Motor rotating speed monitoring device

A technology of motor speed and monitoring device, which is applied to devices using optical methods, etc., can solve the problems of inaccurate motor detection accuracy, and achieve the effect of convenient use and accurate monitoring results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

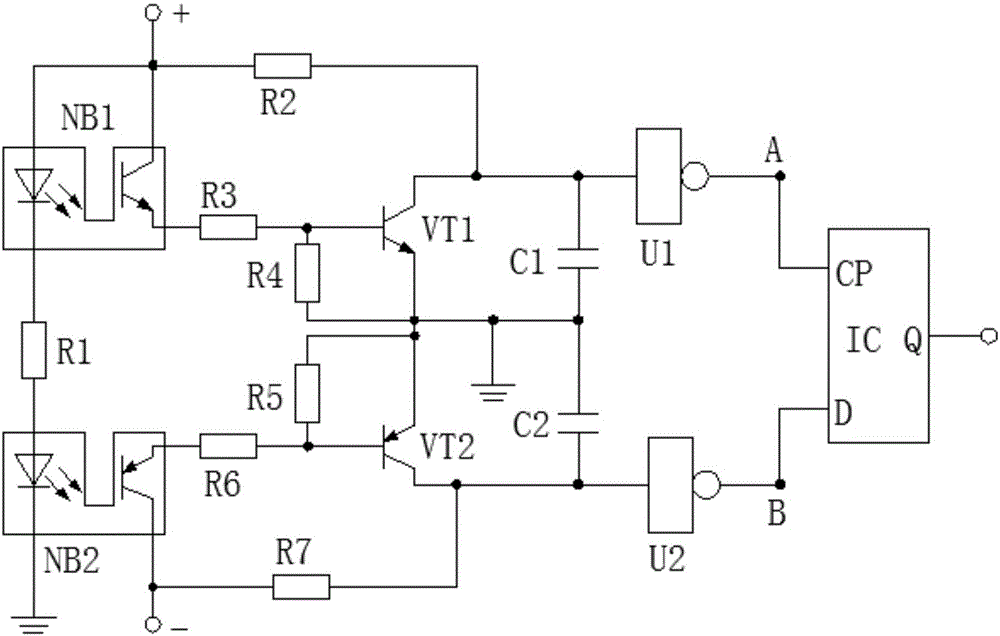

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] like figure 1 Shown: the present invention consists of a first optocoupler, a second optocoupler, a first resistor to a seventh resistor, a first capacitor, a second capacitor, a first triode, a second triode, a first NOT gate , the second NOT gate and double D flip-flops, the first resistor is 100Ω, the second resistor is 400Ω, the third resistor is 500Ω, the fourth resistor is 2kΩ, the fifth resistor is 27kΩ, the sixth resistor and the seventh resistor are both is 200Ω, the first capacitor is 300uf, the second capacitor is 470uf, the first transistor is a PNP transistor, the second transistor is an NPN transistor, and the first NOT gate and the second NOT gate are The NOT gate of model SN74AHC1G04 and the model of the double D flip-flop are MCR100-6 / 0.8A / 400V.

[0012] Further, the positive input end of the power supply is respectively connected to the first end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com