Mounting tool for camshaft bushing

A technology for installing tools and camshafts, used in manufacturing tools, hand-held tools, etc., can solve the problems of high destructive repair cost, high production input cost, poor assembly consistency, etc., and achieve stable and reliable assembly consistency, convenient operation, Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

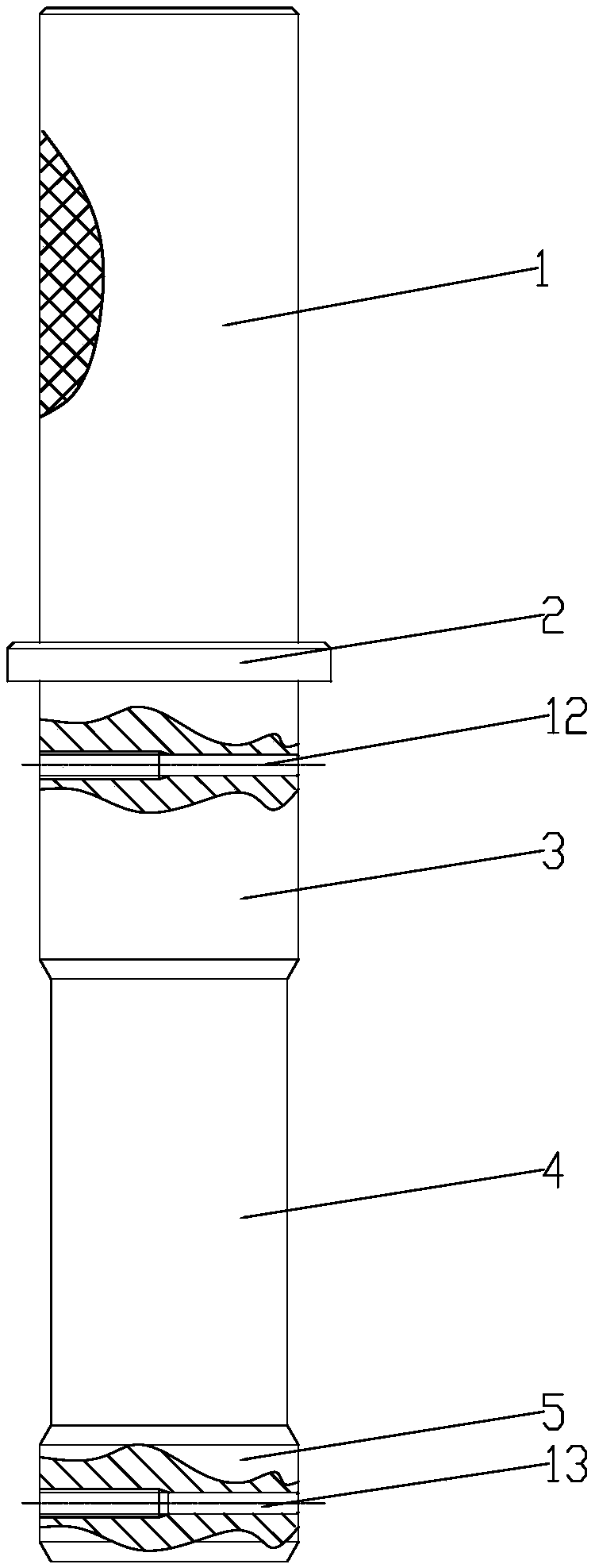

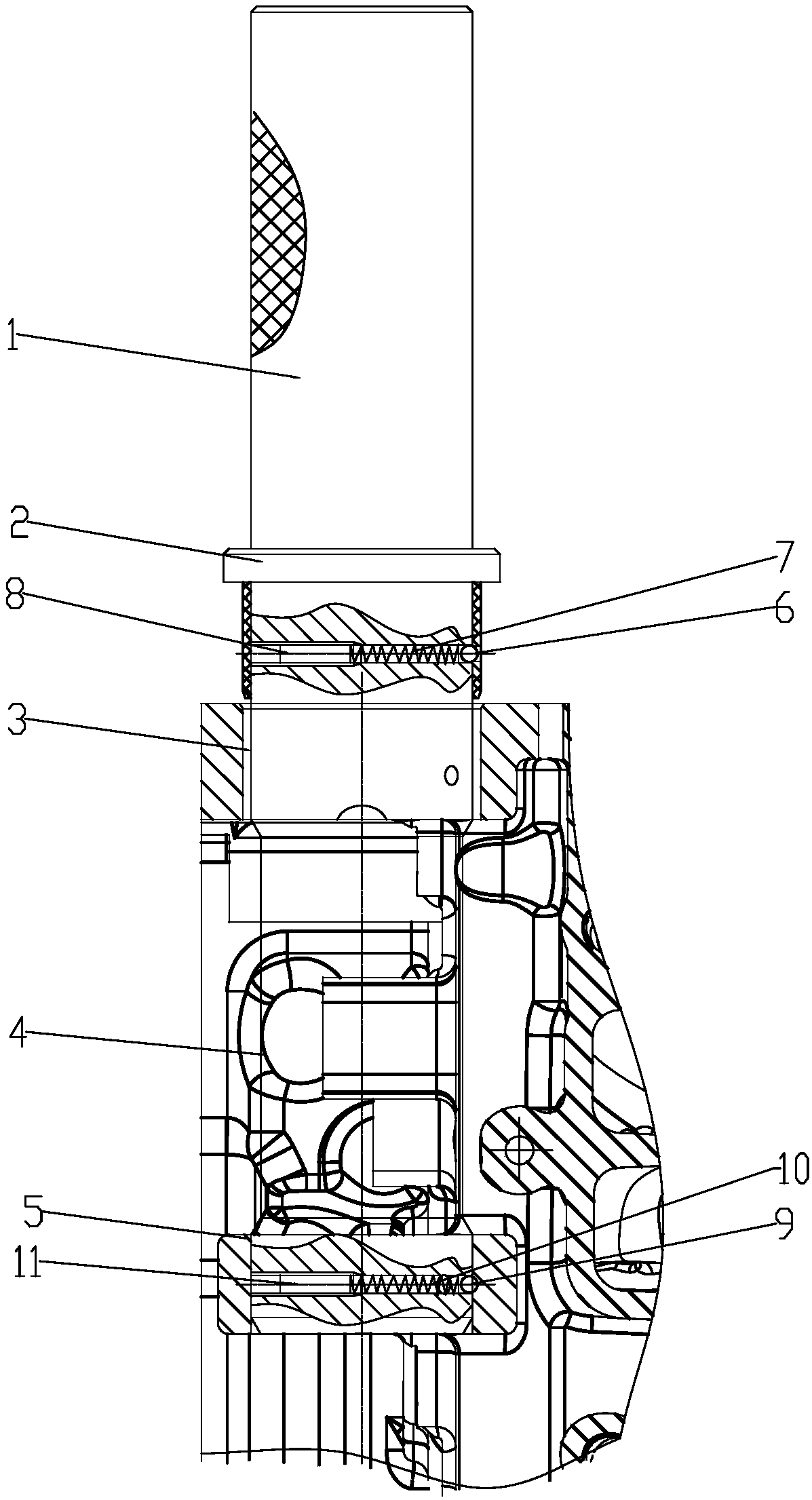

[0016] Such as Figure 1~2 As shown, the present invention mainly includes a compression rod, which is a cylinder. The pressure rod includes a handle part 1, a shoulder part 2, a bush installation part 3, a transition part 4 and a guide positioning part 5, the handle part 1, a shoulder part 2, a bush installation part 3, a transition part 4 and a guide positioning part The parts 5 are connected end to end in turn to form a whole.

[0017] The surface of the handle part 1 is provided with reticular lines, which improve the frictional force and facilitate manual clamping.

[0018] The end face of the convex shoulder 2 is perpendicular to the axis of the pressure rod, so as to ensure that the bush can be evenly stressed at 360° during the process of using tools to install the bush, and reduce the deformation of the bush.

[0019] The diameter of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com