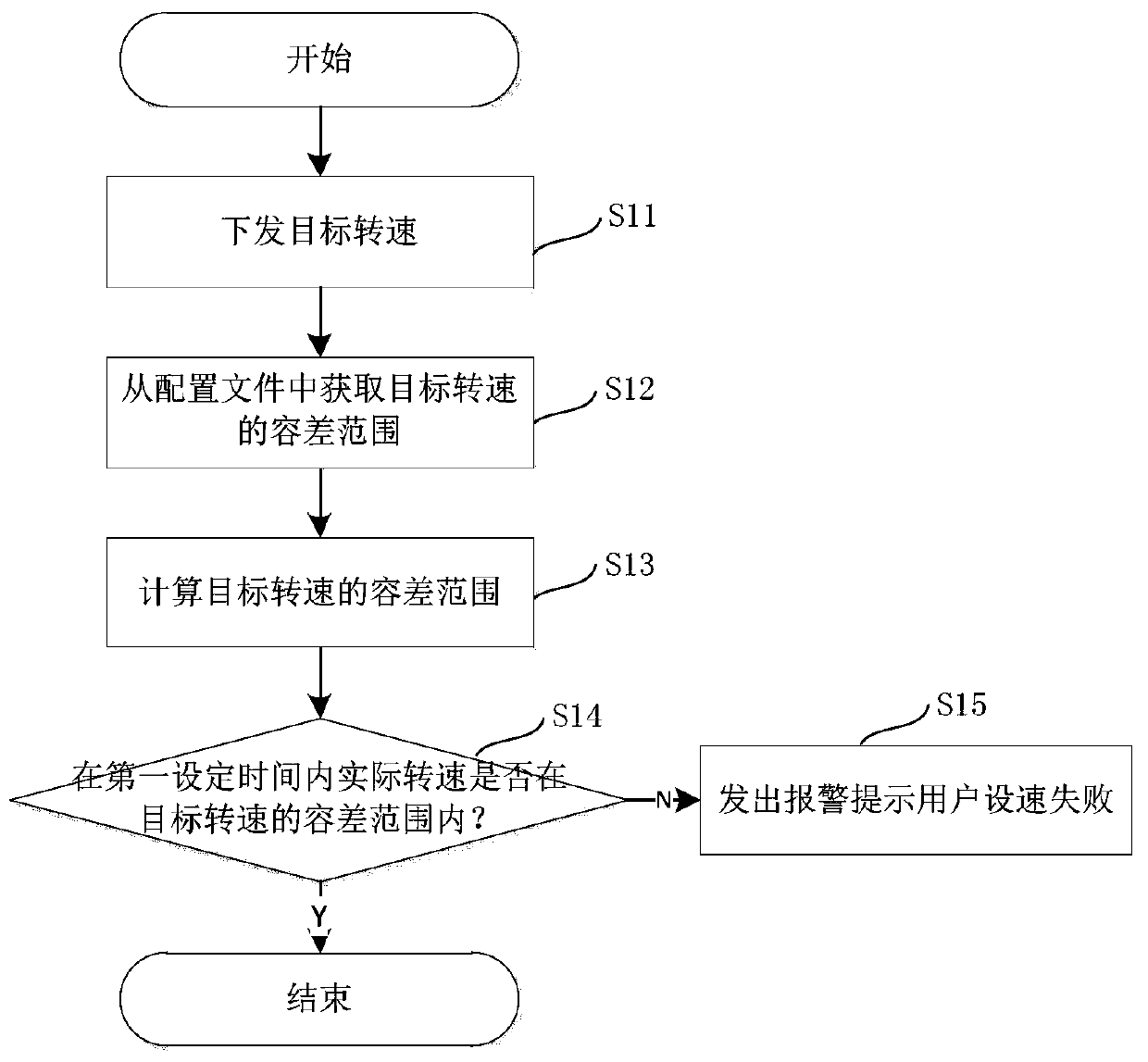

The invention discloses a control method of a rotating motor, which is used for controlling the rotating motor in a machine table rotating device of semiconductor equipment. The control method of a rotating motor comprises the following steps of: a speed setting step of setting a target rotating speed before executing a process menu, and determining whether the speed setting is successful or not by acquiring the rotating speed fed back by the rotating motor in real time; a rotating speed maintaining step for maintaining the rotating speed of the rotating motor in the process of executing the process menu; and a step of reducing the speed and returning to the original point, namely reducing the speed of the rotating motor and returning to the original point after the process menu is executed, and determining whether the rotating motor returns to the original point successfully by acquiring the state fed back by the rotating motor in real time and detecting whether the rotating motor islocated at the original point position or not. In the speed setting step before the process menu is started and the speed reduction original point returning step after the process menu is ended, closed-loop control is adopted for the rotating motor, it is ensured that a control command of the rotating motor is successfully executed, and control over the rotating motor is safer, more reliable and more stable.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Rotary speed reducer and rotary speed reducer for walking

PendingCN106641217AImproved thermal equilibrium stabilityAvoid enteringGear lubrication/coolingToothed gearingsReducerControl theory

The invention discloses a rotary speed reducer and a rotary speed reducer for walking, and relates to the technical field of speed reducers. The rotary speed reducer comprises an input spline sleeve connected with an output spline shaft through a planet mechanism assembly, wherein a cooling mechanism is arranged near the input spline sleeve; and the cooling mechanism is used for forcedly refrigerating lubricating oil in a box body of the rotary speed reducer. The technical problem that a rotary speed reducer in the prior art cannot serve as a walking speed reducer can be solved through the rotary speed reducer.

Owner:SUOTE TRANSMISSION EQUIP

A method and device for detecting the rotational speed of a rotating anode bulb tube rotor

ActiveCN110488038BReal-time monitoring of speedAccurate readingProgramme controlComputer controlFrequency changerStator coil

The invention discloses a method and device for detecting the rotational speed of a rotating anode bulb tube rotor. The rotational speed detection method includes the following steps: S1: an MCU controller intermittently generates a SPWM control sequence through a control algorithm to drive a three-phase frequency converter to generate a corresponding AC output; S2: The three AC output terminals of the three-phase inverter are connected to the stator coil of the X-ray tube to drive the rotor of the X-ray tube to rotate; S3: Two AC output terminals of the three AC output terminals of the three-phase inverter The induced voltage is mutually induced to obtain the back electromotive voltage with the same frequency as the X-ray tube rotor. The present invention embeds a voltage sampling circuit in a three-phase frequency converter, obtains rotor speed information by means of an intervention method using reverse electromotive force, has the functions of accurate readings and real-time monitoring of the rotor speed, and solves the problem that the rotor speed of an X-ray tube is difficult to detect and The conventional mechanical synchronous vibration detection method cannot detect the rotor speed in real time and there are reading errors.

Owner:博玮科技(北京)有限公司

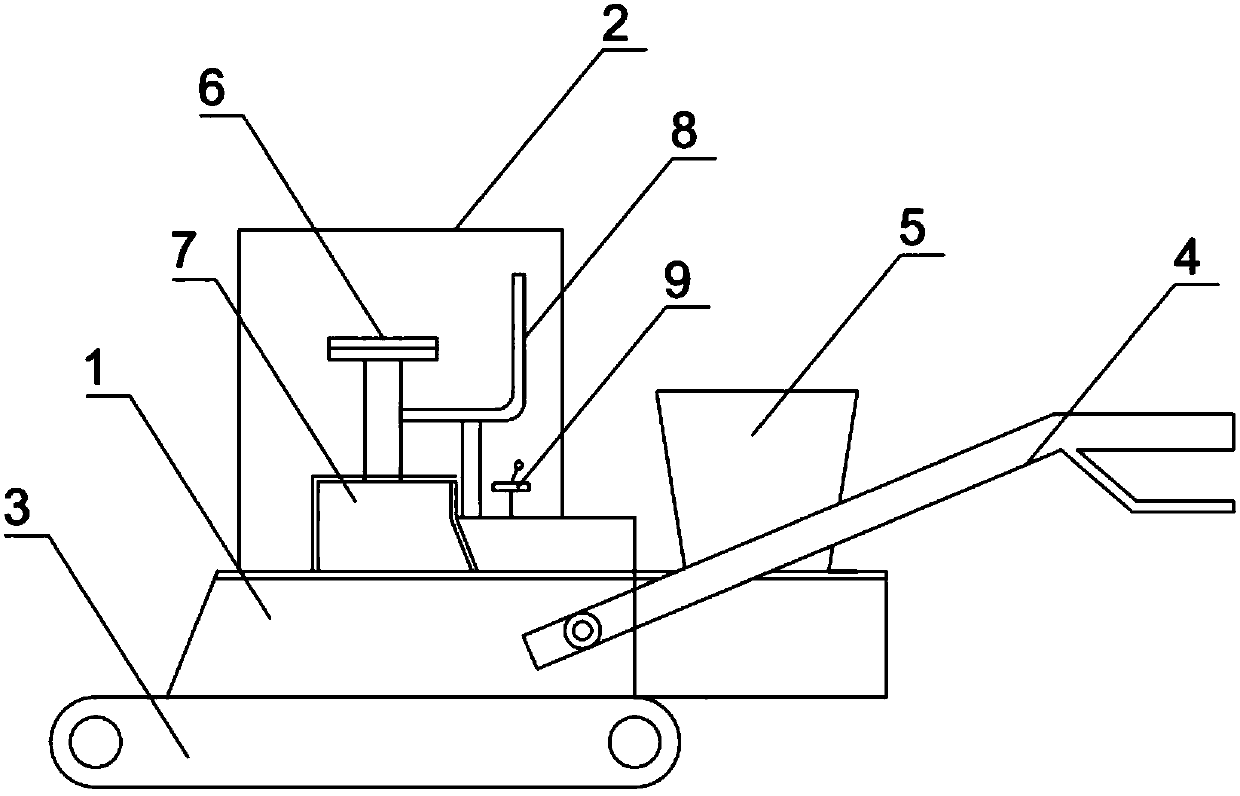

Program-control hydraulic harvester

InactiveCN110100565AReal-time monitoring of speedSimple structural designMowersControl systemAir temperature

The invention discloses a program-control hydraulic harvester. The program-control hydraulic harvester is characterized by comprising a harvester frame, a control chamber, a walking caterpillar band,a handlebar, a hopper, a control panel, a hydraulic control system, a seat and a rocking bar; the walking caterpillar band is connected with the harvester frame, so that the walking progress and speedof the harvester are controlled, and the harvester runs stably; the hydraulic control system is connected with the control panel and the rocking bar through a bus, and monitors the hopper, harvestingand lifting transporting and the state of an engine in real time separately. According to the program-control hydraulic harvester, the control chamber is internally provided with an operation panel which is simple and clear, and the harvester is convenient to use; through the bus, the hopper, the engine and the harvester are connected; through the hydraulic control system, the rotation speed, forward and reverse rotation and lifting transportation height of the harvester are controlled, the automation degree is high, the control system is internally provided with three parts of controllers, the state of the engine is controlled comprehensively, and an engine throttle, the air temperature and the rotation speed of the engine are monitored in real time; the program-control hydraulic harvester is safe, reliable and high in popularization degree.

