Pre-edge-rolling device

A pre-rolling and assembly technology, which is applied in the field of automobile production, can solve the problems of large space occupied by the tire mold of the compression mold assembly, difficulty in maintaining the quality of pre-folding, and affecting the rhythm of normal production, so as to improve space utilization and convenience. The effect of early debugging and short debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

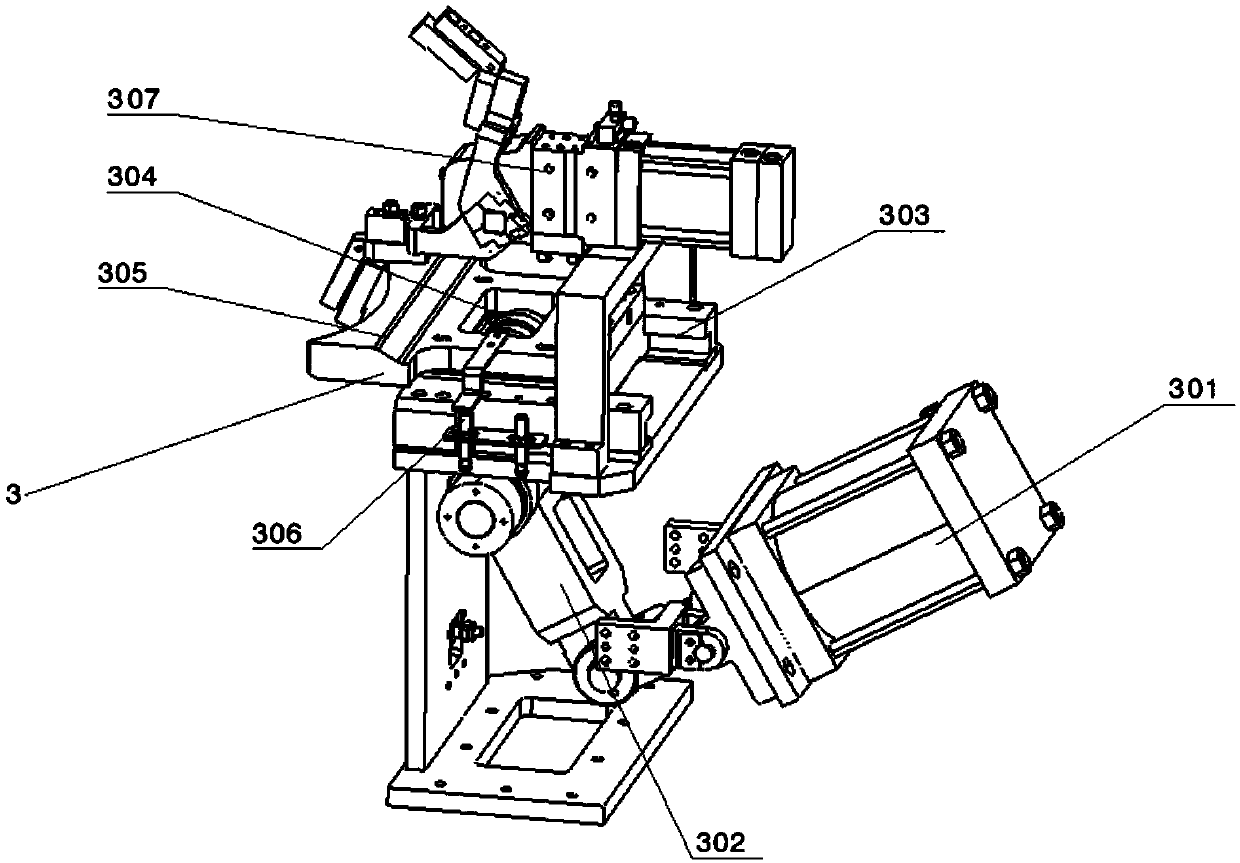

[0033] A pre-hemming device such as Figure 5 As shown, it includes a turntable mechanism 4 provided with a plurality of pre-rolling stations, and each pre-rolling station is provided with a set of positioning mechanism and a set of angular push mechanism 3 .

