Machine for automatically tightening wheel hub adjustment nut with holes, realizing hole alignment and measuring pre-tightening force and use method of machine

A technology for adjusting nuts and tightening machines, which is used to measure torque/torsion force and other directions during tightening, which can solve the problems of high work intensity and inability to realize automatic operation, and achieve the liberation of manpower, safe and reliable tightening operation, high assembly accuracy and consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

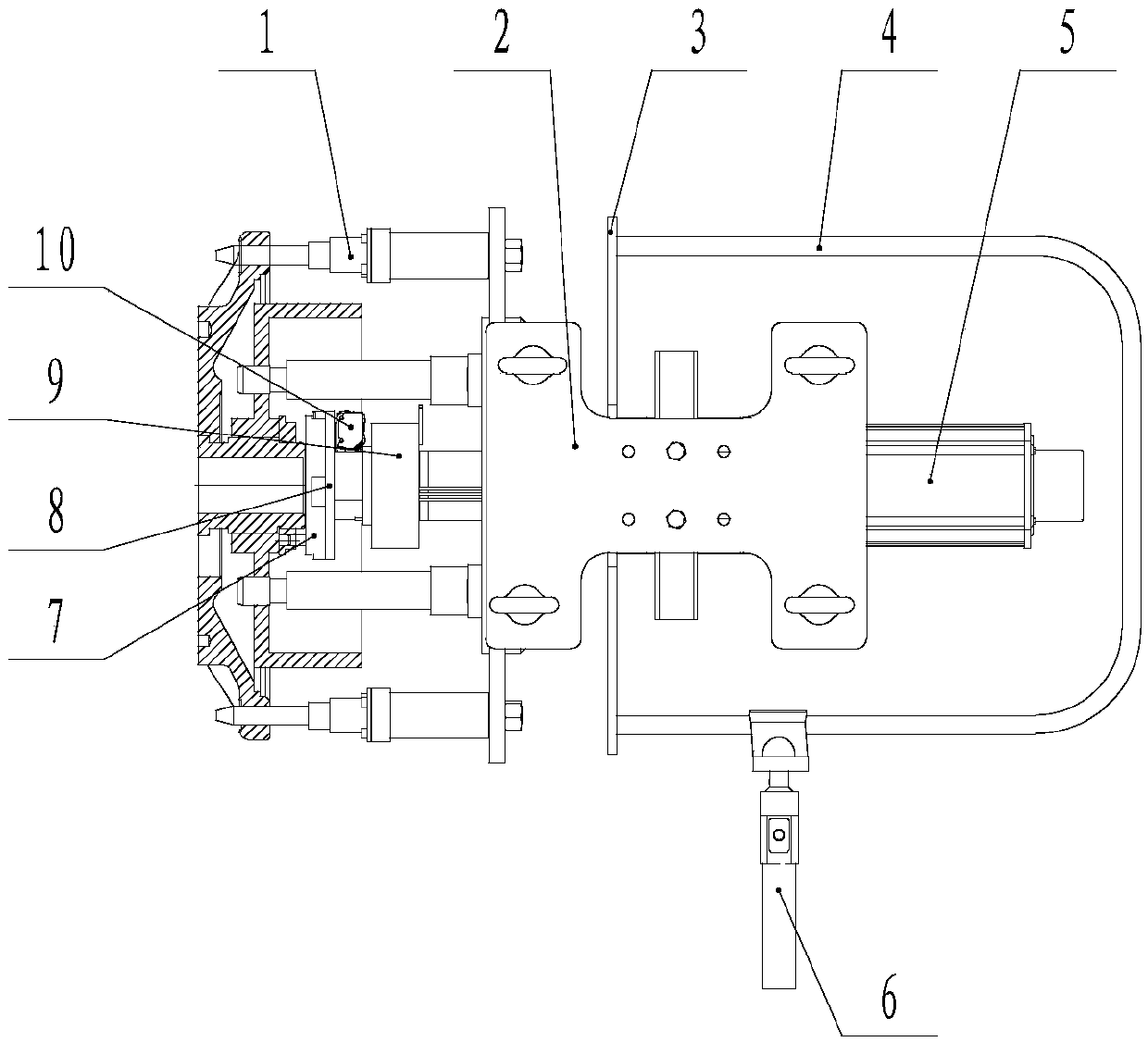

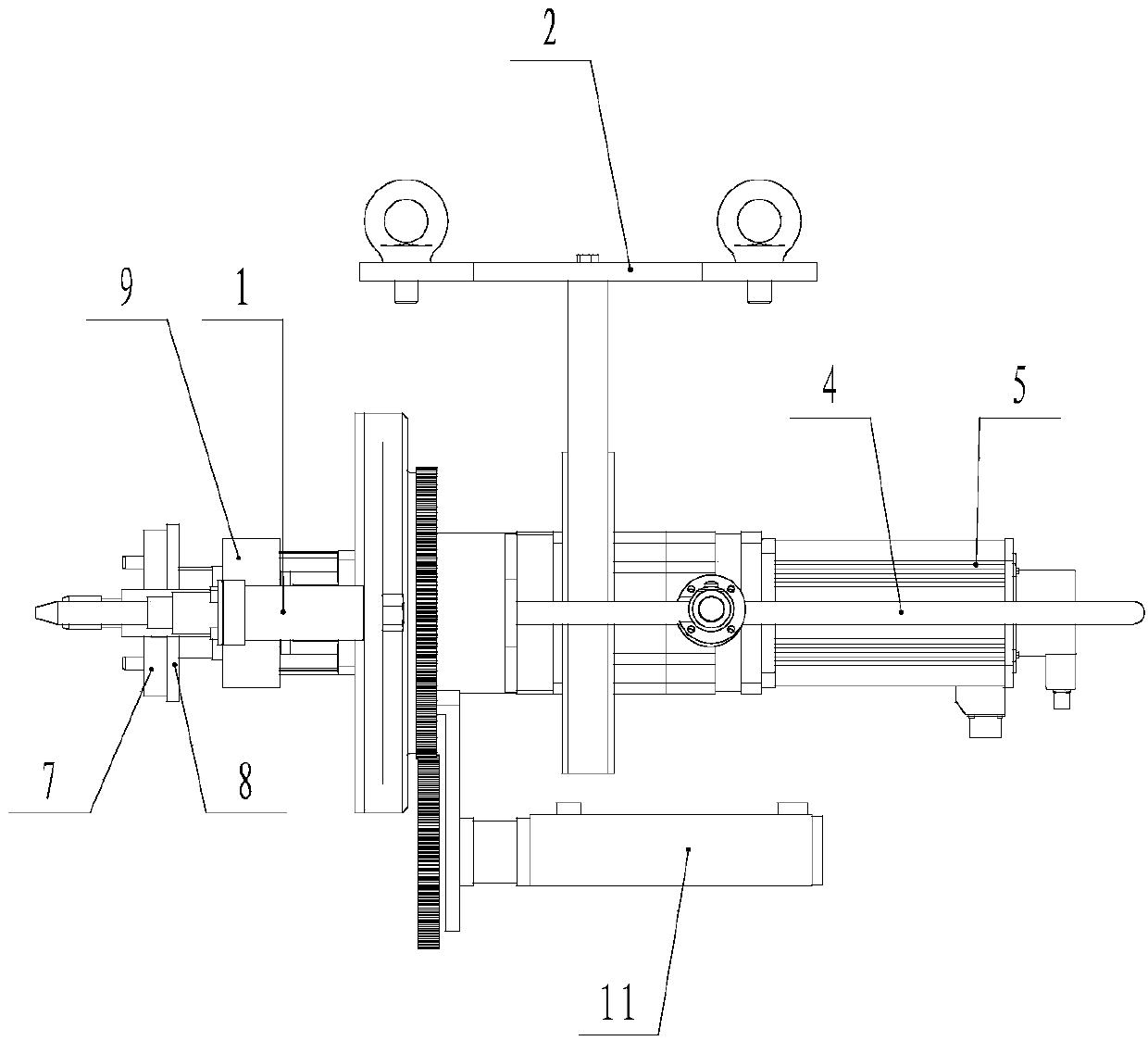

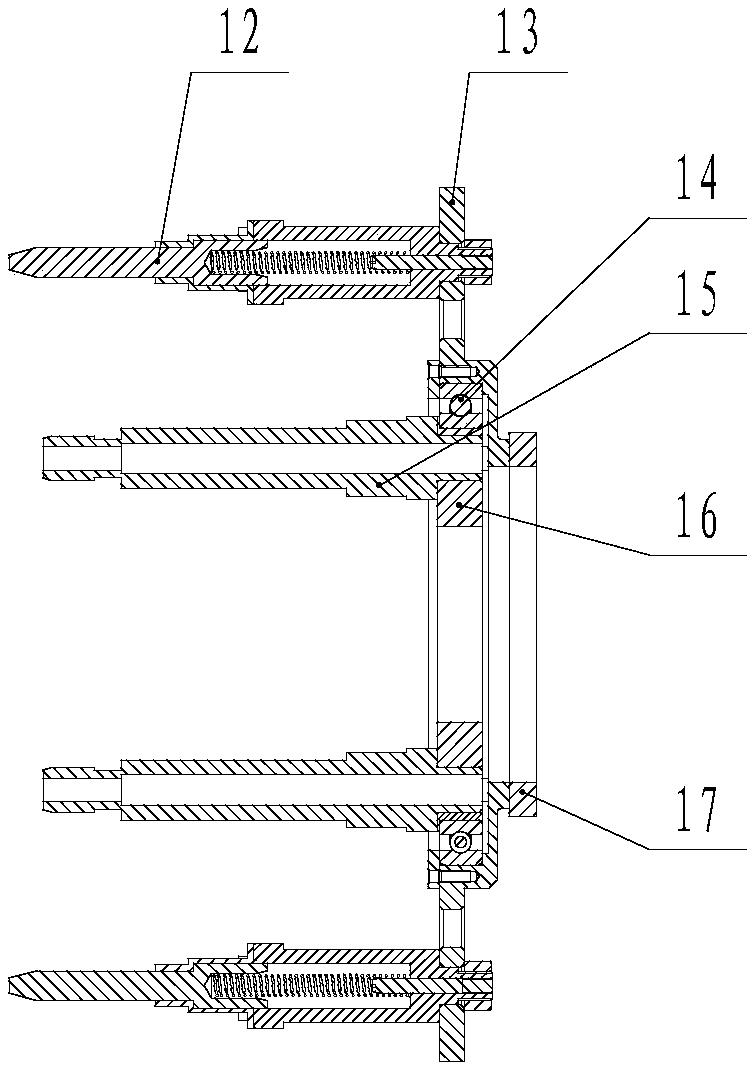

[0027] Such as figure 1 , figure 2 , Figure 5 , Figure 6 As shown, the automatic tightening, alignment and pretightening force measuring machine of the wheel hub adjustment nut with holes described in the present invention includes: a reaction force measuring device 1, a hoisting device 2, a nut tightening machine 5, a nut tightening disc 7, and a sensor mounting disc 8. Through hole slip ring 9, laser sensor 10, measuring axis 11 and PLC controller. The reaction force measuring device 1 is connected to the output shaft of the nut tightening machine 5, the hoisting device 2 is connected to the casing of the nut tightening machine 5, the measuring shaft 11 is meshed with the reaction force measuring device 1 through gears, and the output end of the nut tightening machine 5 is connected to the sensor The mounting plate 8 is connected to the handle fixing plate 3 at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com