Owner:陈志新

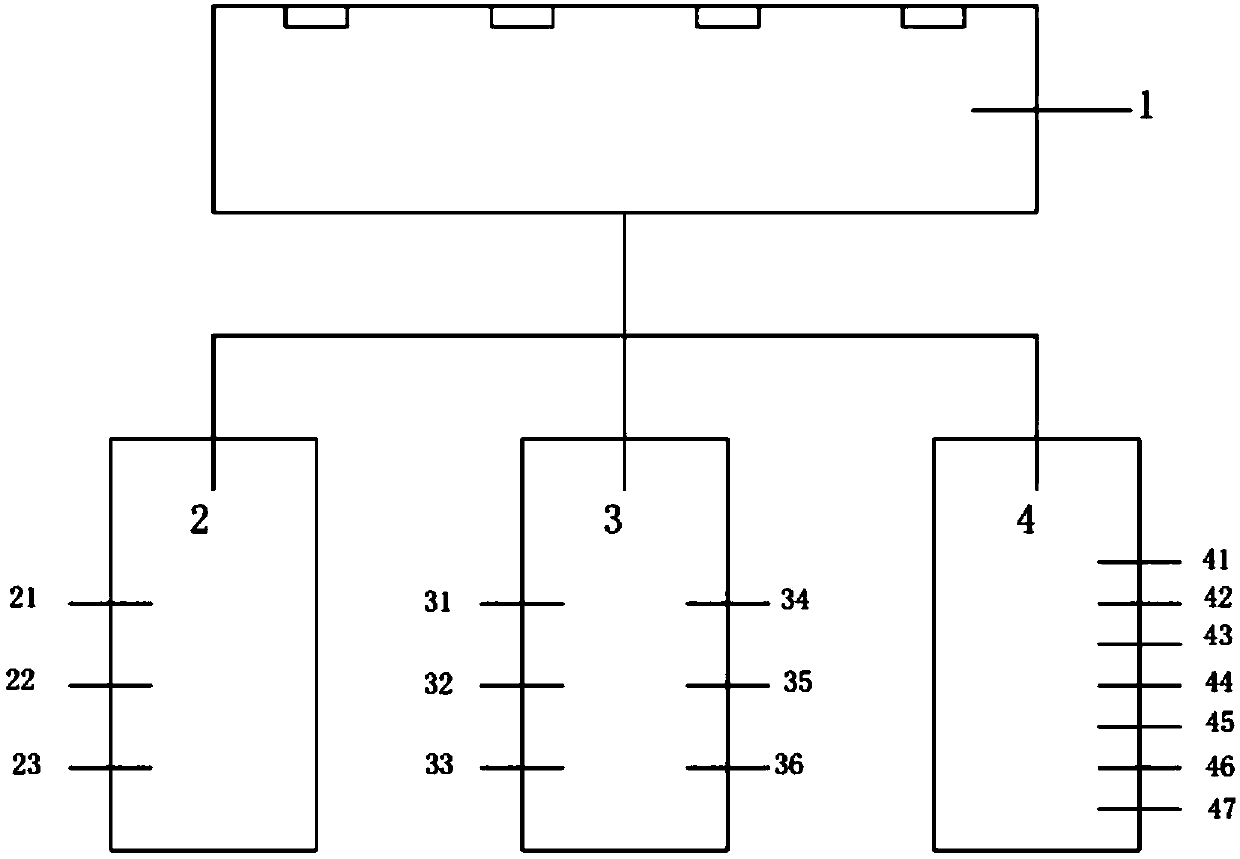

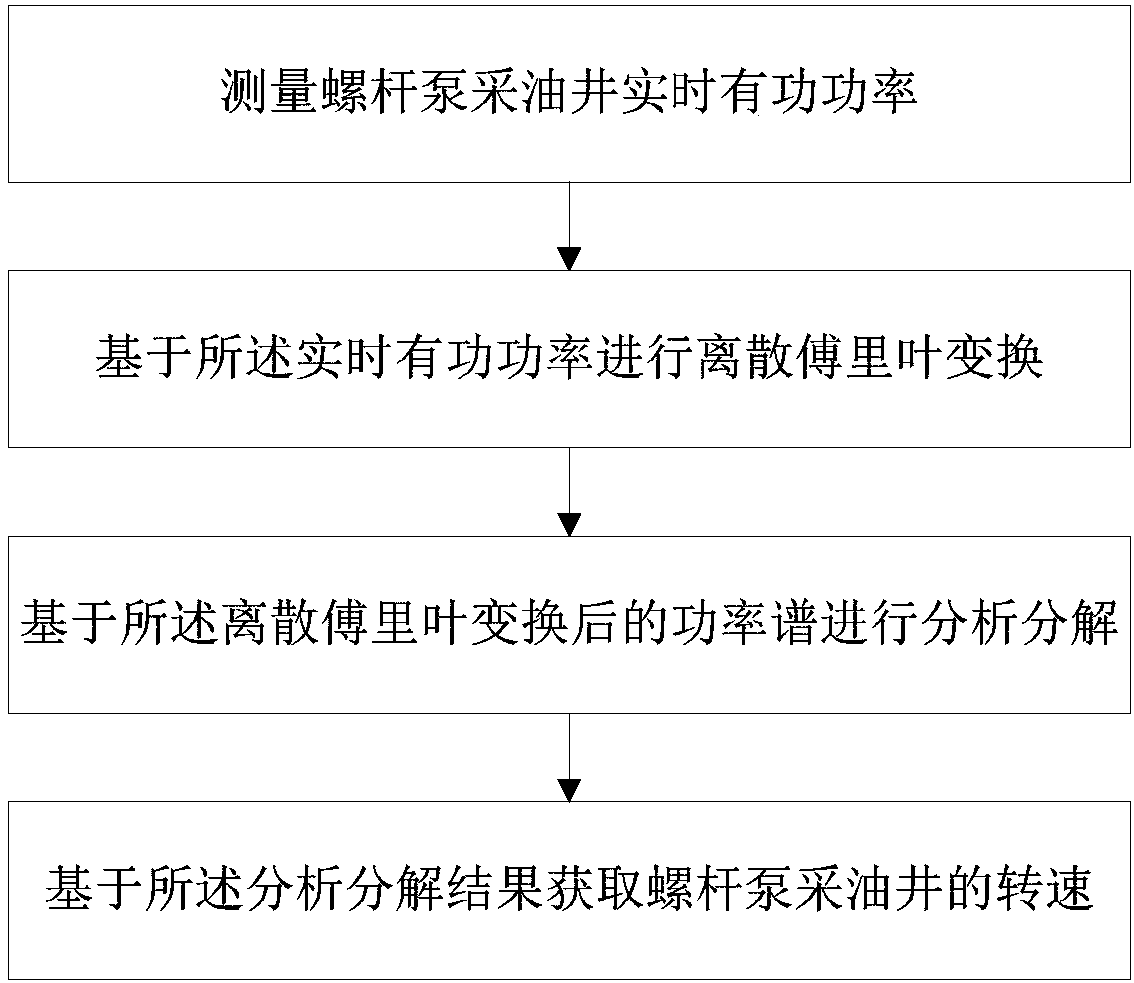

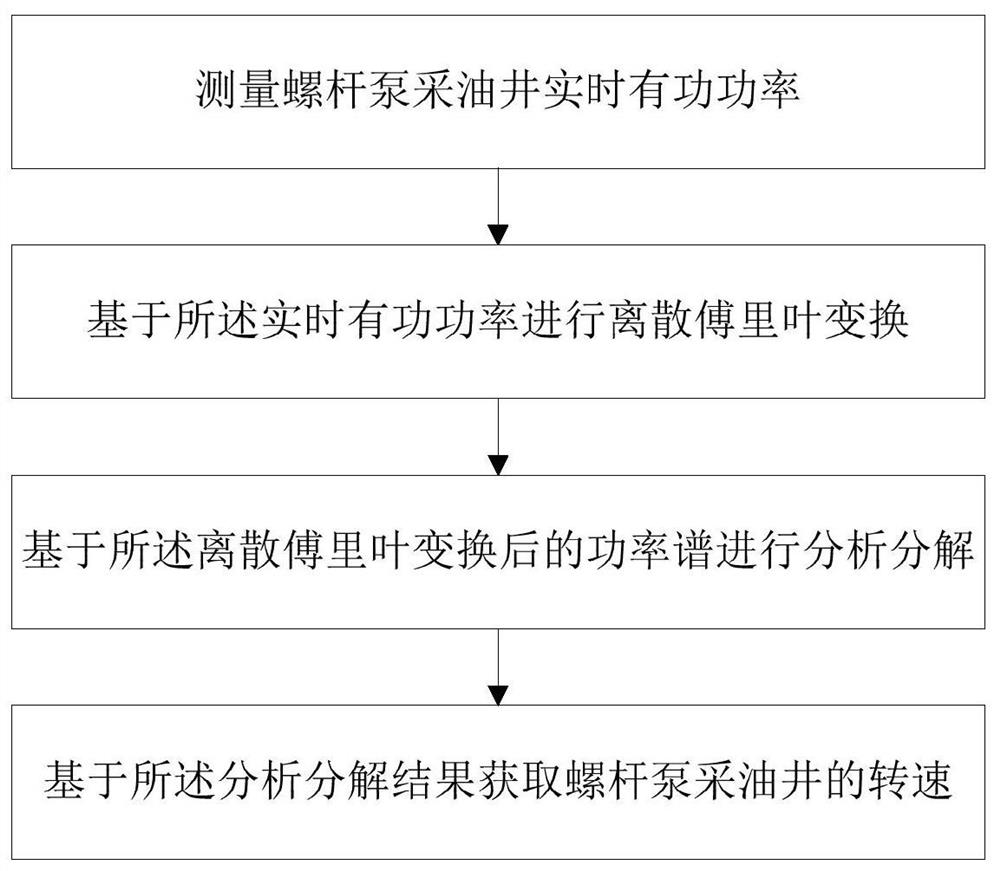

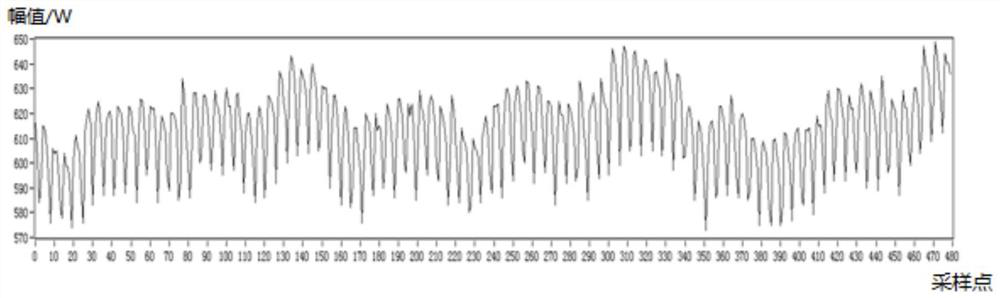

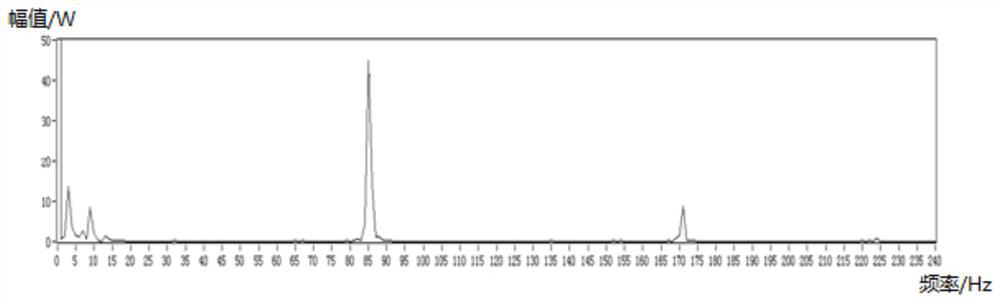

Screw pump producing well rotation speed measuring method and system

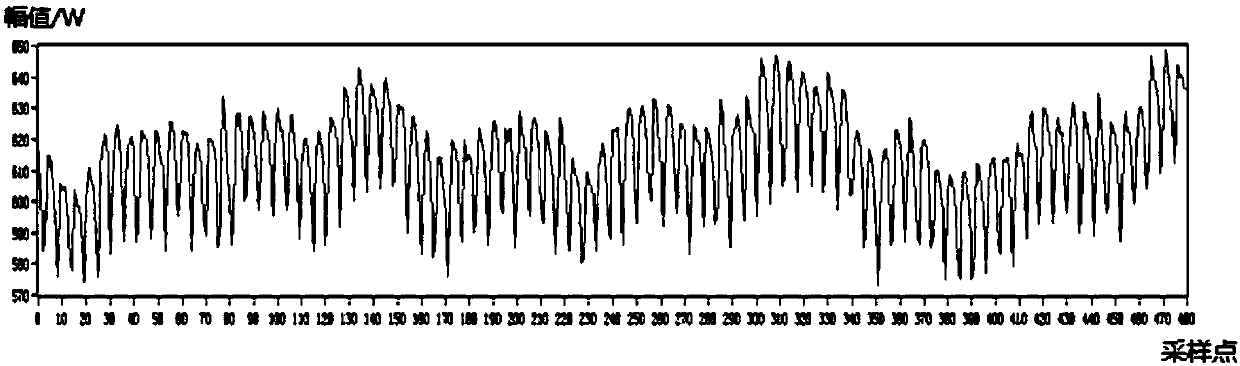

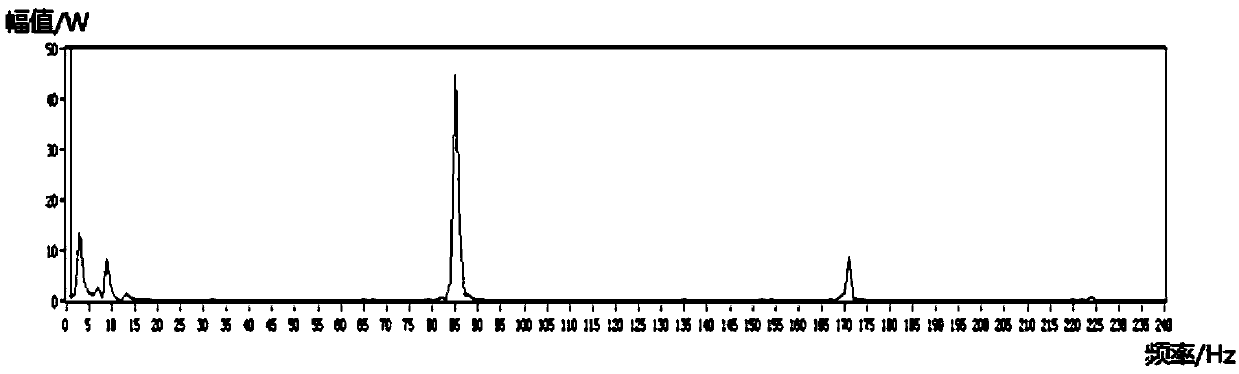

ActiveCN108798640ASimple designReal-time monitoring of speedConstructionsMachines/enginesDecompositionDiscrete Fourier transform

The invention discloses a screw pump producing well rotation speed measuring method and system. The screw pump producing well rotation speed measuring method comprises the steps that step 1, real-timeactive power of a screw pump producing well is measured; step 2, discrete Fourier transform is carried out based on the real-time active power; step 3, analysis and decomposition are carried out based on a power spectrum after the discrete Fourier transform; and step 4, the rotation speed of the screw pump producing well is obtained based on the analysis and decomposition result. The screw pump producing well rotation speed measuring method and system have the advantages that by analyzing an electric power curve of the screw pump producing well, real-time monitoring of the rotation speed of the screw pump well can be realized, and the estimation accuracy is high; monitoring of the rotation speed in real time is beneficial to designing energy saving and consumption reducing measures; and the safety is high, and installation, operation and maintenance are convenient during practical application.

