Multi-element high-active component deoxidizer and preparation method and application thereof

A technology with active components and high activity, applied in the field of deoxidizers, can solve the problems of low deoxidation depth, short service life, small deoxidation capacity, etc., and achieve the effects of large deoxidation capacity, long service life, and mechanical strength not easy to pulverize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh more than 400 mesh MnCO in proportion 3 、TiO 2 、CuCO 3 , high-alumina cement, as shown in Table 1, mix the above several substances with a mixer for 2 hours, take the mixture and spray distilled water, and roll it to The small balls are placed for 24h-36h, during this period every 3h-4h for water mist preservation, and then a certain amount of nitrogen is protected, then the temperature is programmed to rise to 450°C and roasted for 6 hours to decompose to make a ternary high-activity deoxidizer, and the nitrogen is protected and cooled to Set aside at room temperature. Take 240ml deoxidizer respectively In the stainless steel reactor, at 20°C and 120°C, the space velocity of hydrogen is passed for 10h -1 Restore 8h. After cooling down, under the condition of pressure 0.8Mpa, feed ethylene, and the gas phase space velocity of ethylene is 3000h -1 , the inlet oxygen content is 500ppm, and the deoxygenation depth is ≤1ppm, and the deoxygenation capacity is m...

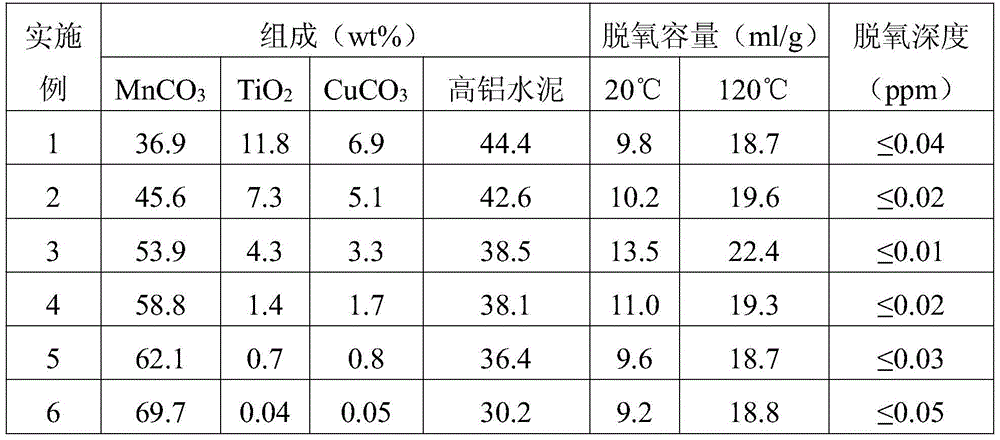

Embodiment 2~6

[0033] The preparation method and test method are the same as in Example 1, the only difference being the composition of the deoxidizer, see Table 1 for details.

[0034] The composition and evaluation result of table 1 embodiment 1-6 deoxidizer

[0035]

Embodiment 7

[0037] Weigh 58.8wt% MnCO over 400 mesh 3 , 1.4wt% TiO 2 , 1.7wt% CuCO 3 , 12.1wt% high alumina cement, 10wt% kaolin, 8wt% γ-Al 2 o 3 , 8wt% diatomaceous earth, stir the above several materials with a mixer for 2h, get the mixture sprayed with distilled water, roll to The small balls are placed for 24h-36h, during this period every 3h-4h for water mist preservation, and then a certain amount of nitrogen is protected, and then the temperature is programmed to 400°C and roasted for 6 hours to decompose to make a ternary high-activity deoxidizer. Set aside at room temperature. Take 240ml deoxidizer and put it into In the stainless steel reactor, at 20°C and 140°C, the space velocity of hydrogen is passed for 10h -1 Restore 8h. After cooling down, under the condition of pressure 0.8Mpa, feed ethylene, and the gas phase space velocity of ethylene is 3000h -1 , the inlet oxygen content is 100ppm, the deoxygenation depth is ≤0.02ppm, and the measured deoxygenation capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com