Assembling platform and assembling method thereof for high-speed parallel robot

An assembly platform and assembly method technology, which is applied in the direction of mechanical equipment, material gluing, and connecting components, can solve the problems of inapplicable high-efficiency assembly, etc., and achieve the effect of solving low efficiency of manual assembly, ensuring assembly quality, and good assembly consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

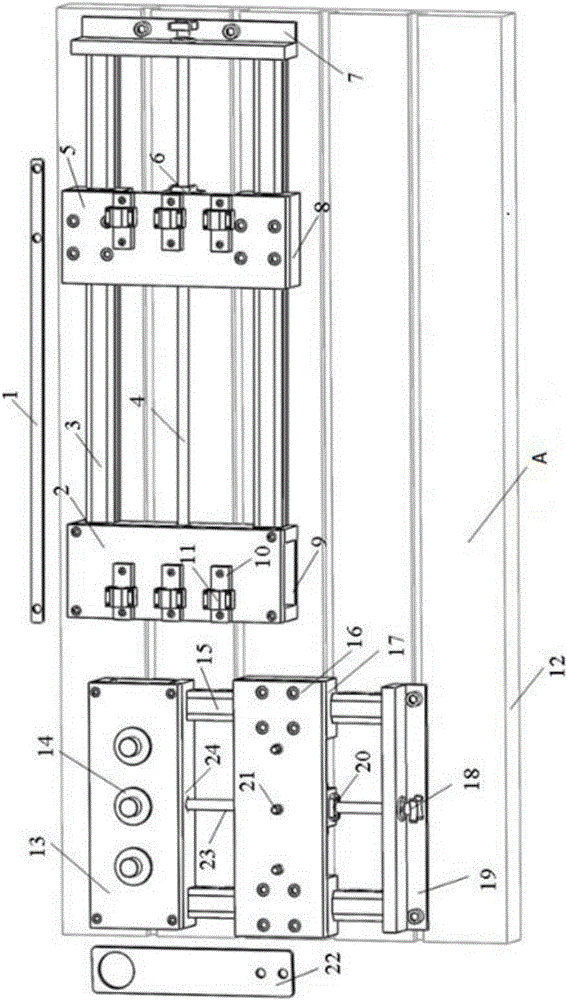

[0030] Reference attached figure 1 , The structure of a high-speed parallel robot assembly platform of the present invention is as follows: base 12, said base 12 has a flat upper surface A; active arm sub-assembly platform and driven arm sub-assembly platform.

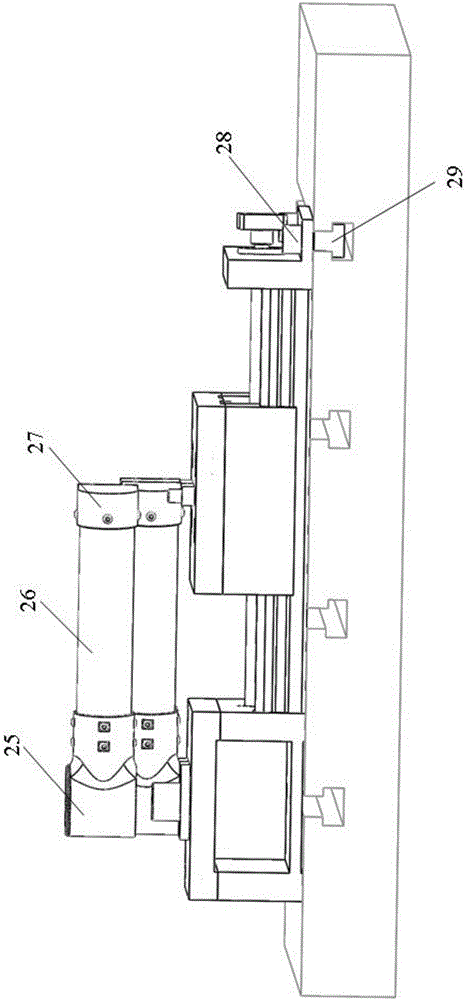

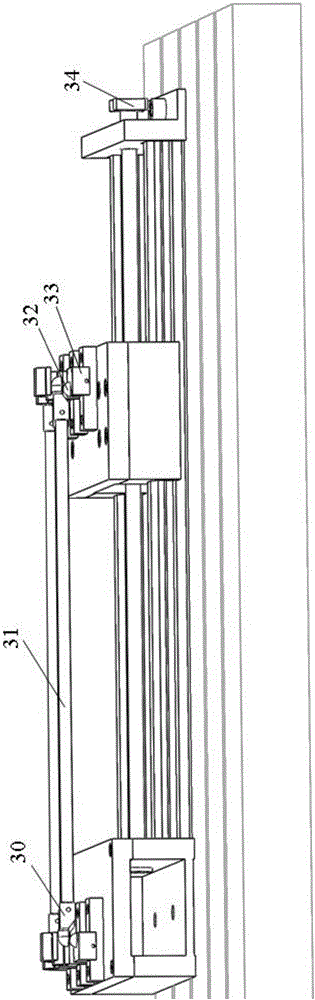

[0031] The active arm sub-assembly platform includes: the fixed platform base I24 and the tail plate I19, and the fixed platform base I24 and the tail plate I19 are assembled on the above-mentioned flat upper surface A through T-nuts 29 and socket head cap screws 28 respectively. In the groove; the fixed platform I13, the fixed platform I13 is installed on the above-mentioned fixed platform base I24, and the fixed platform I13 is drilled with threaded holes for installing the connecting shaft I14; the guide rail I15, the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com