Owner:CHINA PETROLEUM & CHEM CORP +1

tci igniter circuit with speed limiting function

ActiveCN106523240BSimple structureMake up for the errorMachines/enginesIgnition automatic controlIgnition coilEngineering

A TCI igniter circuit with a speed limiting function comprises an ignition control circuit and an ignition coil. The two ends of the ignition coil are connected with a flame-out line and a GND end correspondingly. The TCI igniter circuit further comprises a flame-out controller. The acquisition end of the flame-out controller is connected with the flame-out line through a speed acquisition circuit. The control end of the flame-out controller is connected with the input end of the flame-out control circuit. An output end set of the flame-out control circuit is connected with the two ends of the ignition coil correspondingly. The TCI igniter circuit with the speed limiting function is simple in overall structure; and under unified coordination of the flame-out controller, the rotating speed situation of an engine is precisely monitored in real time through a speed acquisition circuit, automatic flame-out control is achieved after the rotating speed gets ultrahigh, ignition control and speed limiting control are effectively integrated, the circuit is simplified, and the cost is lowered.

Owner:CHONGQING YUXIN PINGRUI ELECTRONICS

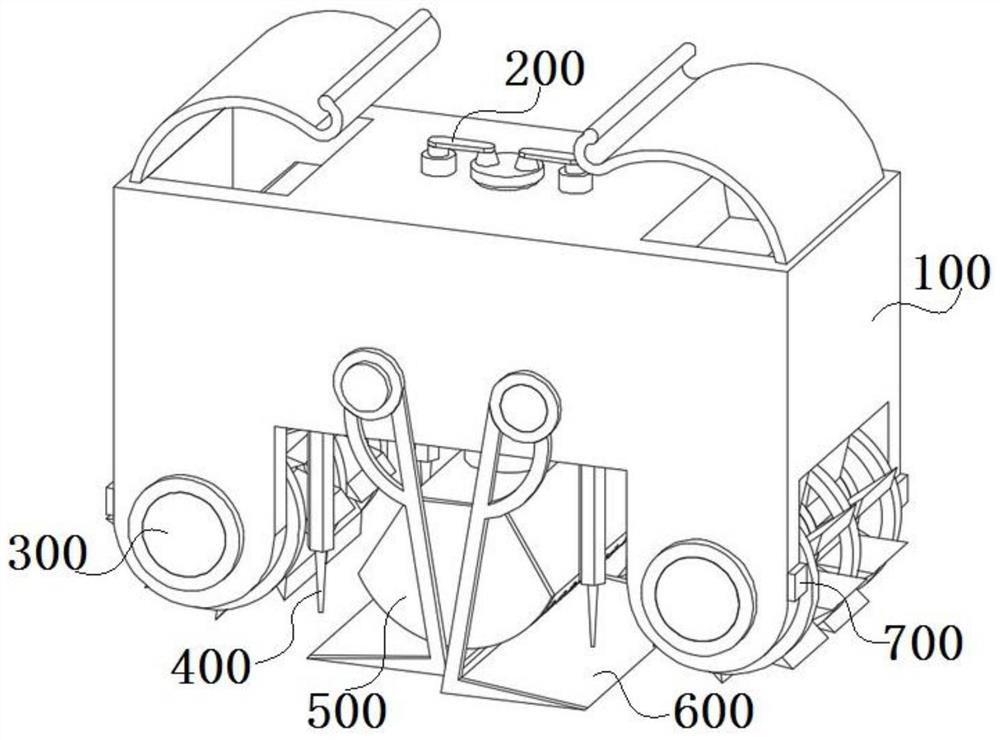

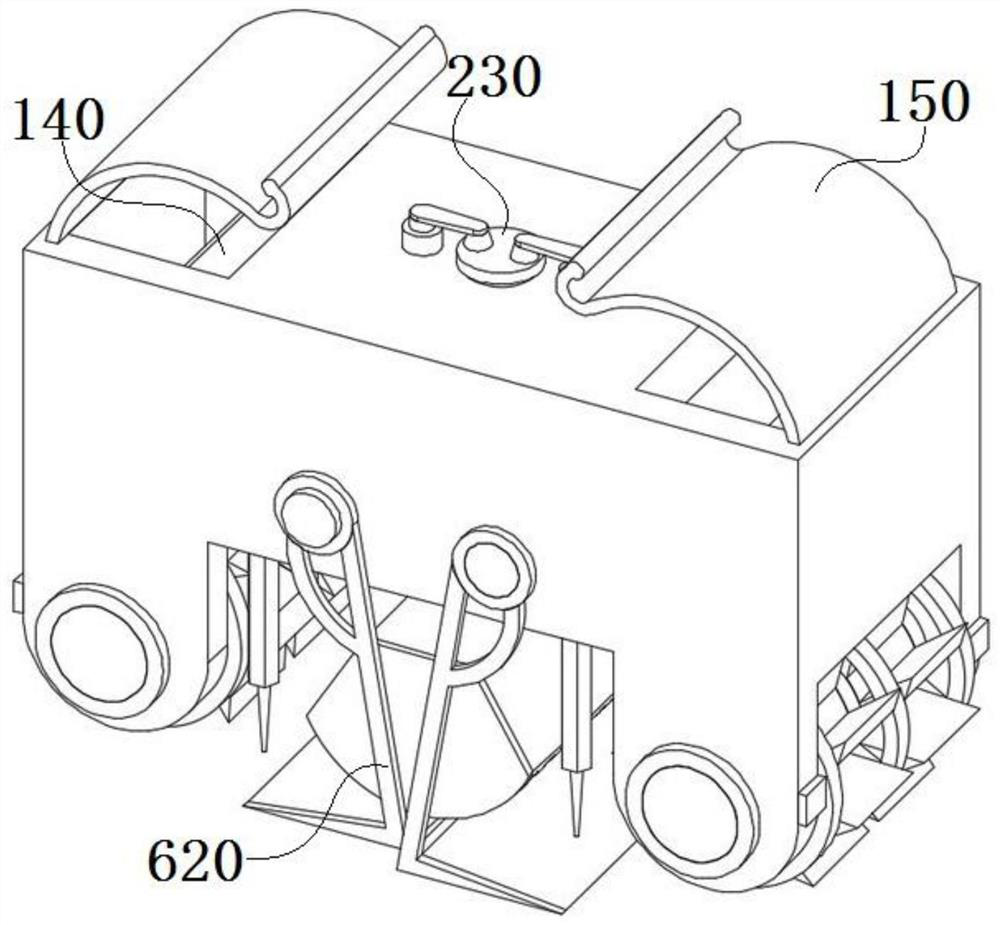

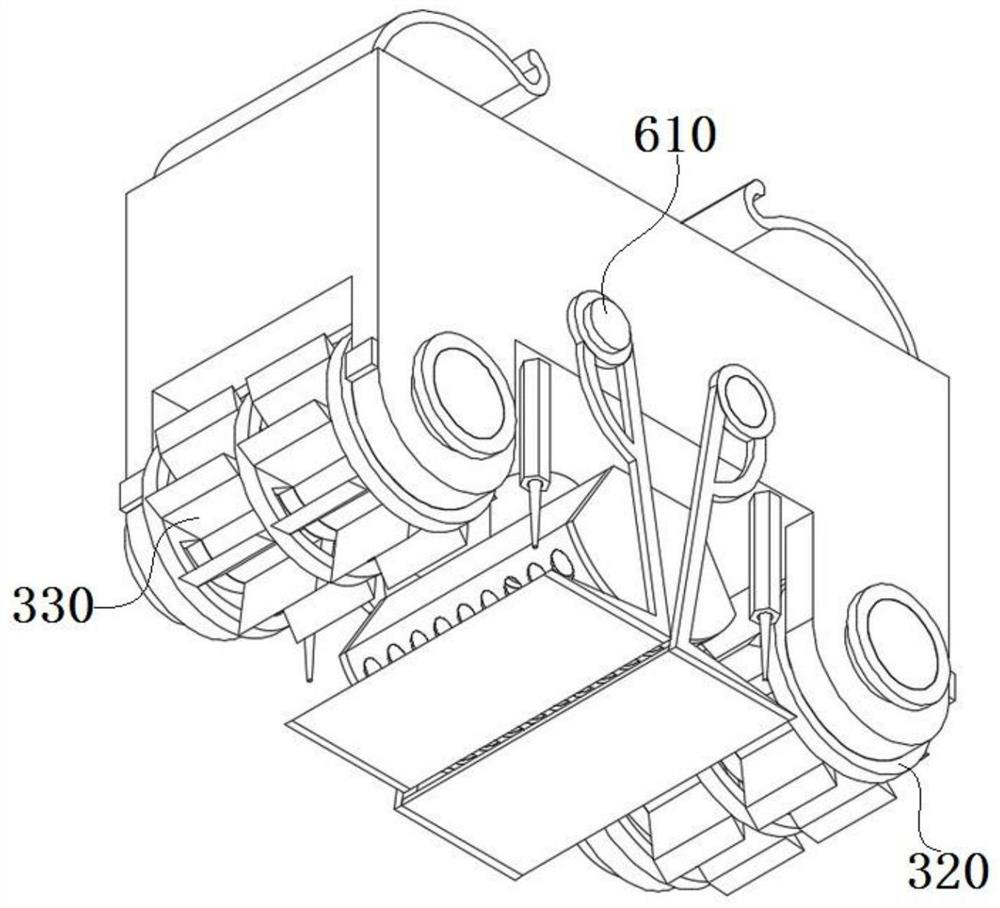

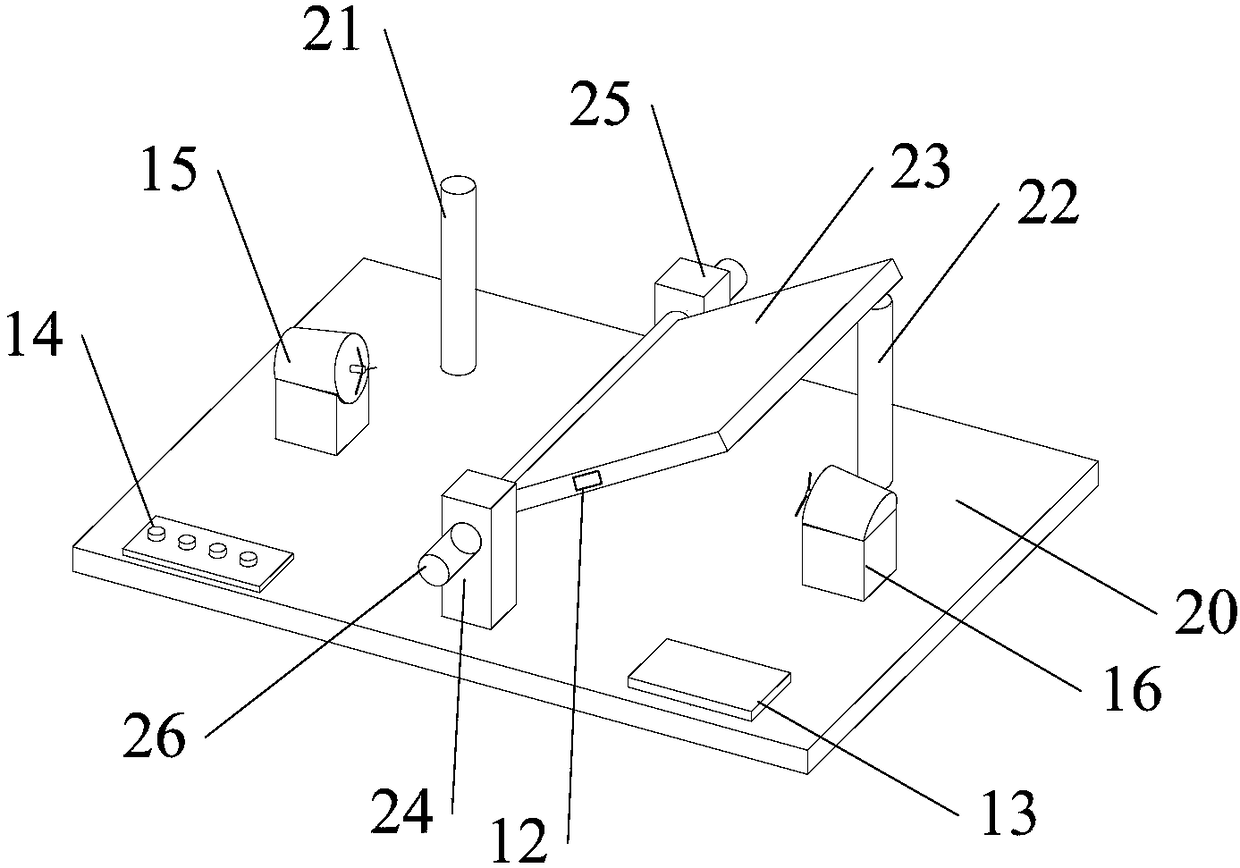

Farmland heavy metal restoration treatment equipment

InactiveCN113000581AReal-time monitoring of speedImprove ride comfort performanceContaminated soil reclamationTilling equipmentsLiquid storage tankSoil heavy metals

The invention discloses farmland heavy metal restoration treatment equipment which comprises a main body, an agent storage device, an advancing device, a detection device, a spraying device, a mixing device and a sensing device, the detection device is connected with the main body through a lifting hexagonal prism, the advancing device is connected with the main body through a bidirectional rotating shaft, and the spraying device is connected with the agent storage device through a liquid guide pipe; the agent storage device is connected with the main body through a repair liquid storage tank, the mixing device is connected with the main body through an oscillation rotating shaft, and the sensing device is connected with the advancing device through a rotating speed detector. Soil scarification is achieved through the soil scarification flywheel knife, soil with different hardness is scarified by adjusting different rotating speeds, energy is saved, the surrounding environment of the vehicle body is detected through the detector, the detection cone moves downwards through the lifting hexagonal prism, the content and variety of heavy metal in the soil are detected through the detection cone, and remediation liquid is stored through the remediation liquid storage box. Remediation liquid is guided in through the liquid guide pipe, and the remediation liquid is sprayed into the soil through the fan-shaped spraying box.

