Fire control system for bulging testing of containment of nuclear power plant and configuration method of fire control system

A fire-fighting system and pressure test technology, which is applied in nuclear power generation, nuclear engineering, emergency protection devices, etc., can solve the problem that the containment pressure test of the cold-state function test cannot be completed, the cold-state function test cannot be carried out as planned, and the commissioning progress of the nuclear power plant is affected. and other issues, to achieve the effect of short equipment debugging cycle, high economy and practicability, and low additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

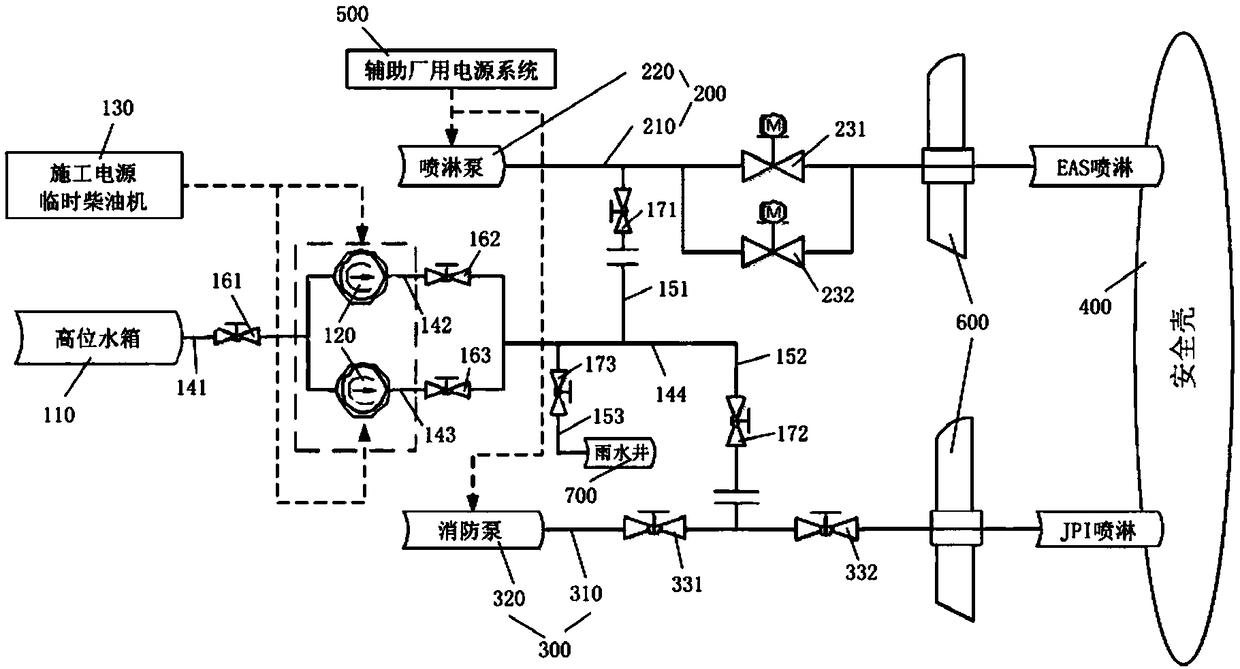

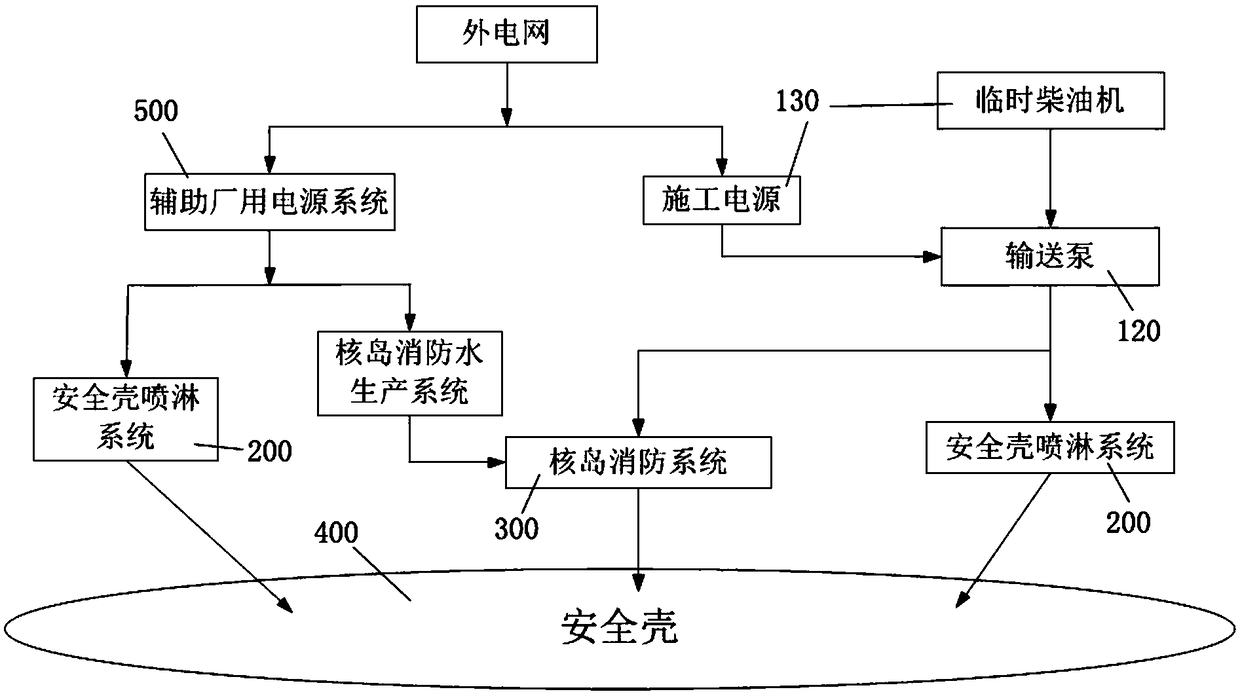

Method used

Image

Examples

Embodiment 2

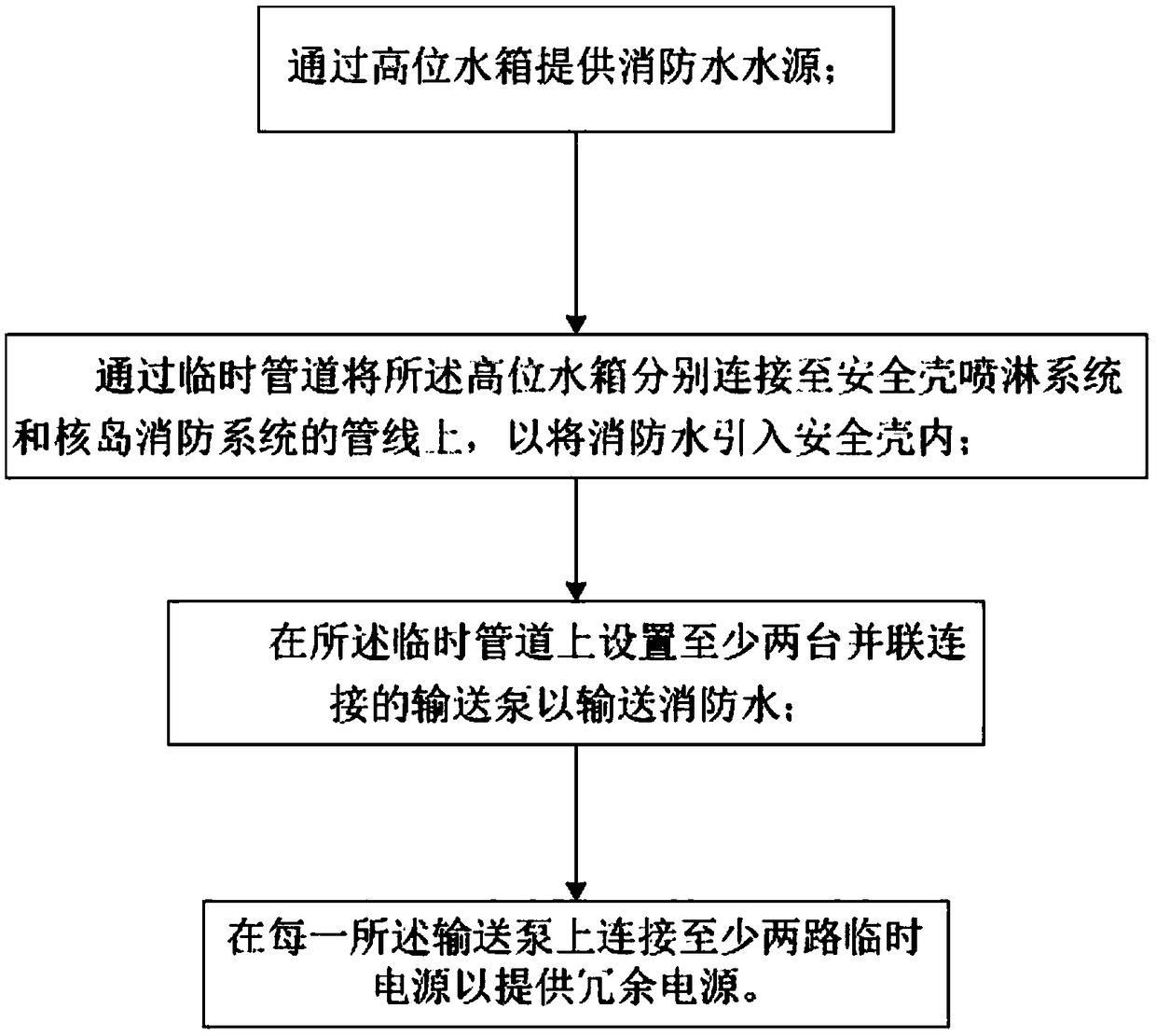

[0075] like image 3 As shown, Embodiment 2 of the present invention provides a method for configuring a fire-fighting system during a nuclear power plant containment pressure test, which is applicable to the fire-fighting system shown in Embodiment 1. The configuration method includes:

[0076] Step S1, providing a source of fire-fighting water through the high-level water tank;

[0077] Step S2, connecting the high-level water tank to the pipelines of the containment sprinkler system and the nuclear island fire protection system through temporary pipelines, so as to introduce fire-fighting water through the pipelines of the containment sprinkler system and / or nuclear island fire protection system inside the containment;

[0078] Step S3, setting at least two delivery pumps connected in parallel on the temporary pipeline to deliver fire-fighting water;

[0079] Step S4, simultaneously connecting at least two temporary power sources to each of the delivery pumps to provide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com