Automatic assembling equipment for riveting and extruding points of jacks and protection sleeves and assembling method thereof

A protection sleeve, automatic assembly technology, applied in the assembly/disassembly of contacts, metal processing equipment, feeding devices, etc., can solve the problems of large workload, low manual assembly efficiency, and complex assembly methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

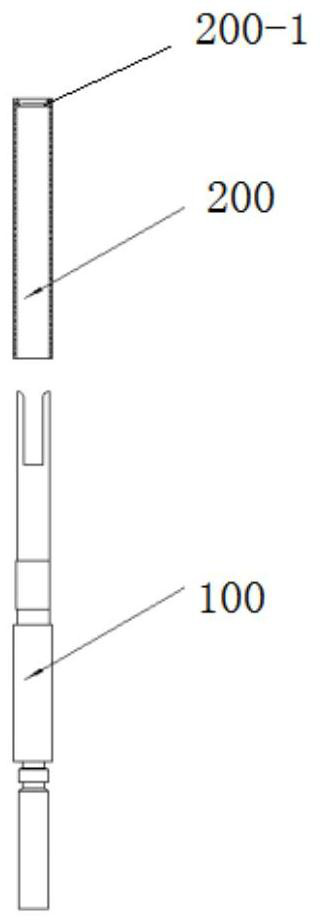

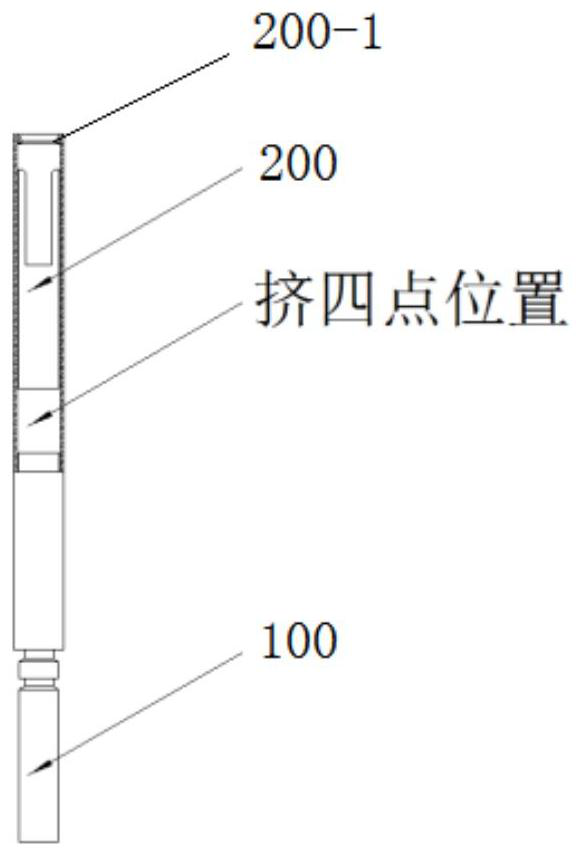

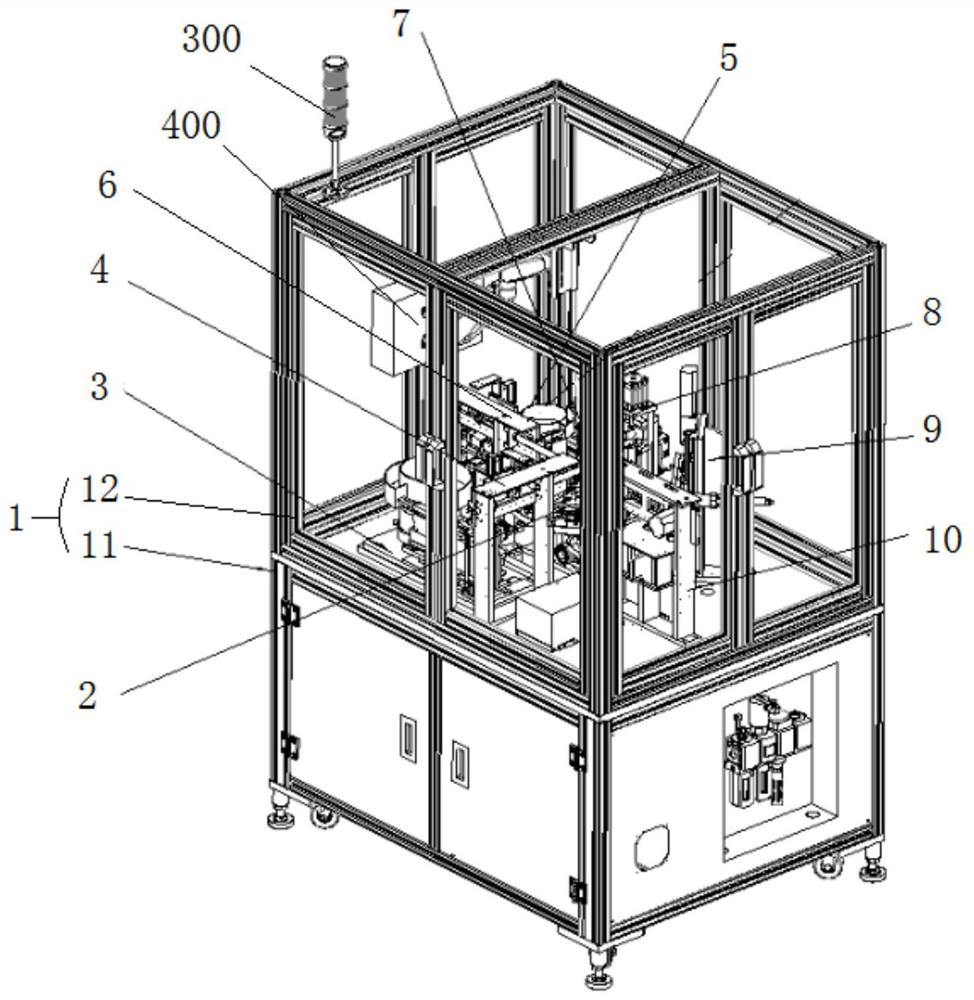

[0105] refer to Figure 3-Figure 4 , an automatic assembly device for riveting and extruding points between a socket and a protective sleeve, the automatic assembly device includes a frame assembly 1, a rotary tooling assembly 2, a socket wrong material distribution assembly 3, a socket feeding assembly 4, a protection Sleeve direction selection component 5, protective casing feeding component 6, protective casing detection component 7, bidirectional riveting component 8, adjustable stroke extrusion point component 9 and finished product unloading component 10;

[0106] The frame assembly 1 includes a case 11 and an outer cover 12. The mounting boards for electronic control devices and pneumatic devices are placed in the case 11, and the remaining space is used for wiring. An indicator light 300 and a touch screen mounting bracket 400 are installed on the cover 12 .

[0107] The upper surface of the cabinet 11 is a workbench, and the rotary tooling assembly 2 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com