Owner:HENAN UNIVERSITY

Wind plate control device and method

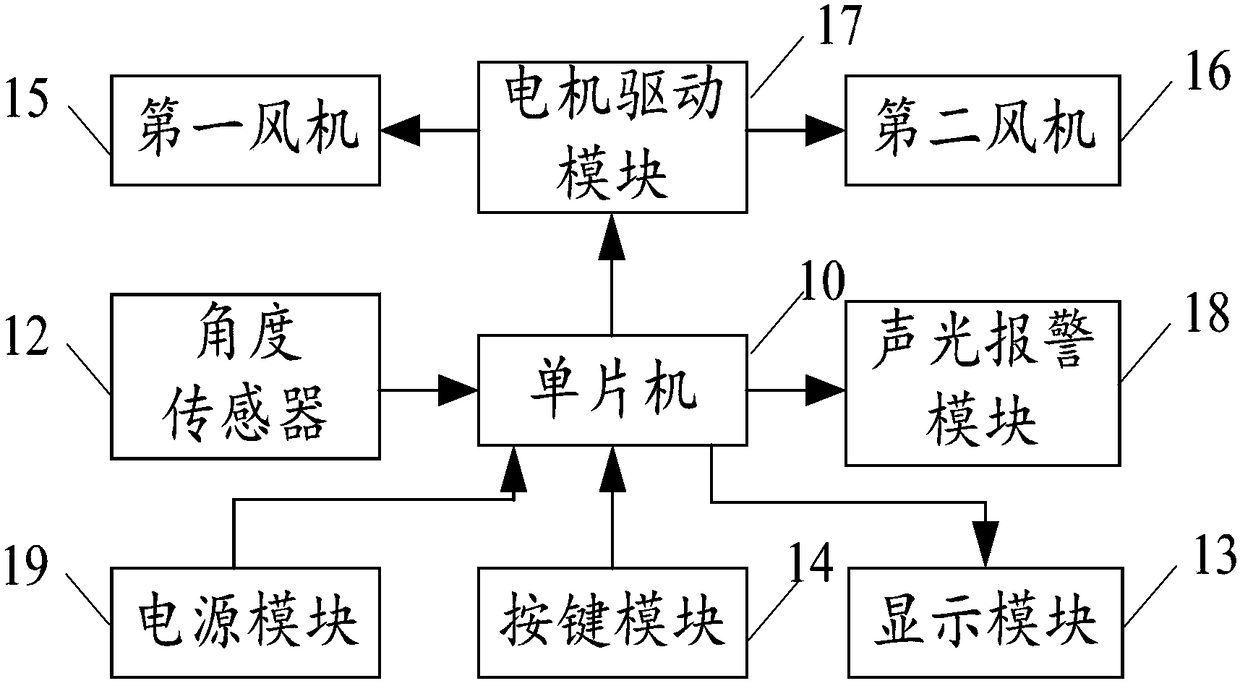

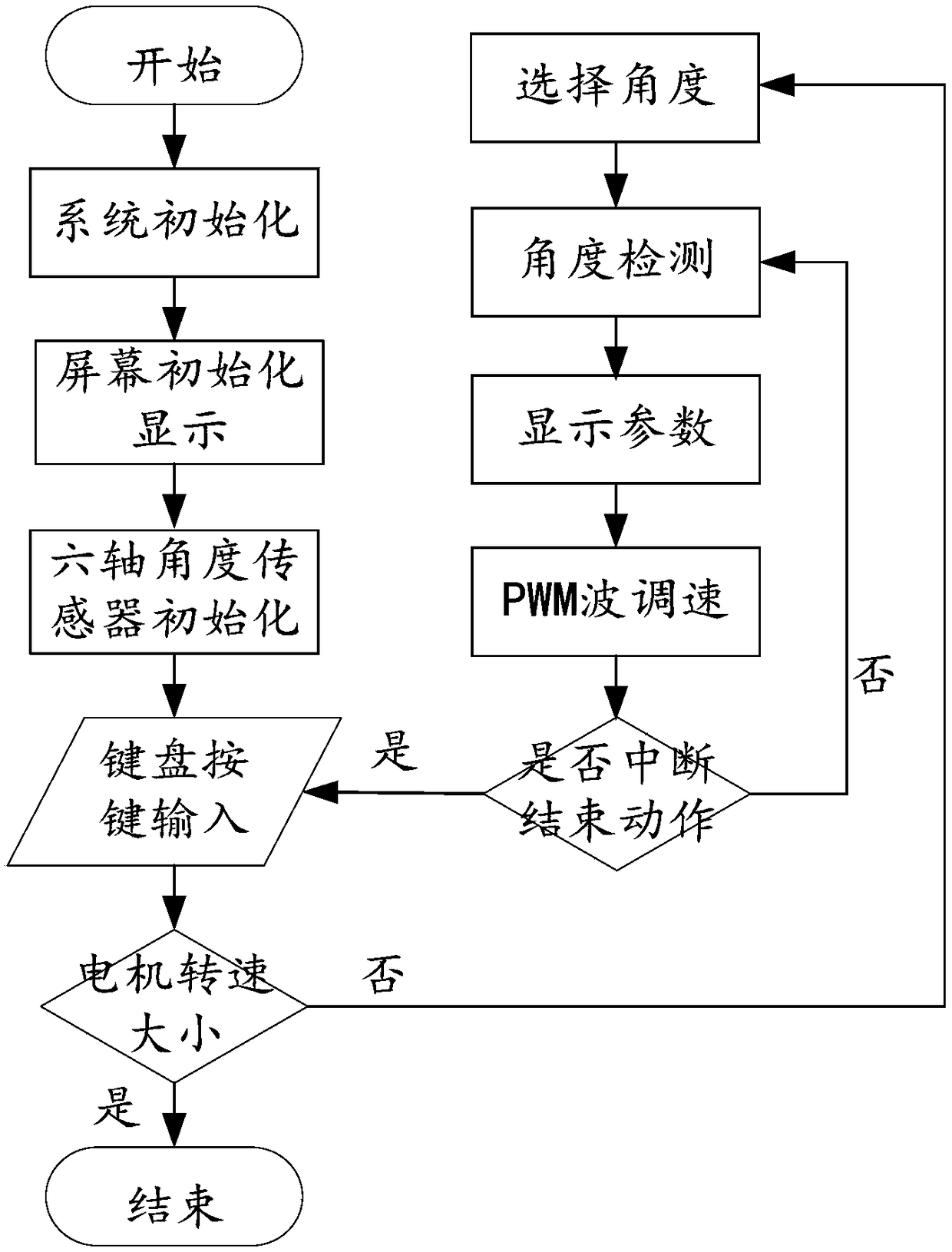

PendingCN108154785AReal-time monitoring of speedImprove accuracyEducational modelsMicrocontrollerMicrocomputer

The invention provides a wind plate control device. The device comprises a base, a wind plate, an angle sensor, a single chip microcomputer, a key module, a display module and a power module. The angle sensor is arranged on the wind plate, and a first fan and a second fan are arranged on the base; the angle sensor is used for detecting the swing angle of the wind plate between the first fan and the second fan and transmitting a detected swing angle signal to the single chip microcomputer; the single chip microcomputer is used for receiving and processing the signal of the swing angle which isdetected by the angle sensor, transmitting a processing result to the display module and controlling the rotation speed of the first fan and the second fan; the key module is used for triggering the single chip microcomputer to adjust the rotation speed of the first fan and the second fan; the display module is used for displaying the swing angle of the wind plate; the power module is used for providing power for the single chip microcomputer. According to the wind plate control device, the accuracy of adjusting the inclined angle of the wind plate can be effectively improved, and the experiment efficiency is improved. The invention further provides a wind plate control method.

Owner:GUANGZHOU COLLEGE OF SOUTH CHINA UNIV OF TECH

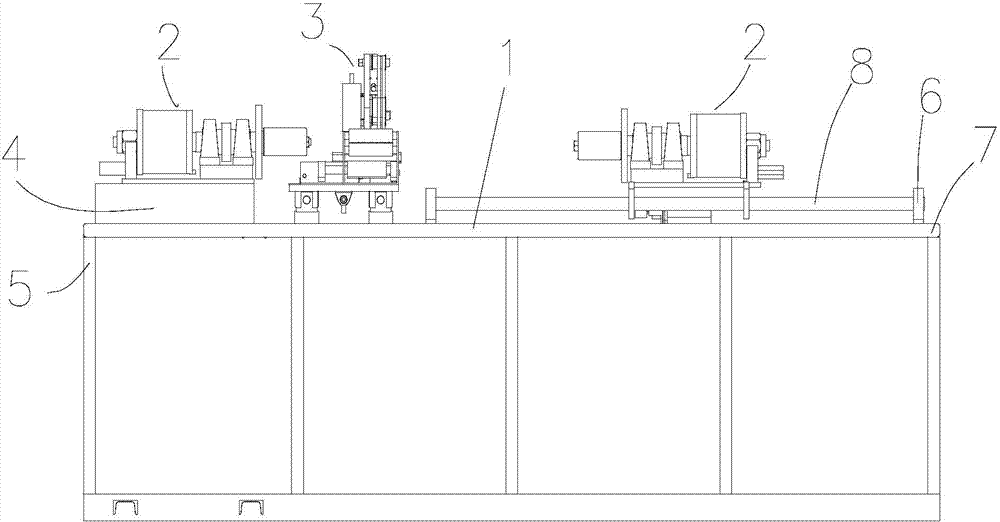

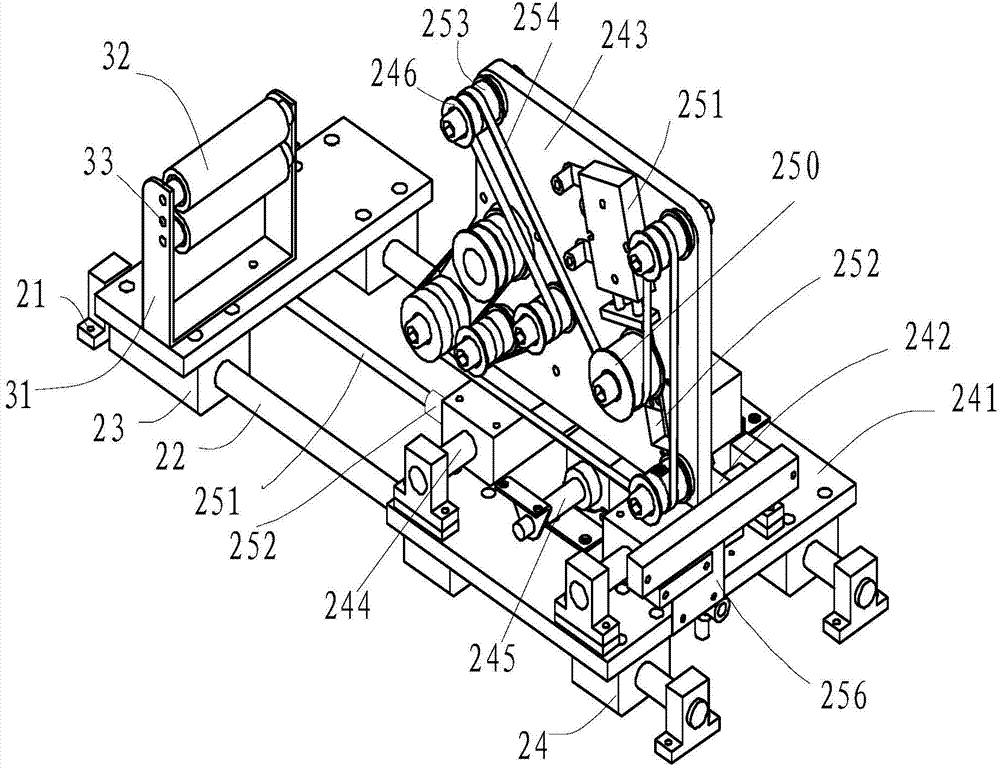

Fire hose testing machine

ActiveCN103487344BReduce work intensityImprove test reliabilityMaterial strength using tensile/compressive forcesInvestigating machinabilityElectricitySynchronous motor

