Device for preparing emulsion matrix conveying drag reducer

A technology of latex matrix and preparation equipment, which is applied in the directions of transportation and packaging, dissolution, mixer, etc., can solve the problems of poor drag reduction effect, matrix demulsification, high conveying pressure, etc., and achieve stability, sufficient stirring, and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

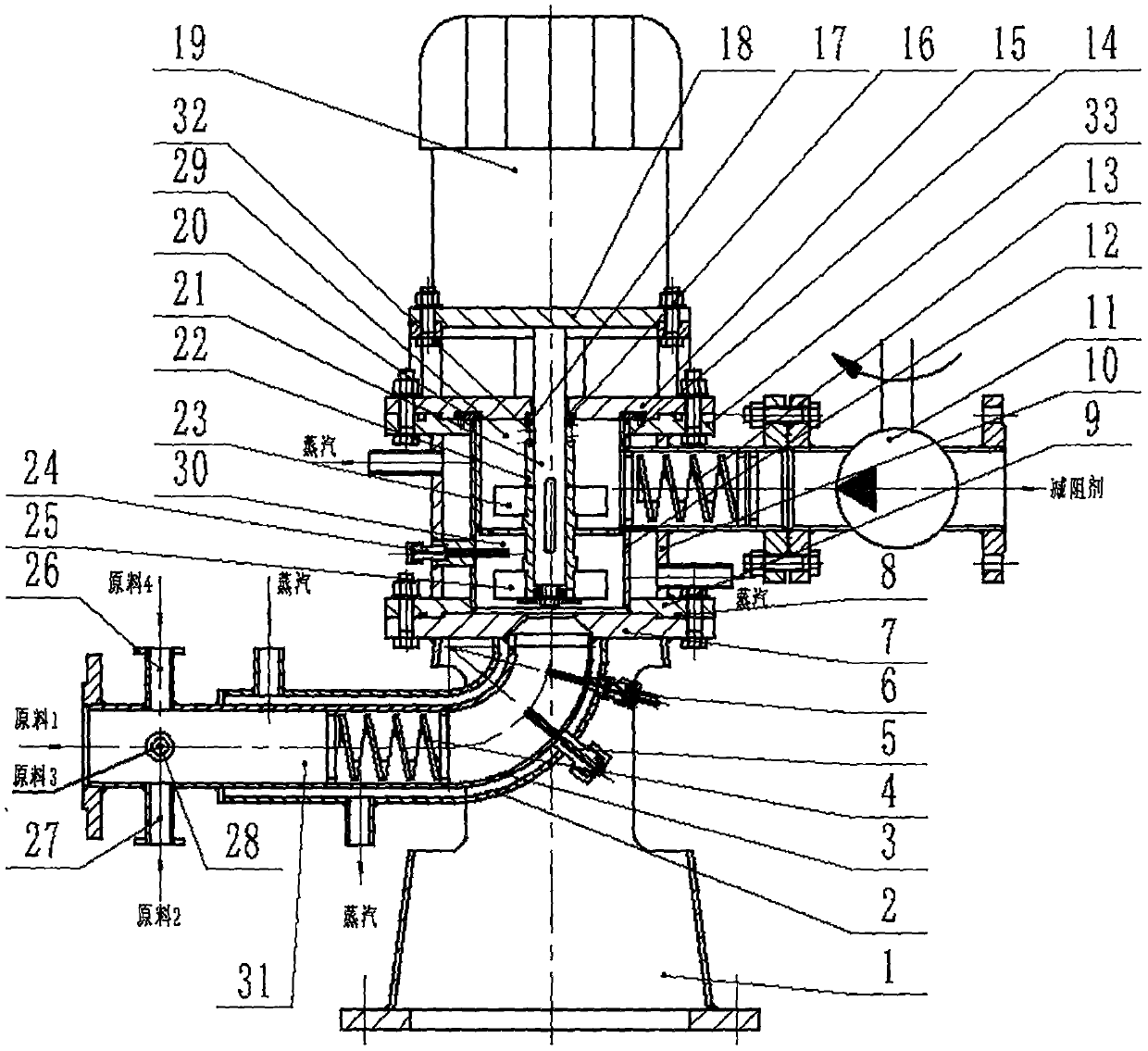

[0016] The specific implementation manner of the present invention will be further described below in conjunction with an embodiment, but the content of the present invention is not limited thereto.

[0017] 1. see figure 1 , the feeding channel 31 is made up of the feeding pipe inner sleeve 3 and the feeding pipe outer cover 2 made of φ95×6 stainless steel pipe and φ120×6 stainless steel pipe, and is welded with feeding port one 26, feeding port two 27, feeding port three 28, A temperature sensor 5 and a pressure sensor 6 are installed at the bend of the steam inlet and outlet pipe through screw connections, and a first-stage static mixer 4 is arranged at the front end of the bend pipe in the feed channel 31 .

[0018] 2. see figure 1 , the stirring shaft 21 is made of φ35 stainless steel round steel, and is equipped with a shaft sleeve 22, an impeller 23, a stirring blade 25, and a mechanical seal 16. The stirring blade 25 is hung in the primary mixing chamber 30 and connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com