Monitoring device for service performance of water pump

A technology for monitoring devices and water pumps, which is applied in measuring devices, pump testing, liquid variable capacity machinery, etc., and can solve problems such as increasing unit operating costs, reducing unit production efficiency, and machine wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

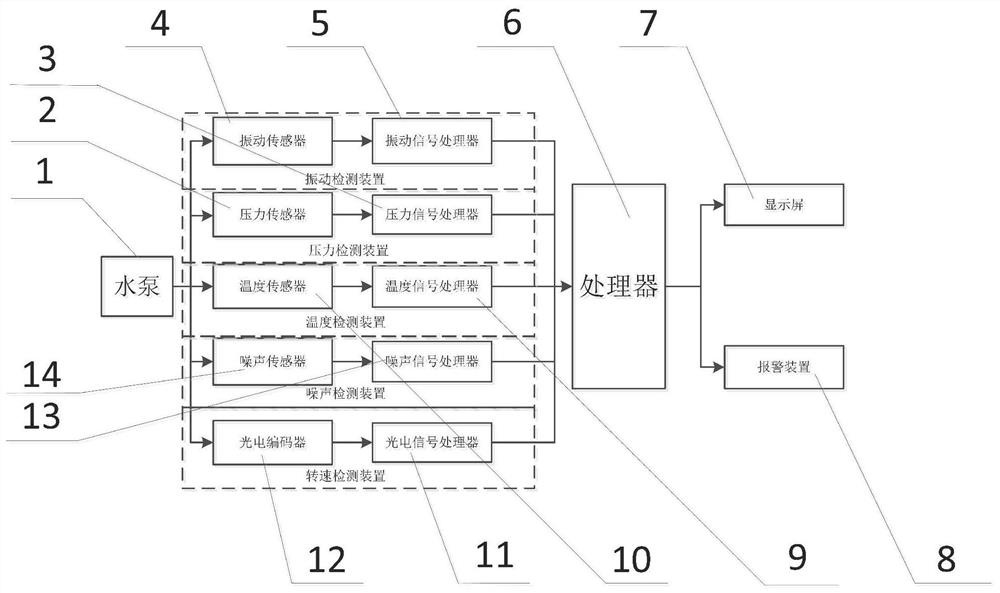

[0021] Below in conjunction with accompanying drawing this patent is further described. The technical features adopted by a performance monitoring device of a water pump in this patent include: a water pump (1), a vibration monitoring device, a pressure detection device, a temperature detection device, a noise monitoring device, a speed detection device, a processor (6), a display screen (7), alarm device (8).

[0022] The vibration monitoring device includes (4) a vibration sensor and (5) a vibration signal processor.

[0023] The pressure monitoring device includes a pressure sensor (2) and a pressure signal processor (3).

[0024] The temperature monitoring device includes a temperature sensor (10) and a temperature signal processor (9).

[0025] The noise monitoring device includes a noise sensor (14) and a noise signal processor (13).

[0026] The rotational speed monitoring device includes a photoelectric encoder (12) and a photoelectric signal processor (11).

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com