Owner:济南康和消防技术有限公司

Electric underwater aircraft navigation speed measurement method and device based on Doppler effect

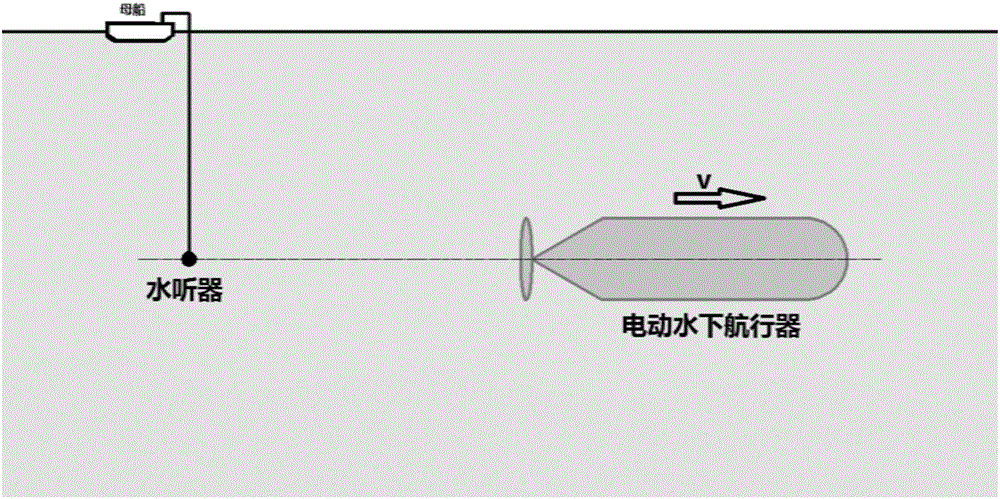

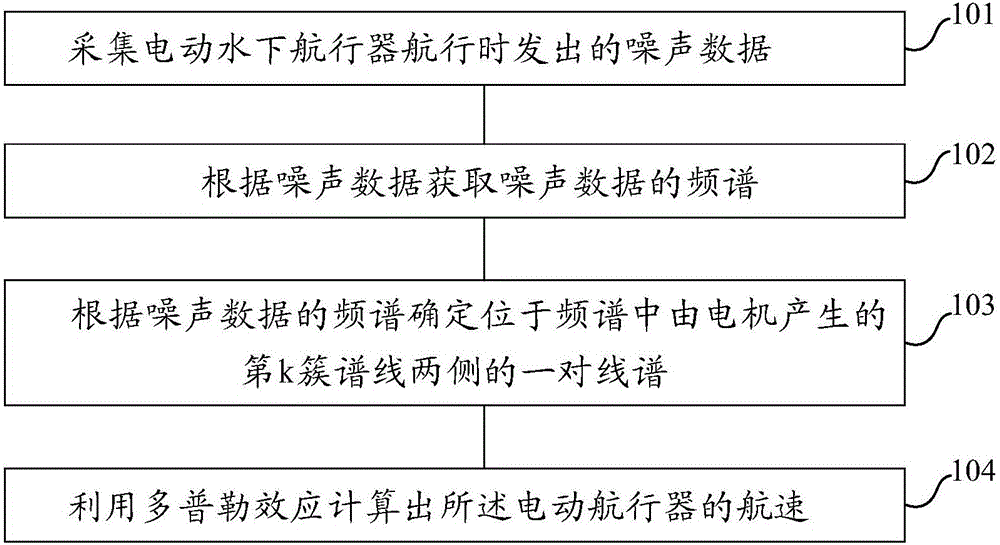

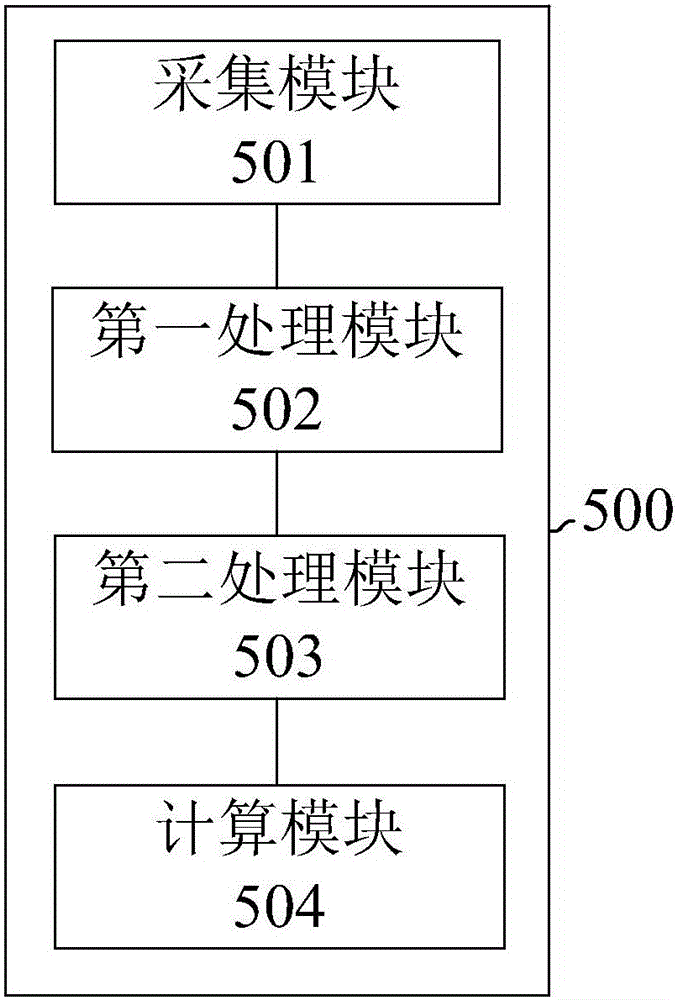

The invention discloses an electric underwater aircraft navigation speed measurement method and device based on the Doppler effect.The method includes the steps that noise data generated when an electric underwater aircraft sails are collected; the frequency spectrum of noise data is obtained according to the noise data; a pair of line spectrums on the two sides of the center of the kth-cluster spectral line generated by a motor located in the frequency spectrum is determined according to the noise data; the navigation speed of the underwater aircraft is calculated through the Doppler effect with frequency shift which is k frequency doubling relative to inverter switching frequency.The device comprises an acquisition module, a first processing module, a second processing module and a calculation module.According to the electric underwater aircraft navigation speed measurement method and device based on the Doppler effect, the structure is simple, the motor noise feature that a frequency converter is utilized to supply power is reasonably utilized, and the navigation speed of the electric underwater aircraft is monitored in real time externally.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

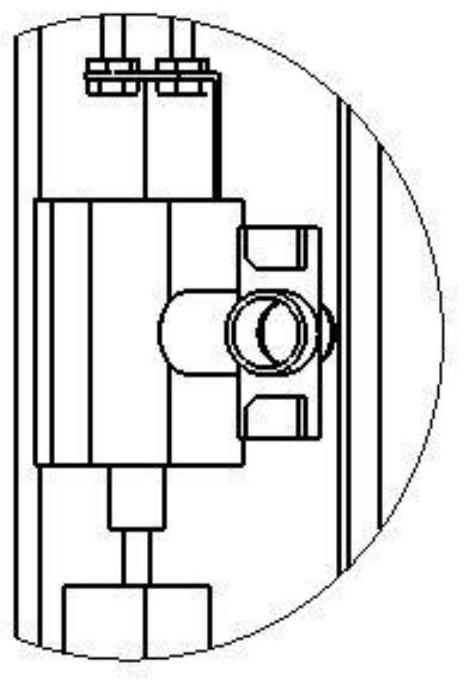

Measurement device capable of calibrating corner signal and three-dimensional vibration of crankshaft

InactiveCN101581623BAchieve fixationRealize OKInternal-combustion engine testingVibration testingMeasurement deviceBall bearing

The invention discloses a crankshaft three-dimensional vibration measurement device capable of calibrating a crankshaft corner signal. A photoelectric encoder is fixed in the center hole of a stop block by a bolt, and the stop block is also fastened on the end face of a casing by the bolt. A pair of ball bearings is arranged between the casing and a transmission shaft, and the exterior ends of theball bearings are fixed on the casing by a fastener bolt and a fastening check ring. The exterior end of the stop block is provided with a three-dimensional vibration sensor. The photoelectric encoder is connected with the transmission shaft by a connecting shaft to rotate synchronously and outputs two voltage signals which are respectively used for carrying out the torsional vibration analysis and the top dead centre calibration of a crankshaft. In the invention, bending vibration under different corners of the crankshaft can be decomposed, and synthesis is carried out on the rotating coordinate system of the crankshaft at a position corresponding to the corner of the crankshaft, so that the measurement of the rotating coordinate system of the crankshaft can be realized, bending vibration consistent to the rotating coordinates of the crankshaft is obtained by software calculation, and real-time monitoring can be carried out on an engine in terms of the revolution speed and the revolution number.

Owner:TIANJIN UNIV

Motor rotating speed monitoring device

InactiveCN106199037AReal-time monitoring of speedThe monitoring results are accurateDevices using optical meansCapacitanceEngineering

