Boring tool for axle suspension bush of traction motor

A traction motor and tooling technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of difficult positioning and clamping, large size of traction motor, long debugging cycle, etc., to improve the scope of use and debugging. The effect of short cycle time and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure of the present invention is further described in conjunction with accompanying drawing and given embodiment:

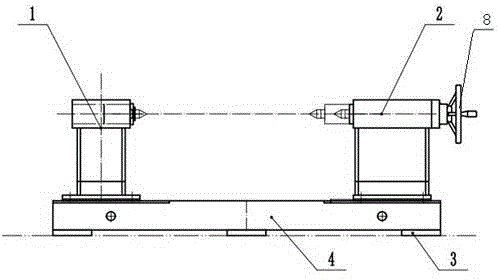

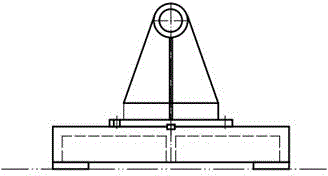

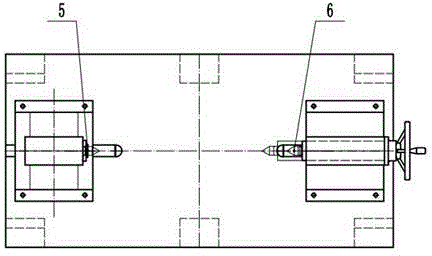

[0017] Such as figure 1 , figure 2 , image 3 As shown, a traction motor holding bearing bush boring tool, the tool includes a workbench 4, a movable tailstock I1 and a movable tailstock II2; Seat II 2 cooperates with guide rail I and guide rail II, and the axes of guide rail I and guide rail II coincide; the movable tailstock I1 and movable tailstock II2 are symmetrically arranged on the workbench 4, and pass through the slide block and The corresponding guide rails on the workbench 4 cooperate, so that the movable tailstock I1 and II2 can move toward or away from the workbench 4; the movable tailstock I1 and II2 Form a space for placing the traction motor 7 to be processed; when the movable tailstock I1 and the movable tailstock II2 move toward each other, clamp the traction motor 7 to process the traction motor bearing bush, when the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com