Mounting base for adjusting anchor chain stopper

A chain stopper and mounting seat technology, which is applied to ships and other directions, can solve the problems of long debugging period, heavy workload and labor, and difficult debugging, so as to reduce workload and labor, reduce workload, and facilitate debugging easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

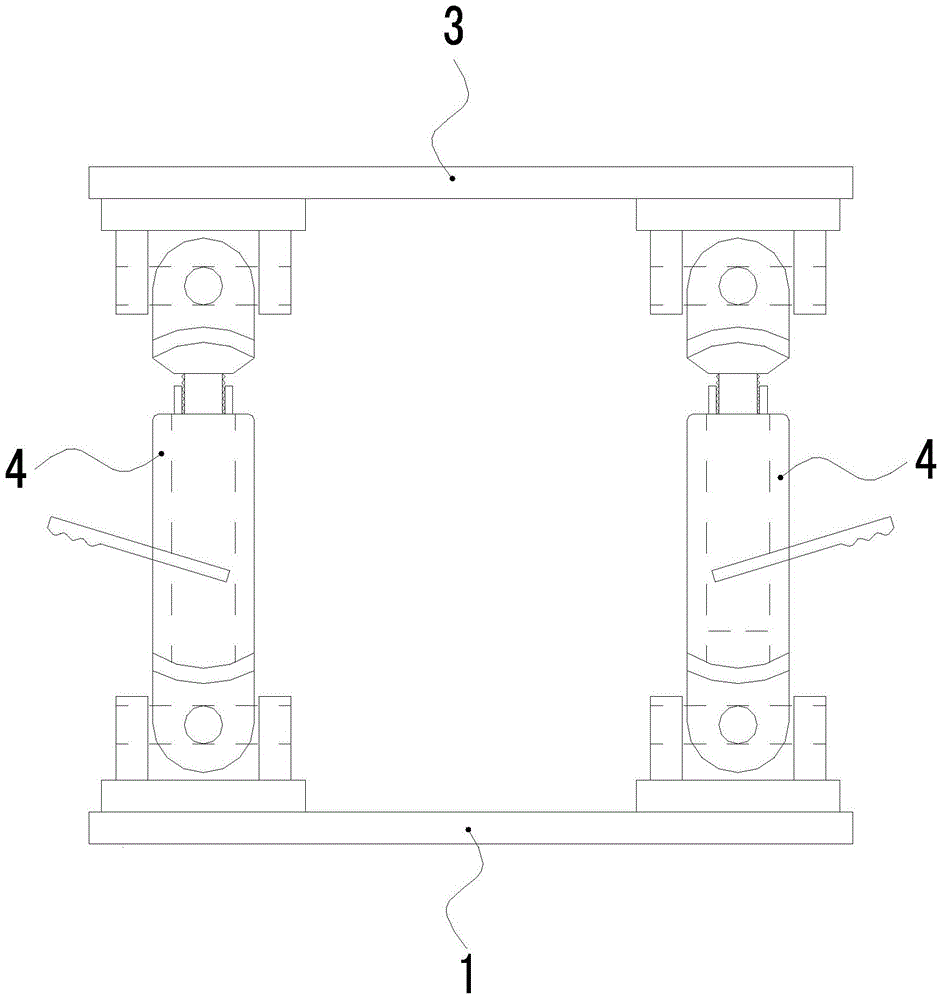

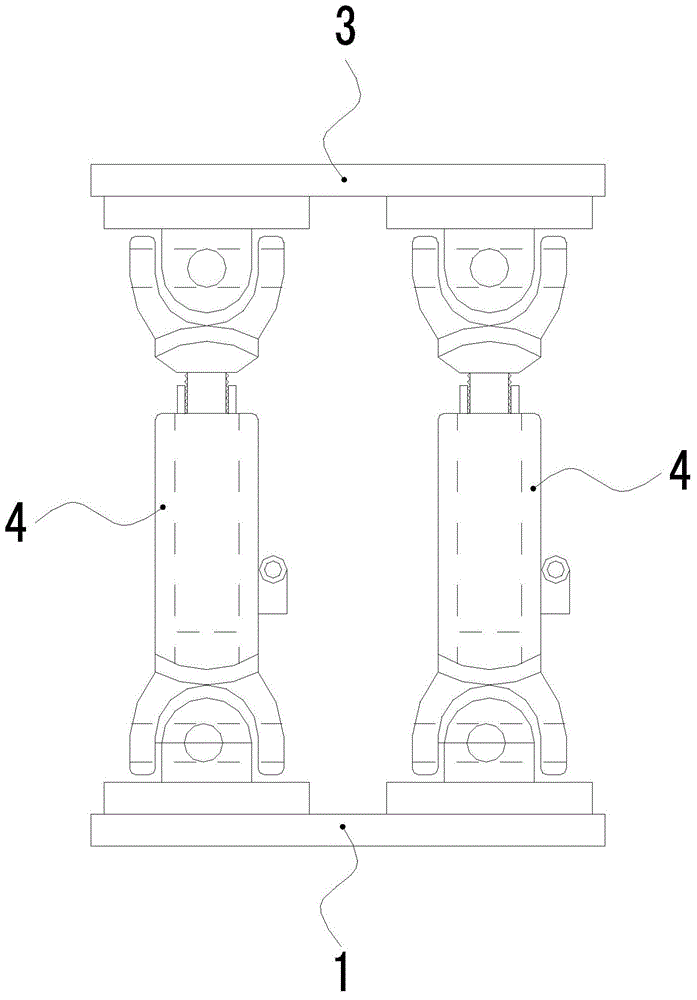

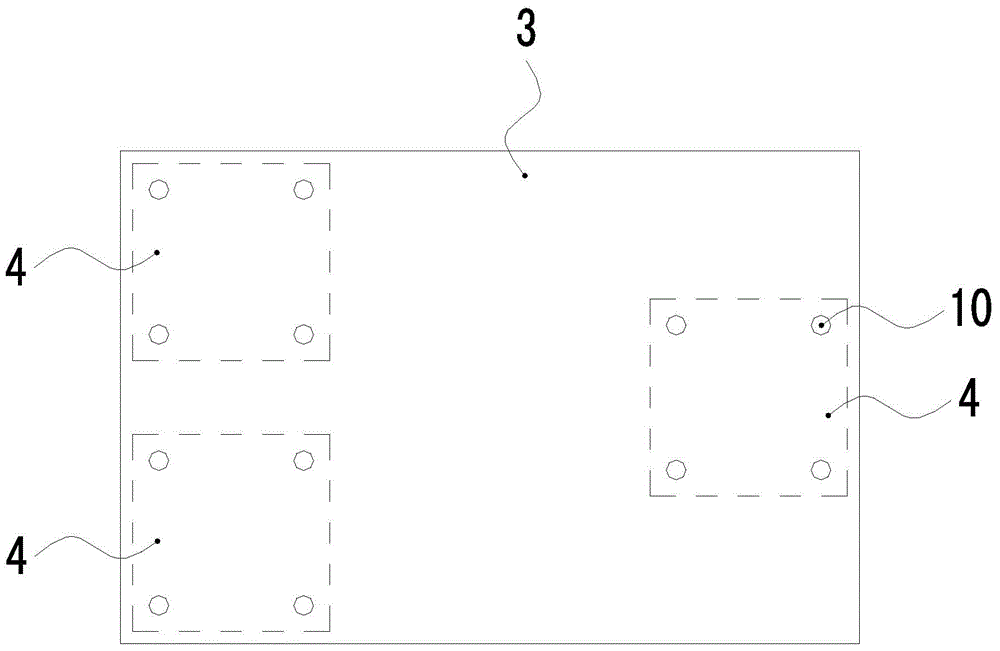

[0029] Such as Figure 1 to Figure 5 Shown is a mounting seat for debugging a chain brake, which includes a base bottom plate 1 that can be fixedly installed on the deck of a ship, and a base plate 3 for installing the chain brake 2, between the base plate 3 and the base bottom plate 1 There is a position adjustment device that can adjust the three-dimensional position of the base panel 3 in between.

[0030] The position adjustment device includes three groups of telescopic devices 4 that can be adjusted by telescoping. The three groups of telescopic devices 4 are respectively arranged on the three vertices of a triangle. The lower end of each group of telescopic devices 4 passes through the first universal joint 5 and the base plate 1. Connected, the upper ends of the telescopic devices 4 of each group are connected to the base panel 3 through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com