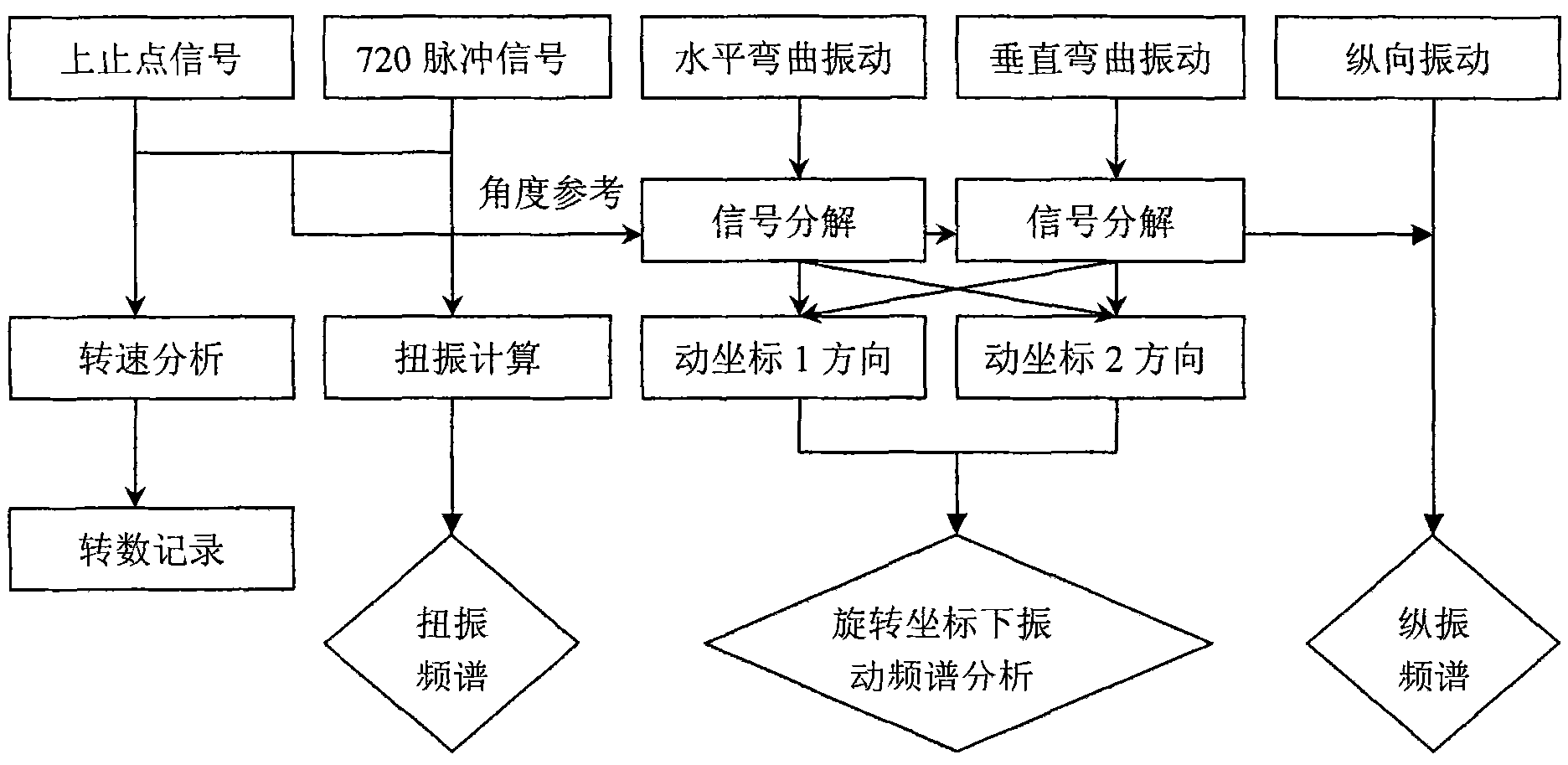

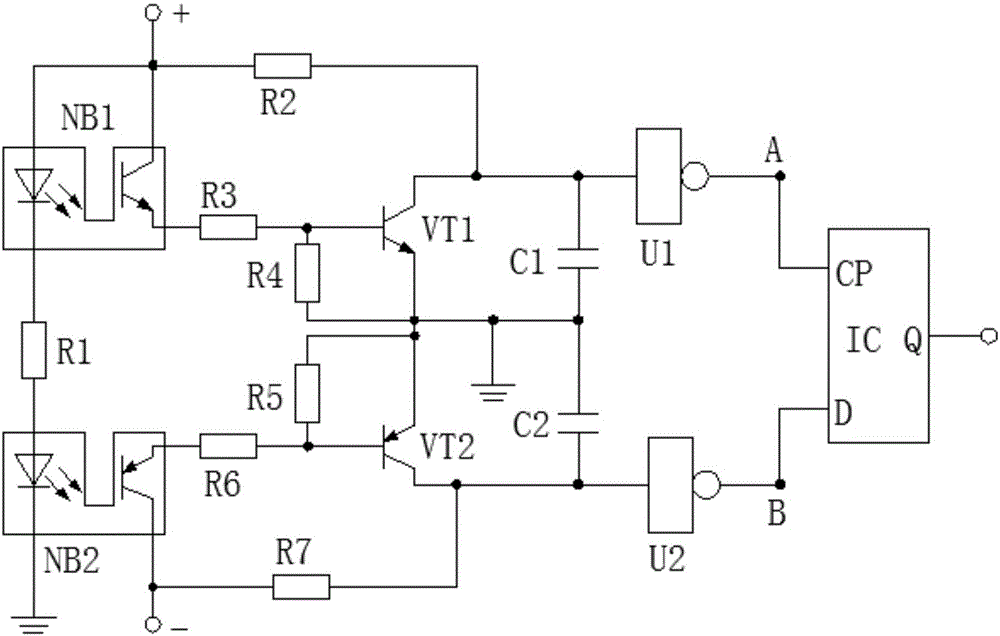

The invention discloses a motor rotating speed monitoring device which is composed of a first optical coupler, a second optical coupler, first to seventh resistors, a first capacitor, a second capacitor, a first triode, a second triode, a first NOT gate, a second NOT gate and a double-D-trigger. The first resistor is 100ohm. The second resistor is 400ohm. The third resistor is 500ohm. The fourth resistor is 2kilohm. The fifth resistor is 27kilohm. The sixth resistor and the seventh resistor are 200ohm. The first capacitor is 300muf. The second capacitor is 470muf. The first triode is a PNP type triode. The second triode is an NPN type triode. The first NOT gate and the second NOT gate are the NOT gates of the model number of SN74HC1G04. The model number of the double-D-trigger is MCR100-6 / 0.8A / 400V. Compared with the devices in the prior art, rotating speed of a motor can be monitored in real time, and the optical couplers are used for sensing and the NOT gate circuits are used for control so that the monitoring result is accurate, use is convenient, and the device has popularization and application value.

Owner:HUNAN INSTITUTE OF ENGINEERING

Fertilizer box remaining amount monitoring system and monitoring method

PendingCN112162298AFitting graphic error is smallMargin detection linearity is highFertiliser distributersMachines/enginesFertilizerAgricultural engineering

The invention relates to a fertilizer box remaining amount monitoring system and monitoring method. The fertilizer box remaining amount monitoring system comprises a fertilizer applicator, WHEREIN thefertilizer applicator comprises a fertilizer box, a fertilizer discharging mechanism, a cab, an electric control system and main control equipment, wherein the electric control system comprises a laser distance measuring sensor array used for monitoring the information of the distance between the fertilizer in the fertilizer box and the inner side of the top part of the fertilizer box in real time and sending the information to a controller, an opening degree detection sensor used for detecting an opening degree of a fertilizer discharging shaft in the fertilizer discharging mechanism and sending the opening degree to the controller, a rotating speed detection sensor used for detecting a rotating speed of the fertilizer discharging shaft in the fertilizer discharging mechanism and sendingthe rotating speed to the controller, the controller used for processing all the received information and sending the information to the main control equipment, and a 5 V power supply used for supplying power to each sensor and the controller; and the main control equipment is used for calculating the remaining amount of the fertilizer box, predicting the fertilization duration and giving emptying early warning. The fertilizer box remaining amount monitoring system and the monitoring method can be widely applied to the field of fertilizer box remaining amount monitoring.

Owner:CHINA AGRI UNIV

Double-turbine direct-driven permanent magnet synchronous generator set

PendingCN113374661AReduce friction lossImprove robustnessCombination enginesSafety/regulatory devicesCold airControl system

The invention relates to the technical field of centripetal turbine low-grade heat energy power generation, in particular to a double-turbine direct-driven permanent magnet synchronous generator set. The double-turbine direct-driven permanent magnet synchronous generator set comprises a permanent magnet synchronous generator, a control system and centripetal turbines, wherein a cooling system is arranged on a shell of the permanent magnet synchronous generator; the cooling system comprises a cold water system arranged on the outer side of the shell and a cold air system communicating with the interior of the shell; the control system is used for controlling the displacement state of a rotating shaft of the permanent magnet synchronous generator; the two centripetal turbines are symmetrically arranged at the two ends of the permanent magnet synchronous generator; and a first communicating pipe is connected to an inlet of each centripetal turbine, and a second communicating pipe is connected to an outlet of each centripetal turbine. The double-turbine direct-driven permanent magnet synchronous generator set can effectively offset axial force borne by the generator set, the generator set is free of friction loss and high in motion precision in the operation process, the size of the generator set can be reduced by adopting a direct drive mode, cost is saved, and power generation efficiency is improved.

Owner:SHANDONG UNIV

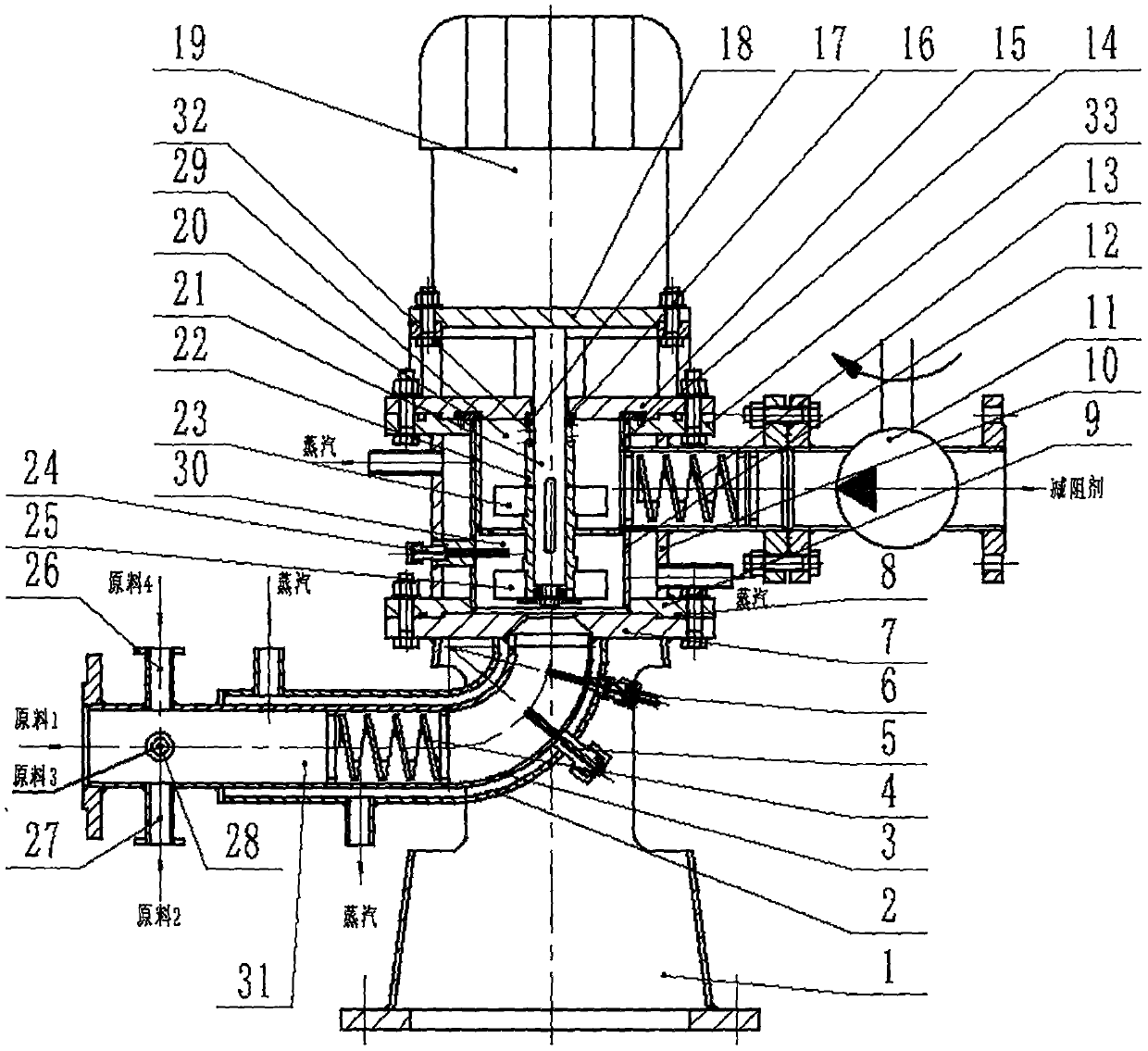

Device for preparing emulsion matrix conveying drag reducer

PendingCN111389294AUniform densityGuaranteed process temperature requirementsTransportation and packagingMixersExplosive AgentsElectric machine

The invention discloses a device for preparing an emulsion matrix conveying drag reducer, and relates to the field of bulk emulsion explosive production equipment. The device mainly comprises a base,a feeding channel, a static mixer, a temperature sensor, a pressure sensor, a stirring barrel, a flow pump, a secondary stirring barrel, a connected base, a mechanical seal, a motor, a stirring device, a rotating speed sensor, a feeding hole, a mixing cavity and a vibration absorber. According to the device for preparing the emulsion matrix conveying drag reducer, the process temperature, pressureand rotating speed during drag reducer production can be guaranteed, and the produced drag reducer is uniform in phase formation, stable in quality, simple in structure, convenient to operate and maintain and low in maintenance cost.

Owner:湖南金石智造科技有限公司

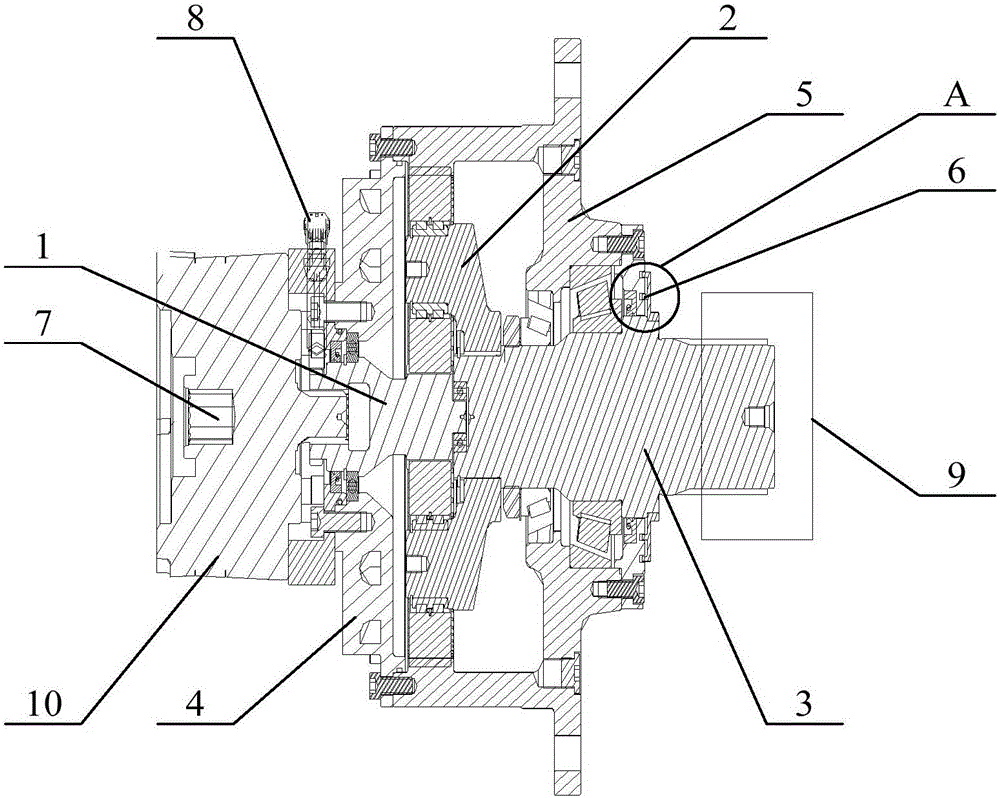

A magnetic stirring device and stirring and mixing equipment

ActiveCN111992116BHigh strengthThe stirring process is stable and reliableNuclear energy generationTransportation and packagingEngineeringMechanical engineering

The invention discloses a magnetic stirring device, comprising an upper stirring shaft assembly, a lower stirring shaft assembly and a magnetic coupling, the upper stirring shaft assembly includes an upper stirring shaft, the lower stirring shaft assembly includes a lower stirring shaft, the The upper stirring shaft is connected with the lower stirring shaft through the magnetic coupling. The invention also discloses a stirring and mixing device comprising the above-mentioned magnetic stirring device. The magnetic stirring device of the invention can realize long-distance power transmission, and is stable and reliable.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Server fan speed control system and method

ActiveCN108953205BIncrease duty cycleMonitor temperature in real timeDigital data processing detailsHardware monitoringComputer hardwareControl system

The invention discloses a server fan speed control system and method. The server fan speed control system comprises a BMC, an SAS card connected with the BMC, a back board connected with the SAS card,a CPLD mounted on the back board, and hard disks connected with the back board; a PBSI module is arranged in the SAS card; the BMC is connected with the SAS card and the CPLD through I2C buses; the SAS card is connected with the back board through an SAS wire cable; and the hard disks are connected with the back board through an SATA or SAS interface. Compared with the prior art, the temperaturesof the hard disks can be monitored accurately in real time to adjust a fan speed.

