Clutch assembling tool

A technology for assembling tools and clutches, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low efficiency, poor consistency, clutch pedal vibration and other problems of pure manual assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

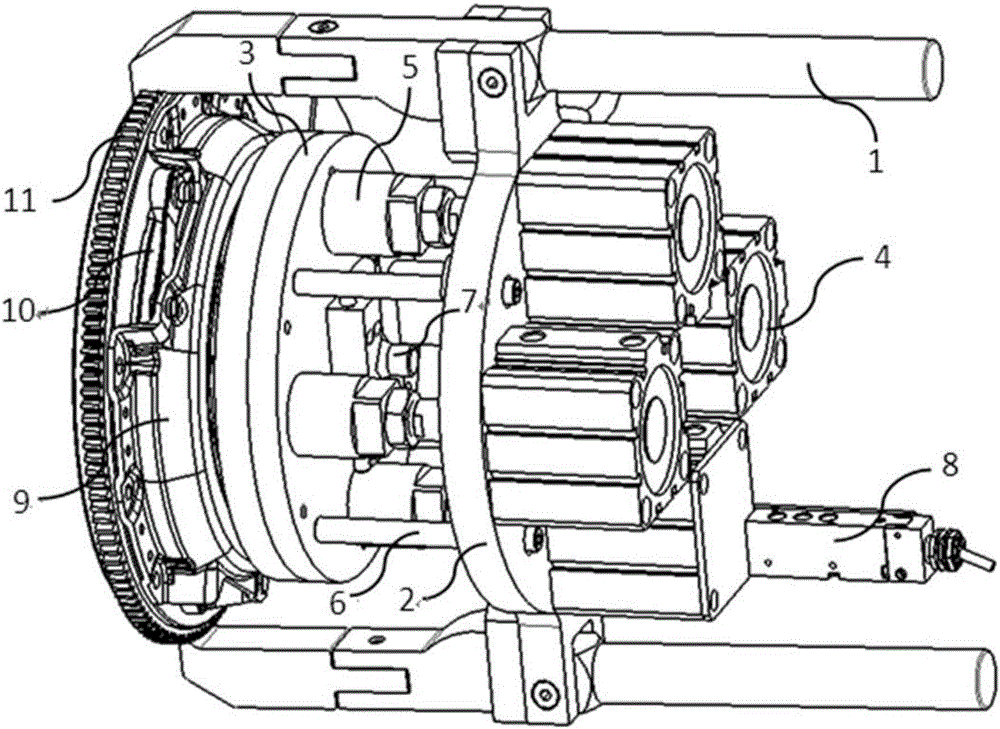

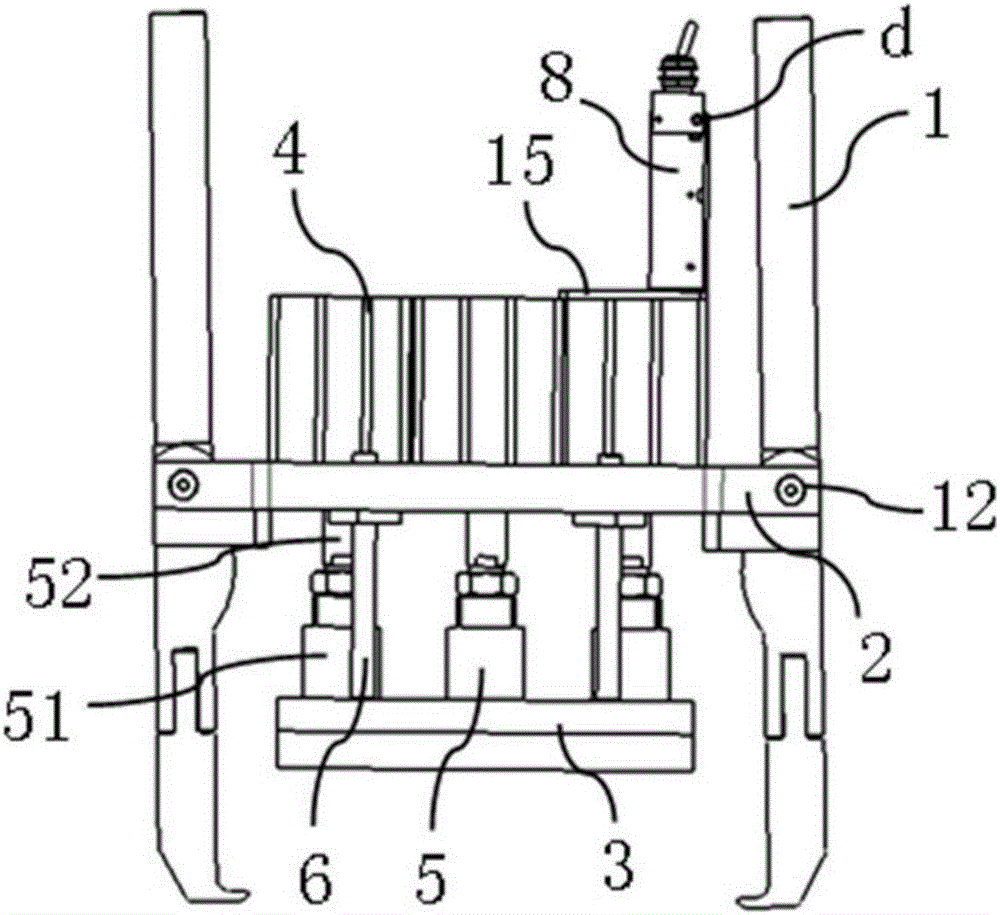

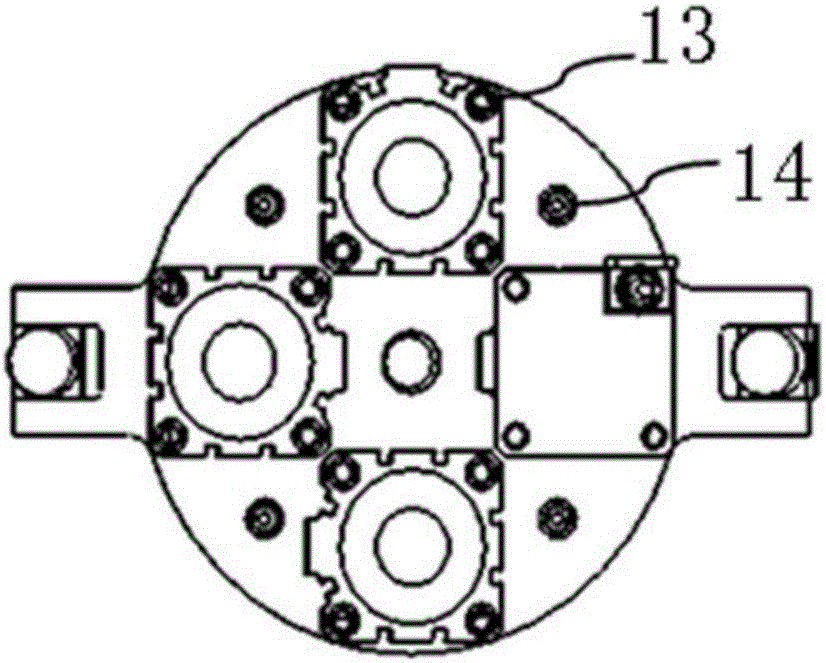

[0025] This application provides a clutch assembly tool, such as Figure 1 to Figure 3 As shown, it includes two claws 1, a fixed disc 2, a working disc 3, four cylinders 4, four cylinder push rod assemblies 5, six limit light rods 6 and a regulating valve 8.

[0026] A through hole is provided in the middle of each claw 1 .

[0027] There are two U-shaped open slots oppositely arranged on the fixed disc 2, and relative installation holes are provided on both sides of each U-shaped open slot; when assembling, a claw is installed in a U-shaped open slot , so that the mounting hole is opposite to the through hole, the connecting pin 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com