Front suspension assembly for power assembly

A powertrain and front suspension technology, applied in the field of vehicles, can solve problems such as affecting vibration isolation performance, and achieve the effect of removing over-constraints, reducing transmission paths, and ensuring convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

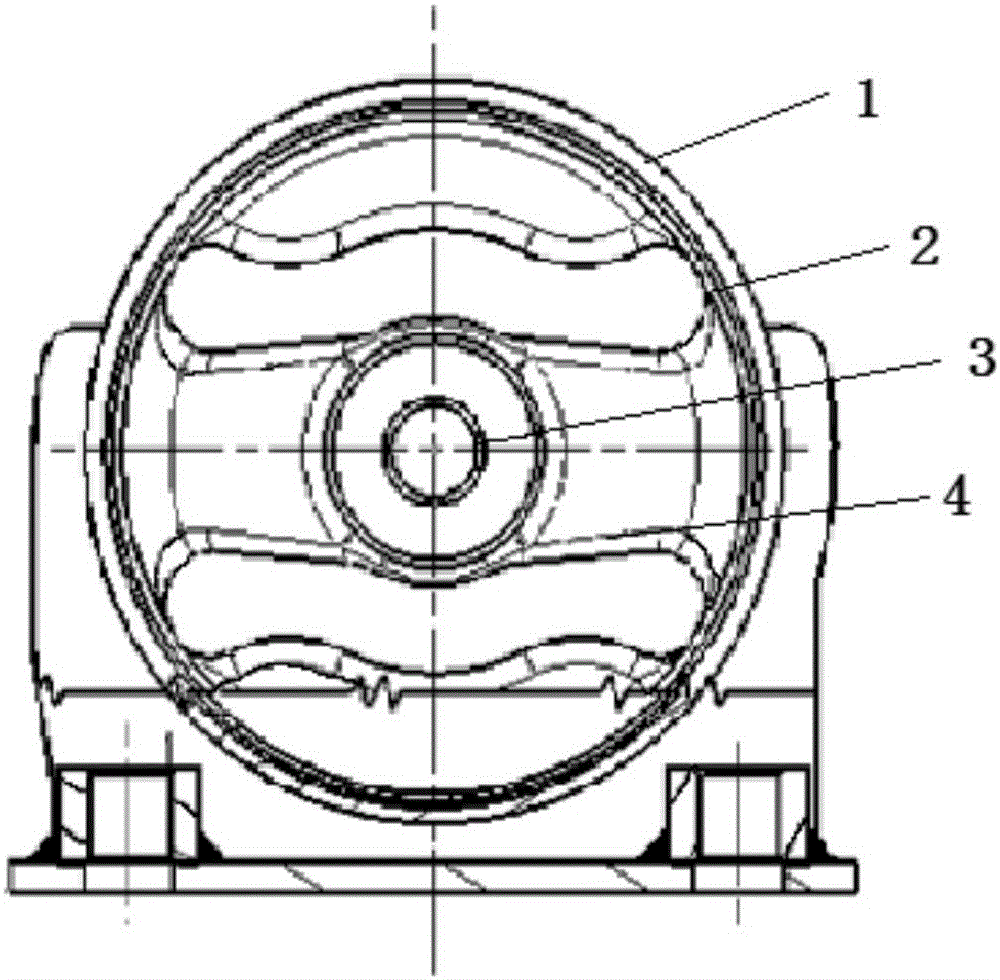

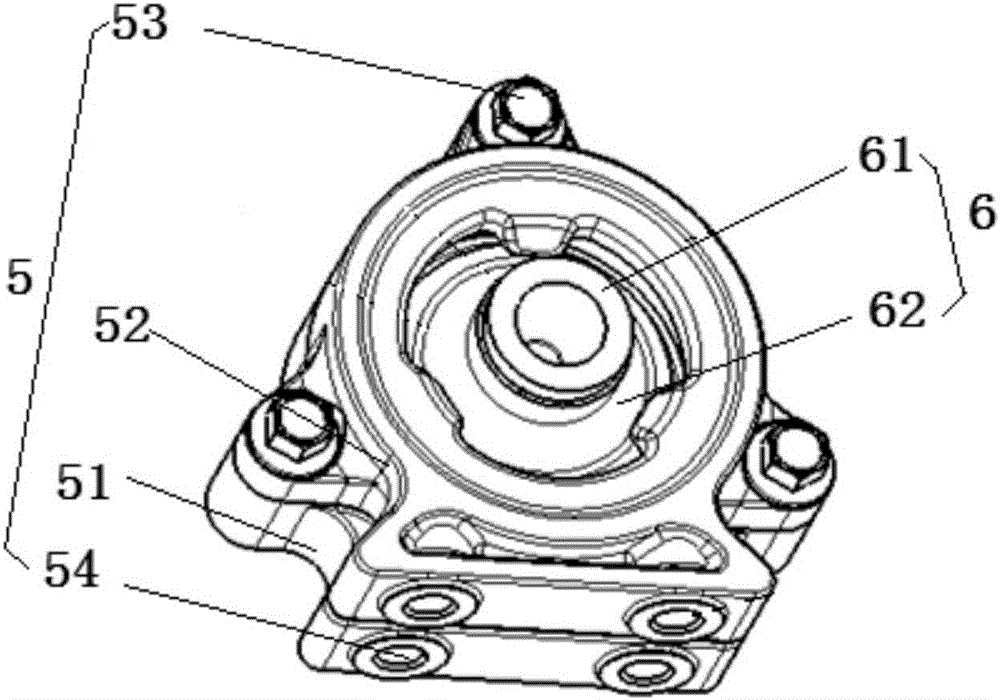

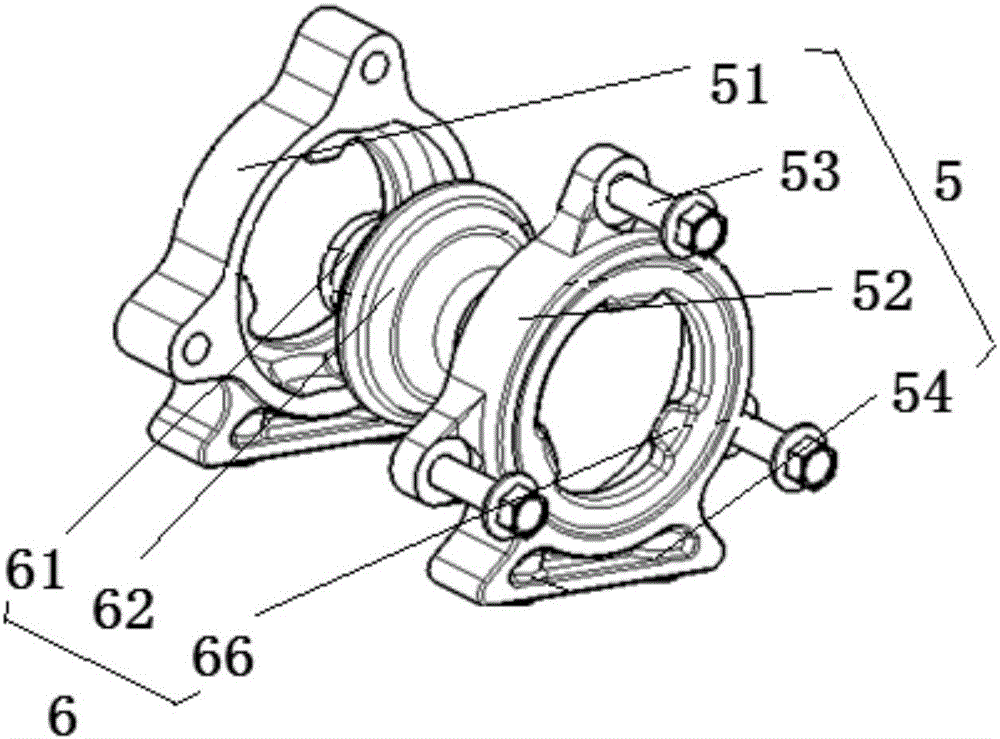

[0039] figure 2 It is a structural schematic diagram of a front suspension assembly for a powertrain according to an embodiment of the present invention. like figure 2 As shown, the front suspension assembly for the powertrain can be arranged on the front side of the powertrain (not shown in the figure) through the connecting bracket (not shown in the figure), including the suspension bracket 5 and the inner tube Component 6, the suspension bracket 5 can be fixedly connected with the sub-frame, the suspension bracket 5 includes a first bracket 51 and a second bracket 52, and an accommodation space is formed between the first bracket 51 and the second bracket 52; the inner tube assembly 6 It includes an inner tube 61 and a rubber main spring 62, the rubber main spring 62 and the inner tube 61 are vulcanized into one structure, and the inner tube assembly 6 can be movably placed in the accommodating space.

[0040] Specifically, the inner tube assembly 6 is vulcanized togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com