Owner:SHENZHEN TONGTAIYI INFORMATION TECH CO LTD

Roller bit with temperature monitoring and cooling functions

PendingCN113818812AWith monitoring functionWith cooling functionDrill bitsAutomatic control for drillingControl systemEngineering

The invention provides a roller bit with temperature monitoring and cooling functions, and belongs to the technical field of roller bits. The roller bit comprises a bit body, a temperature sensor, a rotating speed sensor, a cooling mechanism and a control system, wherein the bit body is provided with a cavity, a cooling channel is arranged in the bit body, the temperature sensor and the rotating speed sensor are used for monitoring the temperature and the rotating speed of the cone in real time, the cooling mechanism is arranged in the cooling channel and provided with a water spraying assembly which can move in the cooling channel in the height direction of the drill bit body and can stretch out of the upper end of the cooling channel, and the water spraying assembly is used for spraying a cooling liquid to the cone to reduce the temperature of the cone. The control system is arranged in the cavity and used for receiving temperature and rotating speed information and controlling the cooling mechanism to operate. The device has the technical effects that the real-time working temperature and the rotating speed of the roller bit can be monitored in real time in the drilling process of the roller bit, the drill bit is cooled in time, the working state is monitored in time, information is fed back in time, the drill bit is reasonably used, and the service life of the drill bit is prolonged.

Owner:CANGZHOU GREAT DRILL

Intelligent fuel gas shaping machine

InactiveCN106359671AGuaranteed shape effectReal-time monitoring of speedPre-extraction tea treatmentFrequency changerAutomatic control

The invention relates to an intelligent fuel gas shaping machine. According to the intelligent fuel gas shaping machine, the heating temperature of a roller is controlled by virtue of an air intake regulating valve, the dehumidification speed is controlled by virtue of a dehumidification motor, and the rotation speed of the roller is controlled by virtue of a frequency converter of a driving mechanism; tea shaping process is divided to be realized by a preheating control module, a feeding control module, a process section control module and a discharging control module. According to a computer program established after multiple experiments, and the input process name, one-key automatic operation is realized, and operation of the intelligent fuel gas shaping machine can be finished, and the intelligent fuel gas shaping machine is intelligent, convenient and efficient. In a similar way, the process section can be automatically controlled by multiple time sequence units, so that the shaping effect can be better ensured; in addition, the intelligent fuel gas shaping machine can be provided with a thermocouple, a humidity test instrument and a speed-measurement sensor so as to monitor various process parameters in real time and automatically regulate the process parameters through a control system; a technologist can perform manual setting and regulation according to actual process demands. The intelligent fuel gas shaping machine is especially suitable for shaping operation of high-grade, brand-name and high quality green tea and can be popularized and applied in automatic production line establishment.

