Sectional method for sectionally assembled ring spinning frame

A technology for a spinning frame and a ring spindle, which is applied to the segmented field of assembly of a ring spinning frame, can solve the problems of shortening the assembly cycle, ensuring the assembly accuracy, and reducing the work intensity, so as to shorten the production and assembly cycle and ensure the assembly accuracy. , The effect of assembly consistency is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

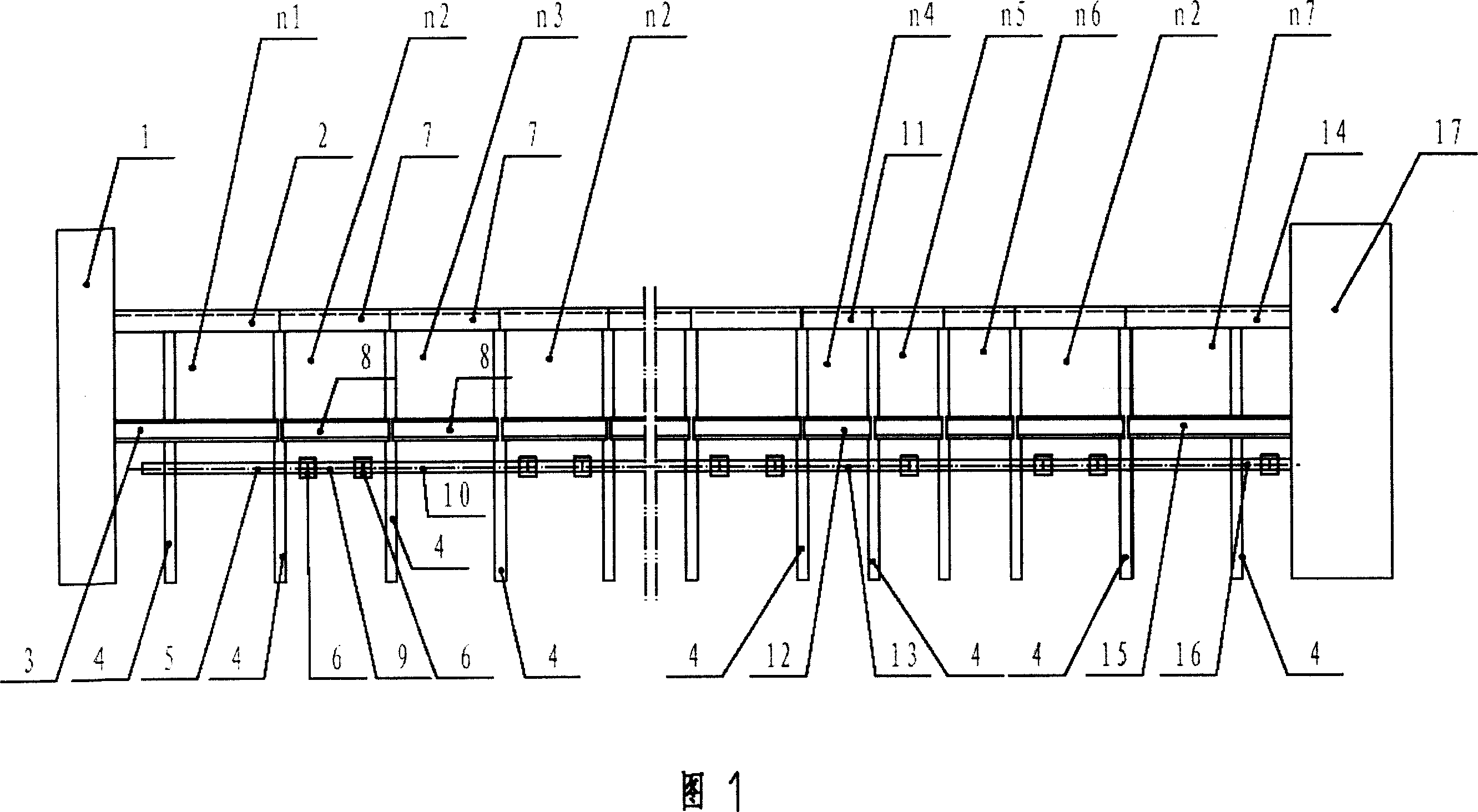

[0007] Embodiment 1: A segmented method for assembling the whole section of a ring spinning frame. The specific steps are as follows: a. Fix the headstock 1 of the ring spinning frame; The first dragon bar 3, the head section long main shaft 5, the head section whole section n1 that the coupling 6 forms is connected with the locomotive 1, c, will be made up of the second machine beam 7, two middle wallboards 4, the second dragon bar 8, The middle section of the long main shaft 10 and the middle section n3 composed of two shaft couplings 6 are fixed, d, the middle section of the loose section n2 composed of the second machine beam 7, the second dragon rib 8 and the short main shaft 9 is installed on the head section of the whole section n1 and Between the whole section n3 of the middle section, install the scattered section n2 and the whole section n3 of the middle section respectively behind e, the whole section n3 of the middle section, and by analogy, f, will be composed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com