Low-pressure turbine butt-joint assembling device capable of preventing balls from falling off

A low-pressure turbine and assembly device technology, applied in assembly machines, mechanical equipment, manufacturing tools, etc., can solve the problems of low centering accuracy and poor assembly consistency of components, achieve good assembly consistency, improve assembly centering accuracy, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Next, the technical solutions in the embodiments of the present invention will be described in contemplation in the embodiment of the present invention, and it is apparent that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in all other embodiments obtained without making creative labor.

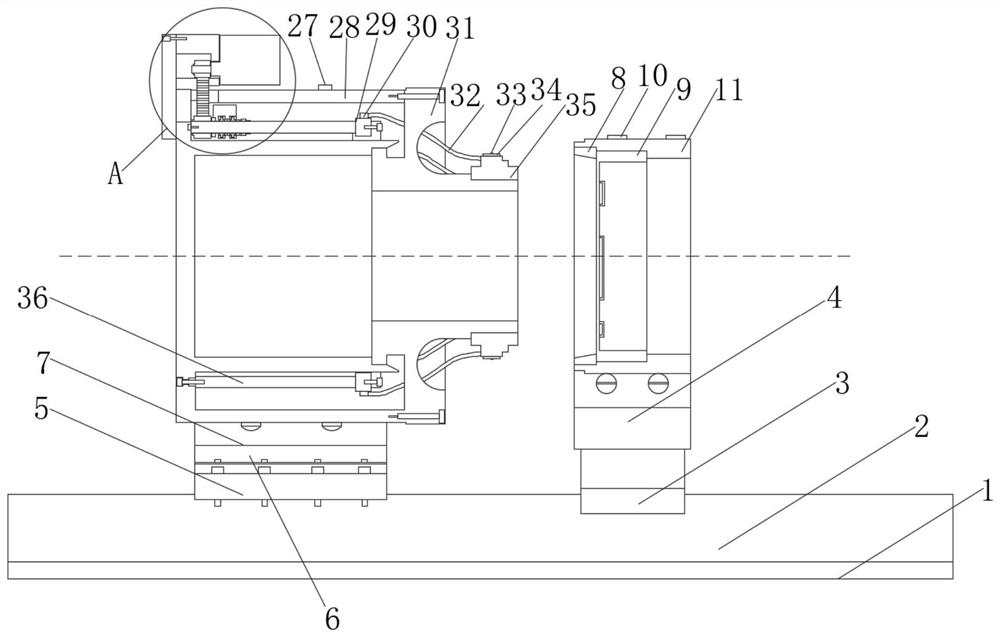

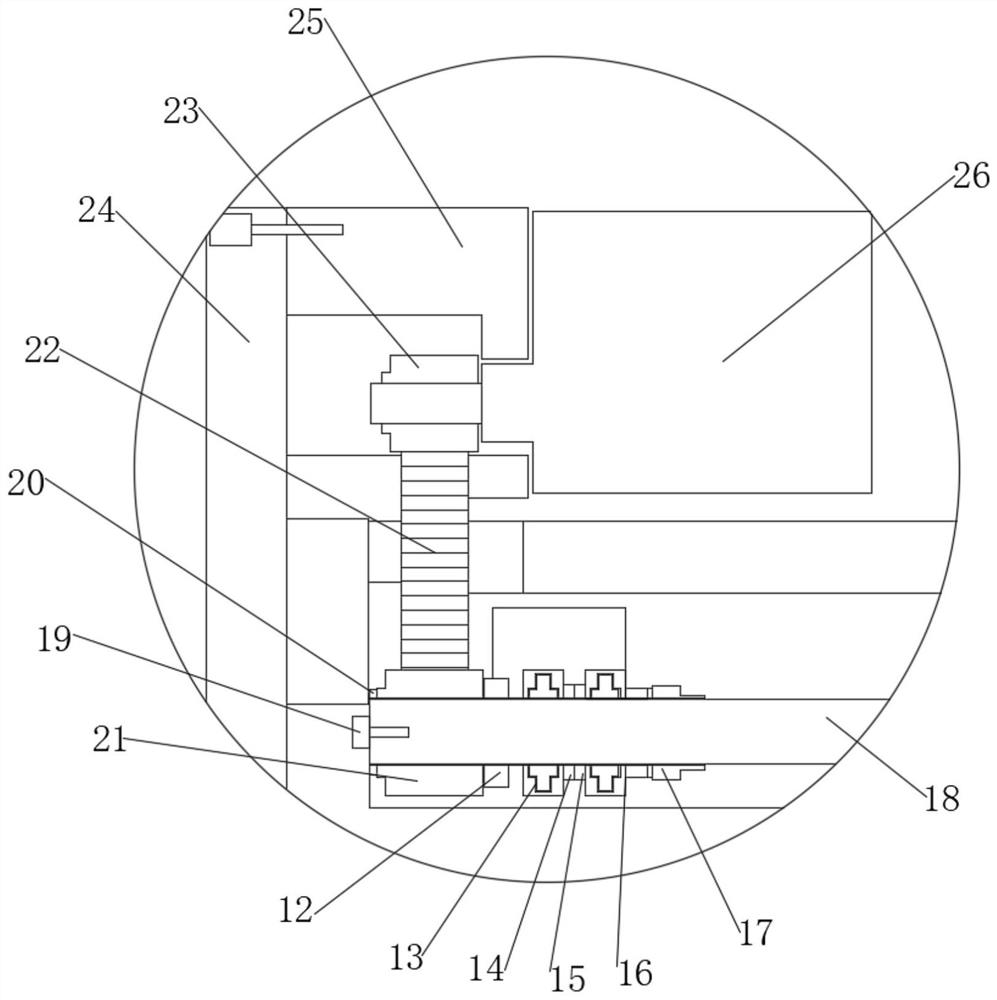

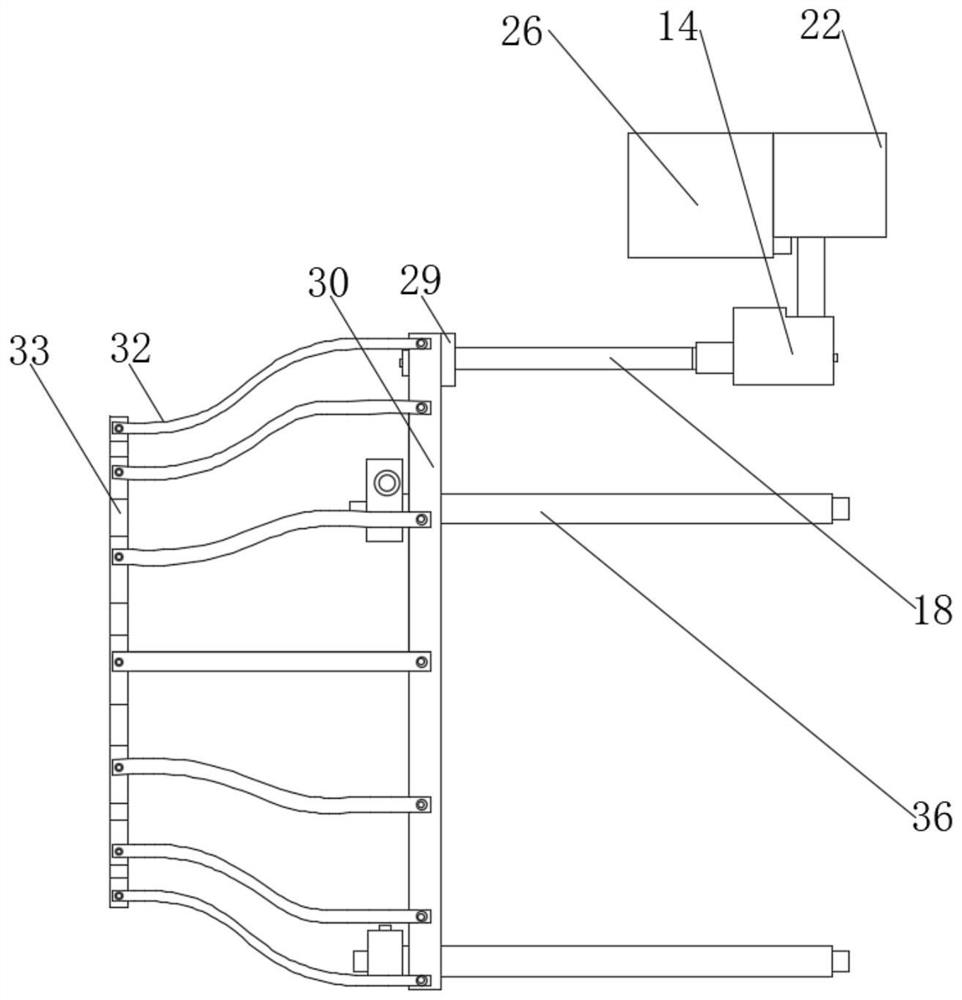

[0030]SeeFigure 1-7In the embodiment of the present invention, a low pressure turbine pairing assembly device that prevents the ball falls, includes an aluminum base 1, a push rod 30, a guide shaft 36, and a second V block having a second V block having a top portion of the aluminum base 1. 4, the inner wall of the second V-shaped block 4 is fixedly connected to the analog fan 11, and the surface of the simulated fan 11 is provided with a number of first stainless steel throat 10, and both ends of the first stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com