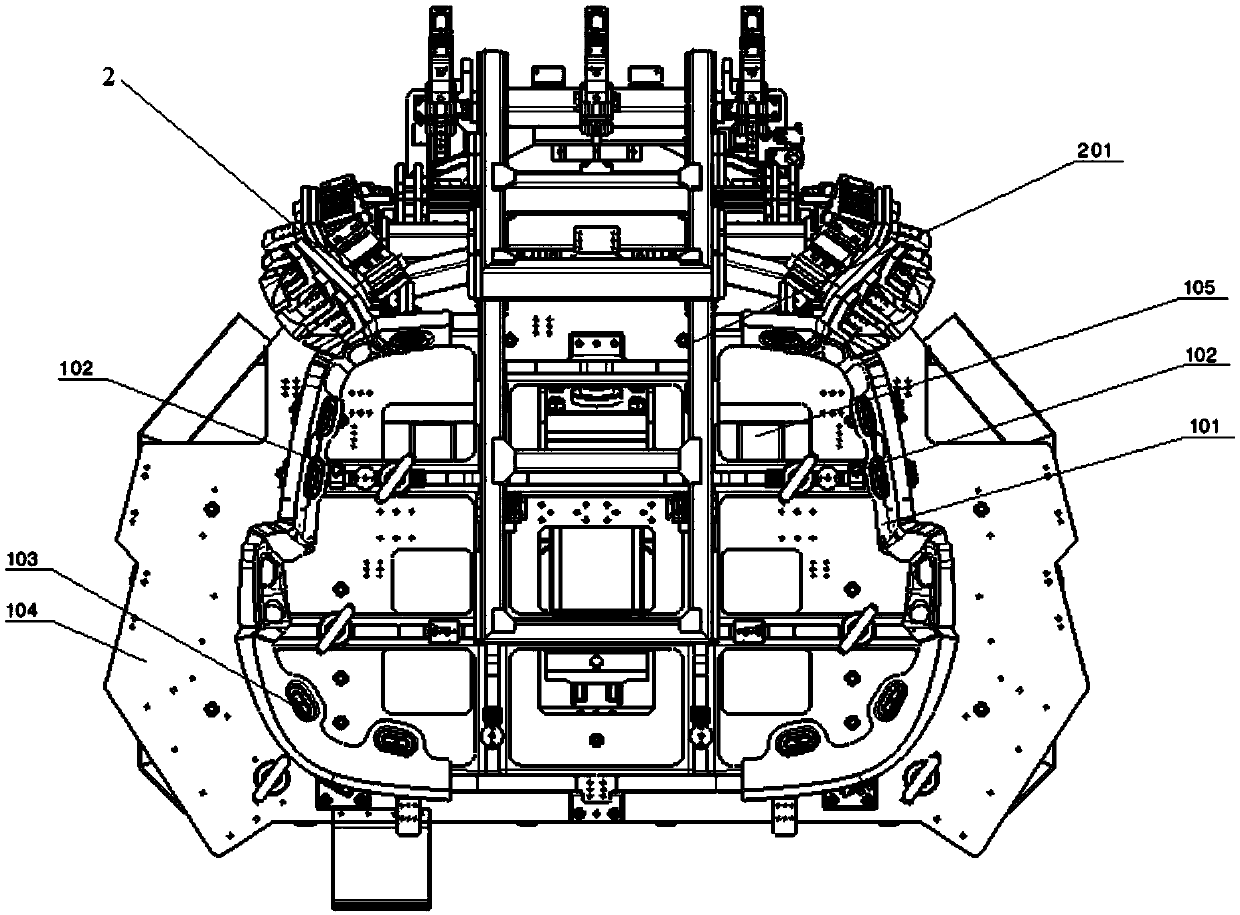

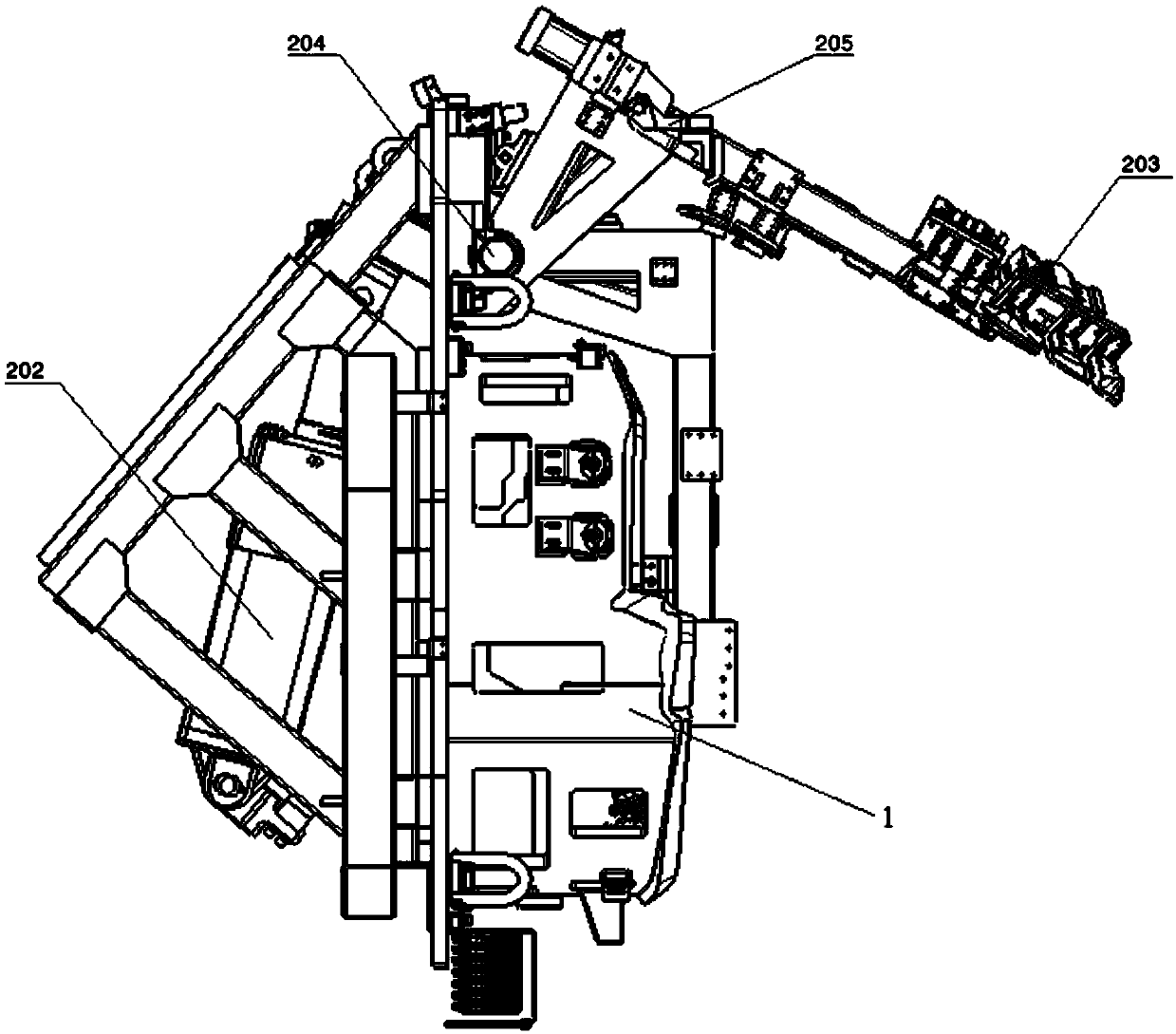

[0034] The positioning mechanism includes a tire mold clamp 1 fixed on the pre-rolling station, and a die assembly 2 arranged above the tire mold clamp 1 . The structure of tire mold fixture 1 is as figure 1 As shown, it includes a base 104 and a tire mold 101 disposed on the base 104 . The tire mold 101 is provided with a sensor 102 and a suction cup 103 for fixing a workpiece. The structure of die assembly 2 is as figure 2 As shown, it includes a frame 201 fixed to the tire mold clamp 1, a fixing piece 205 that is rotatably connected to the frame 201 through a rotating shaft 204, and a pressing block 203 that is arranged at one end of the fixing piece 205 for pressing the workpiece. The rotating shaft 204 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com