Adjustable Drive Half Shaft Constrained Modal Test Fixture

A technology for driving half shafts and restraining modals. It is applied in the testing of measuring devices, workpiece clamping devices, and mechanical components. It can solve problems such as performance evaluation and constrained modal testing, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

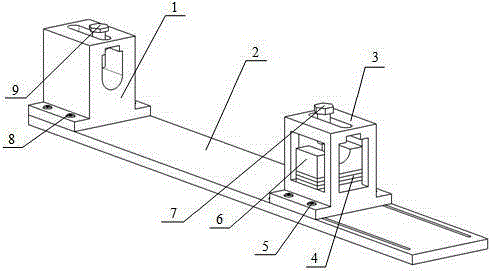

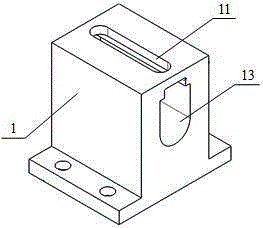

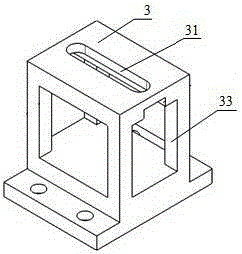

[0018] see Figure 1 to Figure 6 , the adjustable driving half-shaft constrained modal test fixture includes a strip-shaped base 2 , a fixed bracket 1 and a moving bracket 3 . The fixed bracket 1 is fixed on one end of the base 2 by bolts 8 . The middle part of the fixed bracket 1 is provided with the first assembly hole 13 which is U-shaped in cross section along the longitudinal direction of the base, and the first T-shaped groove 11 is provided on the top of the fixed bracket 1 along the longitudinal direction of the base, and the first T-shaped groove 11 and the first assembly The hole 13 communicates, and its wide groove is below the narrow groove. The first bolt assembly 9 matched with it is arranged in the first T-shaped groove 11. The first bolt assembly 9 is composed of a bolt and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com