Voice coil actuator integrated with eddy current displacement sensor and assembling method

A displacement sensor, integrated electricity technology, applied in the direction of electromechanical devices, electric components, electric devices, etc., can solve the problems of poor assembly dimensional accuracy and consistency, low control accuracy of voice coil actuators, etc., to improve assembly accuracy and assembly. Dimensional consistency, overcoming the difficulty of measuring assembly dimensions, and improving the effect of performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

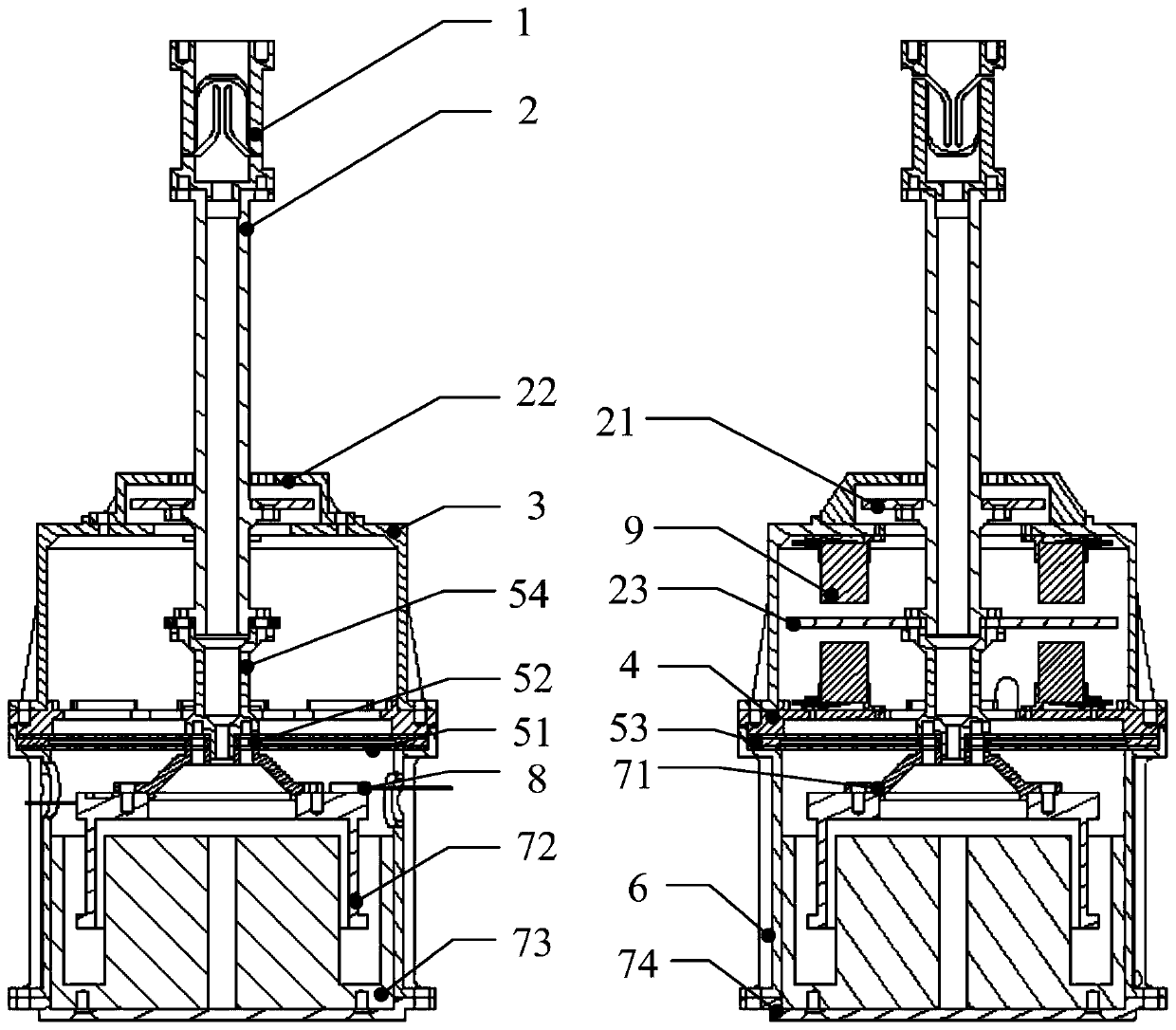

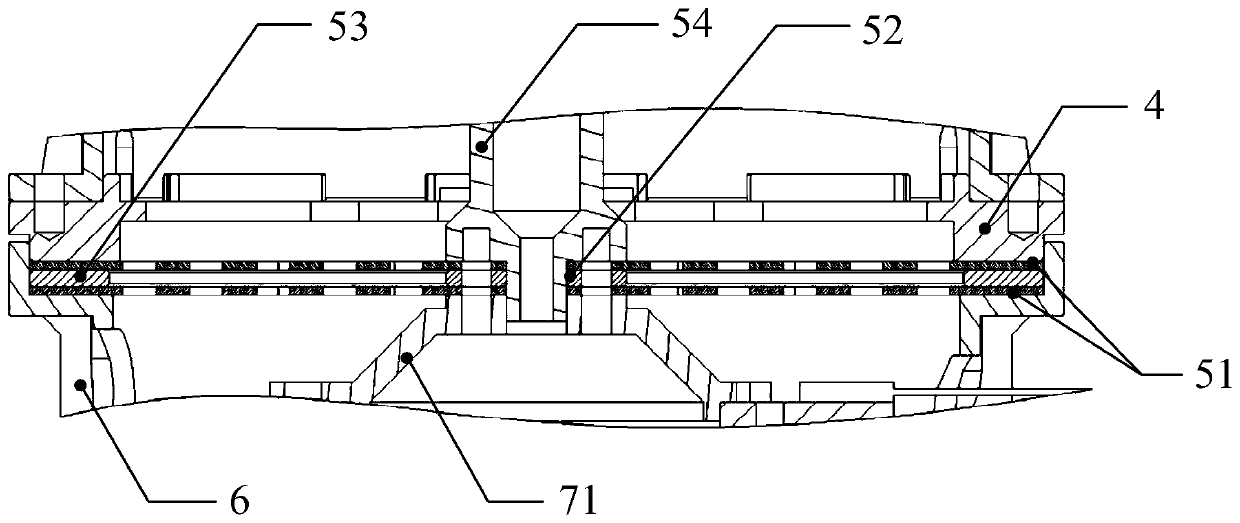

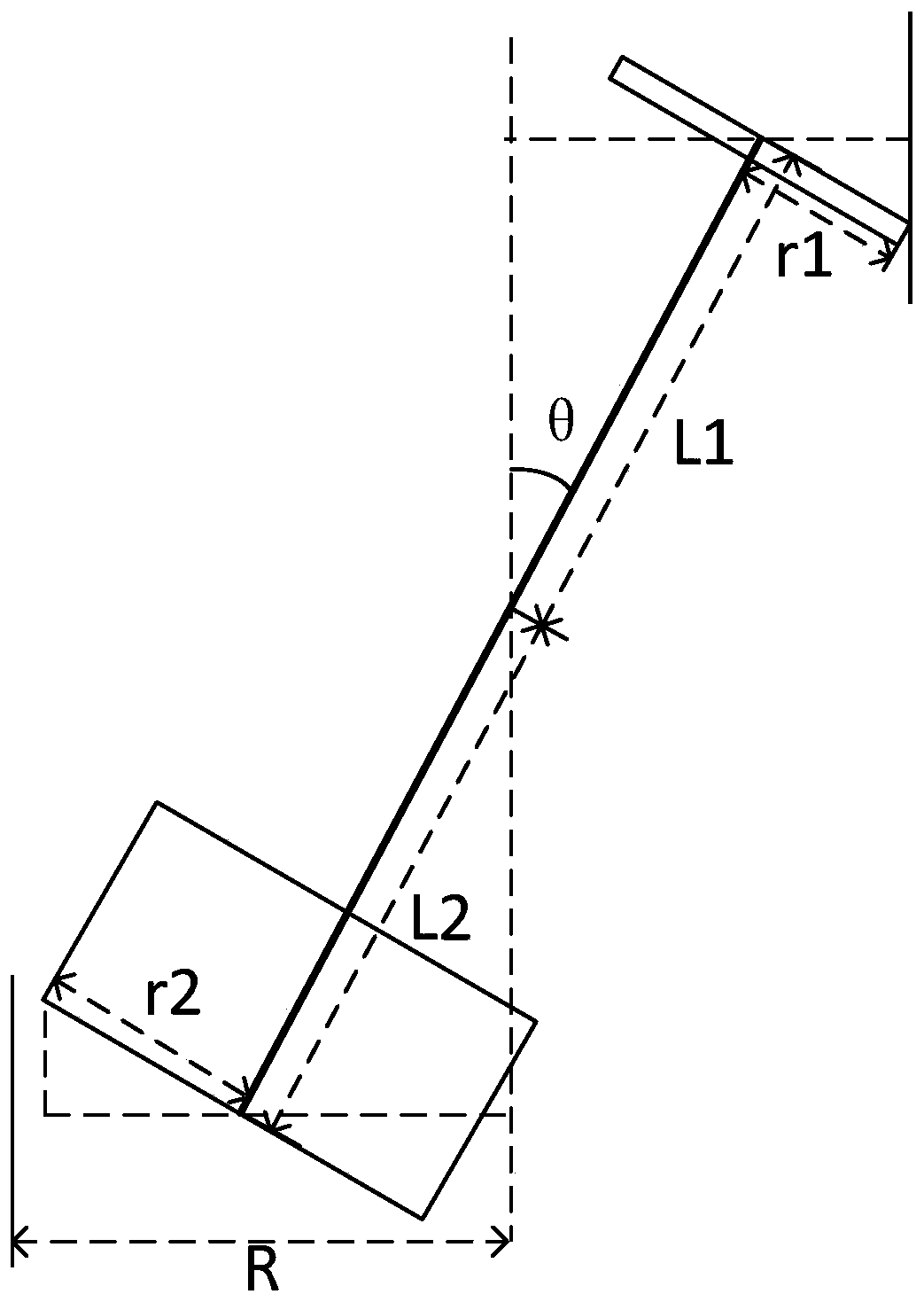

[0029] The invention provides a voice coil actuator and assembly method for an integrated eddy current displacement sensor, and proposes a high-precision actuator from the aspects of displacement measurement, temperature control, flexible structure design, limit design, and high-precision assembly method of the actuator. 1. Large load-bearing voice coil actuator and its assembly method. Compared with existing actuator products, the invention can greatly improve the control precision of the actuator. The invention adopts the method of coordinating the differential measurement of the eddy current displacement sensor and the calibration method, and the displacement measurement accuracy of the actuator can be improved to the submicron level.

[0030] In order to avoid large thermal deformation of the product displacement measurement part due to temperature changes, a flexible heat conduction cable is installed on the motor mover for active heat dissipation. A flexible heat conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com