Owner:SICHUAN NAT TEST MEASURING INSTR TECH

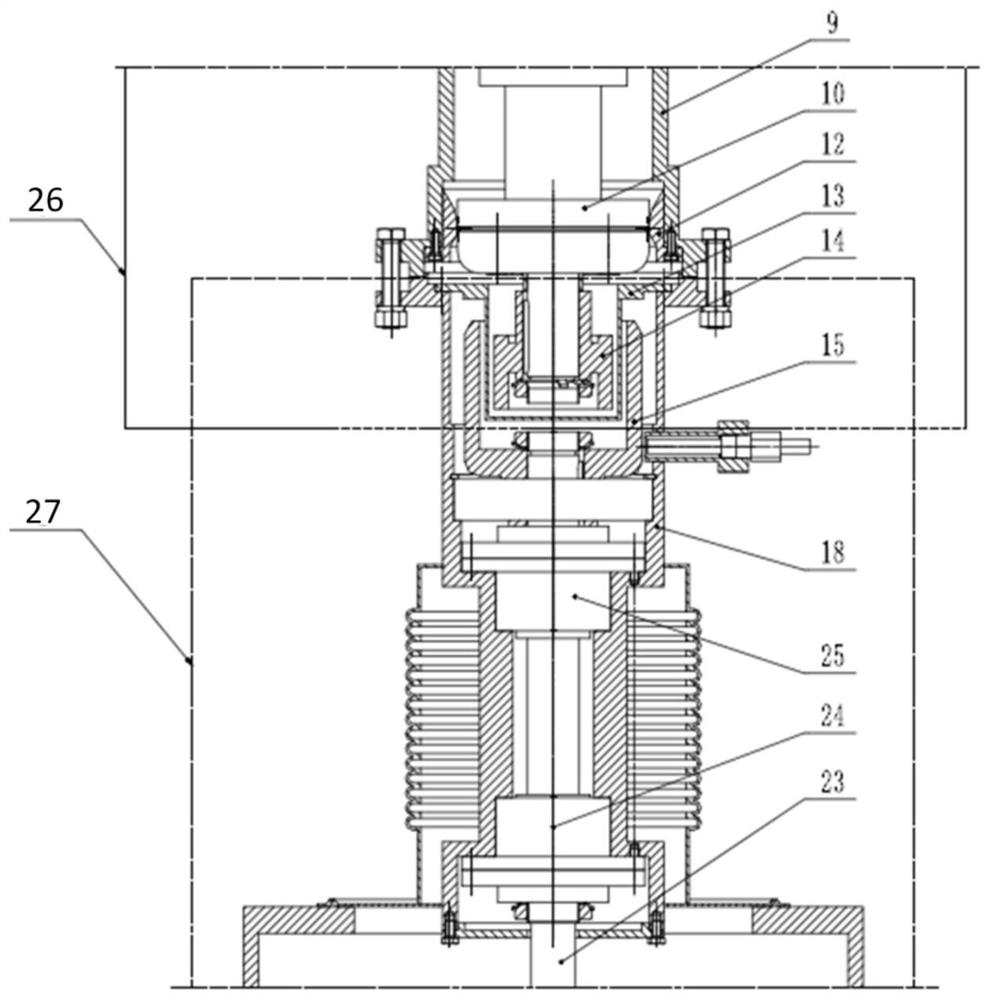

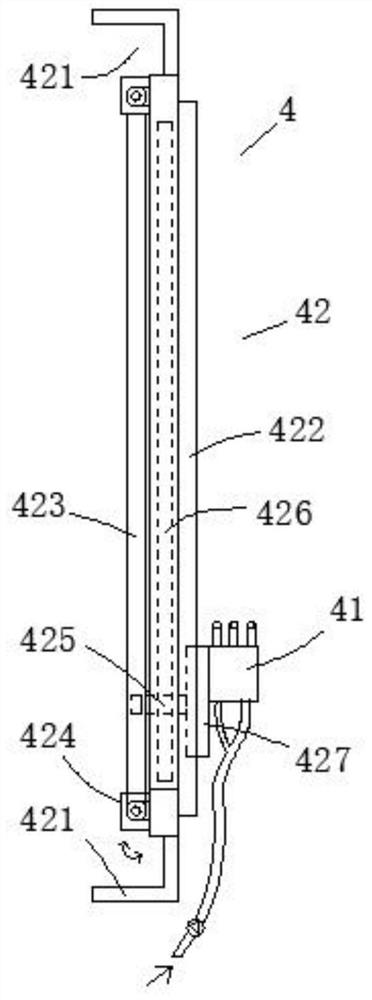

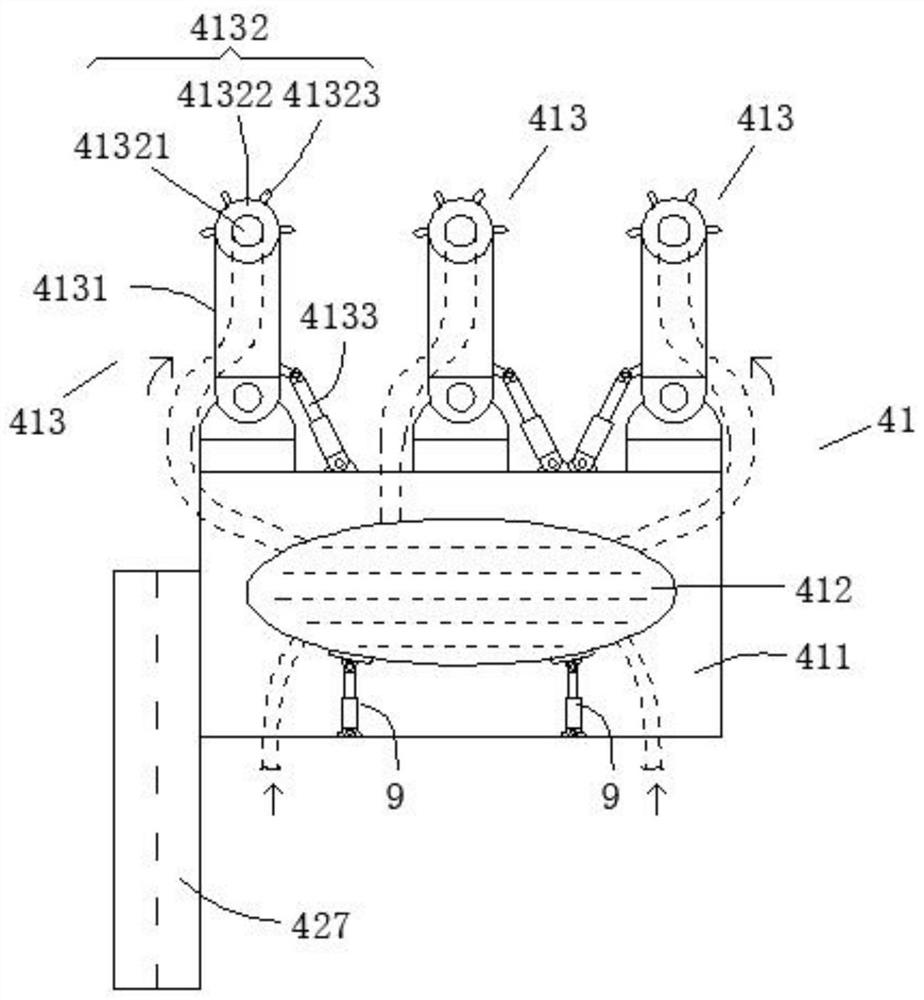

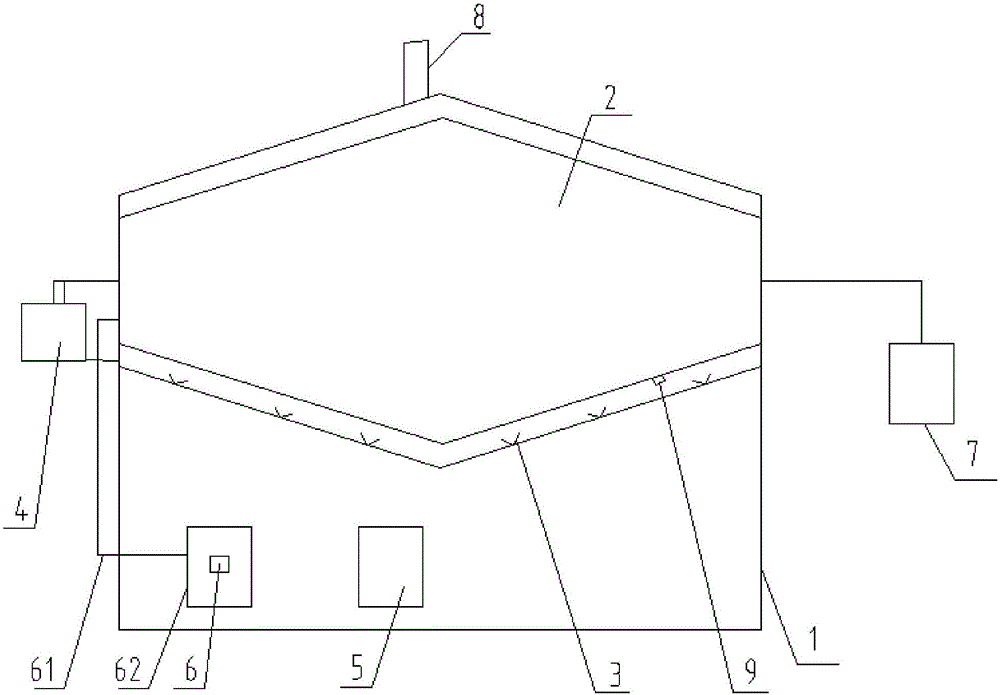

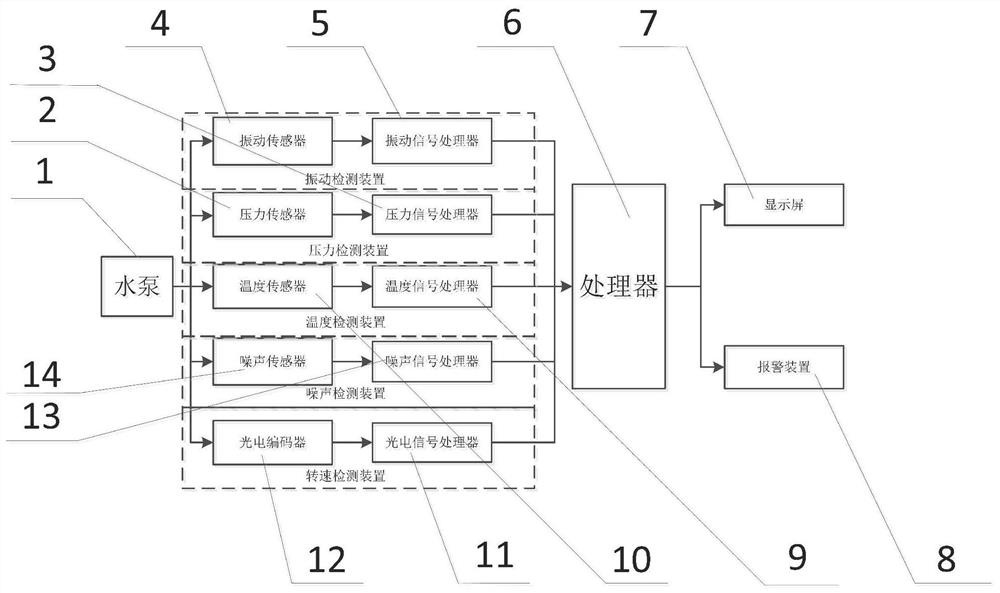

Monitoring device for service performance of water pump

InactiveCN111622939AAchieve vibrationReal-time monitoring of speedPump testingMeasurement devicesEngineeringHydrology

The invention discloses a monitoring device for service performance of a water pump. The monitoring device is technically characterized by comprising the water pump, a vibration sensor, a vibration signal processor, a pressure sensor, a pressure signal processor, a temperature sensor, a temperature signal processor, a noise sensor, a noise signal processor, an optical-electric encoder, an optical-electric signal processor, a processor, a display screen and an alarm device. The vibration sensor, the pressure sensor, the temperature sensor, the noise sensor and the optical-electric encoder are adopted for monitoring the vibration, pressure, temperature, noise and rotating speed of the water pump in real time. The optical-electric encoder is adopted as the core of a rotating speed detection device, and the rotating speed of the water pump can be monitored in real time rapidly and accurately. The display screen and the processor are connected, and therefore the service performance of the water pump can be monitored in real time. The alarm device and the processor are connected, and an alarm can be given when water pump data are abnormal.

Owner:NORTHWEST A & F UNIV

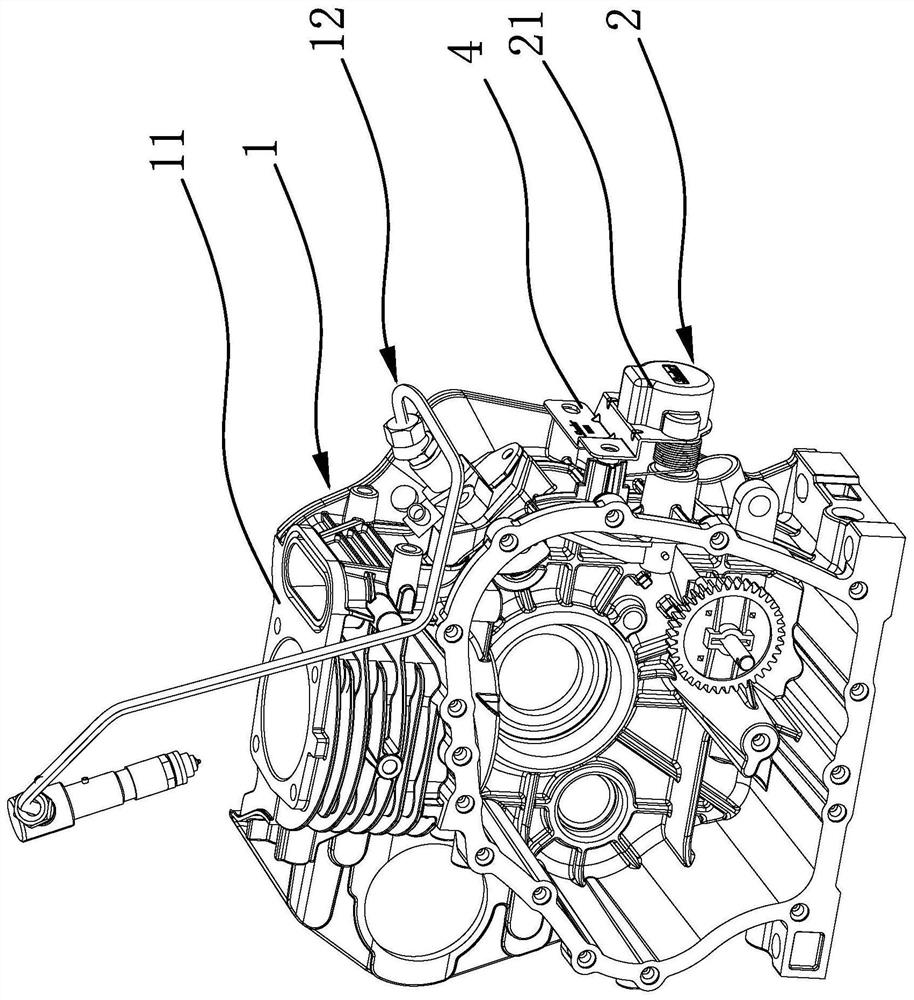

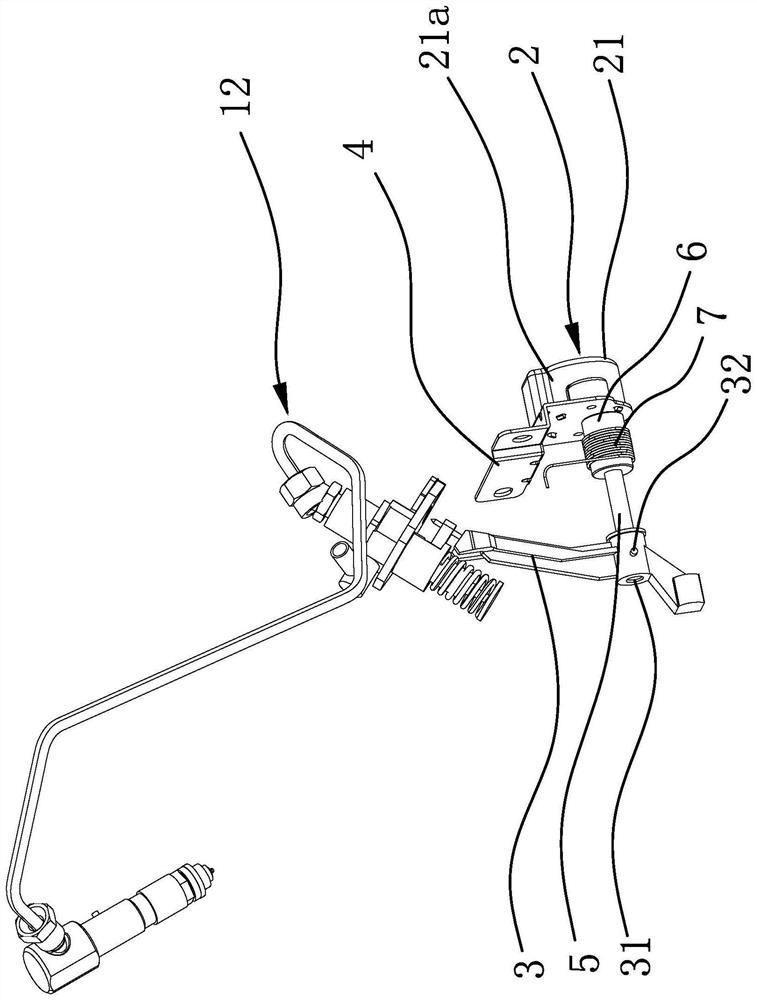

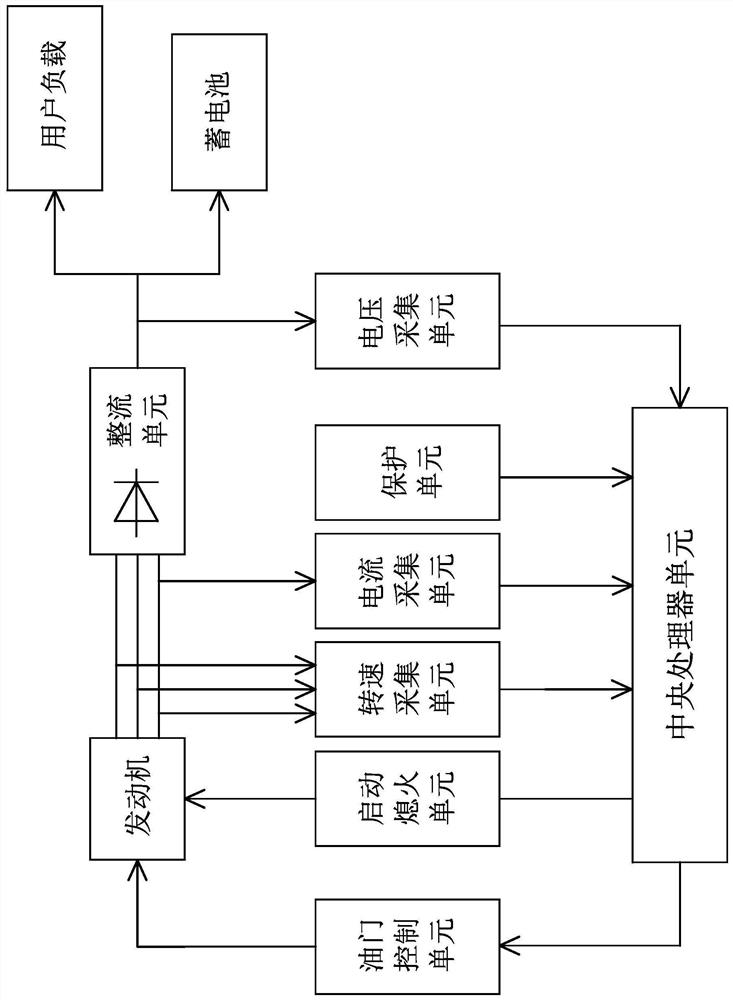

Electronic speed regulation structure in single-cylinder air-cooled diesel generator

PendingCN113027619AExtend your lifeEmission reductionSpeed sensing governorsMachines/enginesElectric machineMagneto

The invention provides an electronic speed regulation structure in a single-cylinder air-cooled diesel generator, and belongs to the technical field of fuel generators. The technical problem that the oil admission amount of an engine in an existing fuel generator cannot be accurately controlled is solved. The single-cylinder air-cooled diesel generator comprises a magneto and the engine, wherein the engine comprises a box body and an oil supply assembly arranged on the box body; an output shaft of the engine is connected with a rotor of the magneto, the electronic speed regulation structure comprises a driving motor and a shifting fork, and the shifting fork is connected with an accelerator in the oil supply assembly and can control the opening and closing angle of the accelerator; and an output shaft of the driving motor is connected with the shifting fork and can drive the shifting fork to swing back and forth. The electronic speed regulation structure further comprises a central processing unit and a rotating speed acquisition unit used for measuring and calculating the rotating speed of the magnetor. The electronic speed regulation structure can accurately and reliably control the fuel admission quantity and the rotating speed of the fuel engine.

Owner:台州市思德电子科技有限公司

Method and system for measuring speed of screw pump oil production well

ActiveCN108798640BSimple designReal-time monitoring of speedConstructionsMachines/enginesEngineeringScrew pump

The invention discloses a method and system for measuring the rotational speed of a screw pump oil production well, comprising: step 1, measuring the real-time active power of the screw pump oil production well; step 2, performing discrete Fourier transform based on the real-time active power; step 3, based on the discrete Fourier transform The power spectrum after Lie transform is analyzed and decomposed; step 4, based on the analysis and decomposition results, the speed of the screw pump production well is obtained. The advantages of the present invention are: by analyzing the electric power curve of the screw pump oil production well, real-time monitoring of the rotation speed of the screw pump well can be realized, and the estimation accuracy is high; the real-time monitoring of the rotation speed is conducive to the design of energy-saving and consumption-reducing measures; the safety of the present invention is high, practical It is more convenient to install, operate and maintain during application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com