Adsorption purification method for hydrocarbon stream

A technology for purifying hydrocarbons and hydrocarbon streams, used in adsorption purification/separation, chemical instruments and methods, silicon compounds, etc. The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Contains NaY molecular sieve and CaCl 2 The preparation process of the solid adsorbent is as follows. Using alumina as the binder, according to the mass ratio of NaY molecular sieve to alumina 1:4, add a small amount of sesame powder to mix well, and then add a certain concentration of dilute nitric acid to extrude. Dry naturally, and roast in the air at 500°C for 2 hours. Grind 10-20 meshes, and dry at 400°C until the mass is no longer reduced to obtain shaped solid adsorbent precursor I, which is transferred to a desiccator for use. Prepare CaCl with a mass concentration of 10% 2 Solution I. The solid adsorbent precursor I was immersed in the above-mentioned solution I. After full immersion, filter out CaCl 2 Solution, use deionized water to wash away the remaining CaCl on the surface 2 , Get solid adsorbent II. After drying, the solid adsorbent II prepared above is dried in the air at 400° C. in a muffle furnace until the mass is no longer reduced to obtain a shape...

Embodiment 2~17

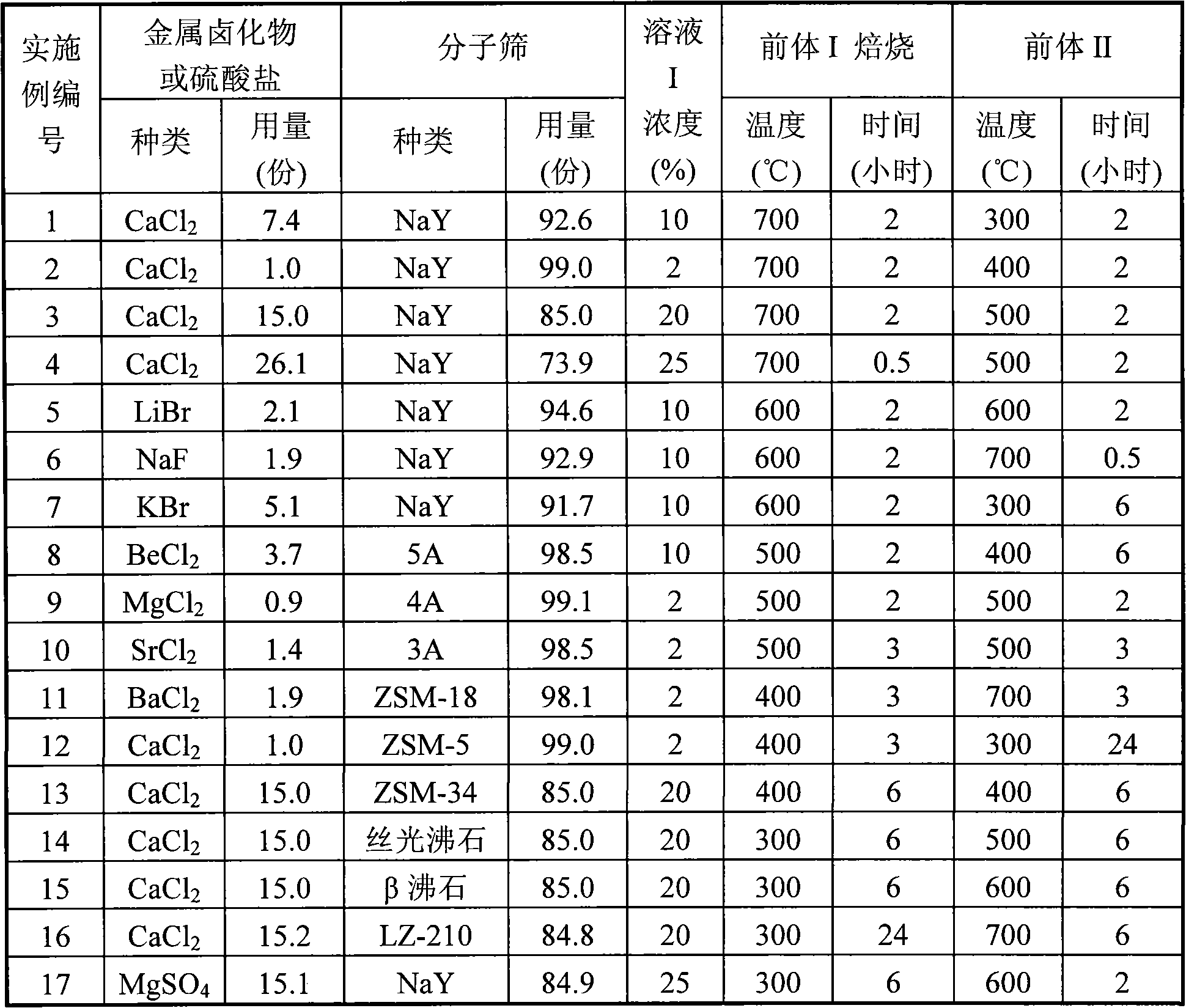

[0021] The solid adsorbent was prepared and evaluated according to the steps and conditions of Example 1. Just change the composition or preparation conditions, the changed conditions are listed in Table 1, and the evaluation results are listed in Table 2.

[0022] Table 1 Composition and preparation conditions of various adsorbents

[0023]

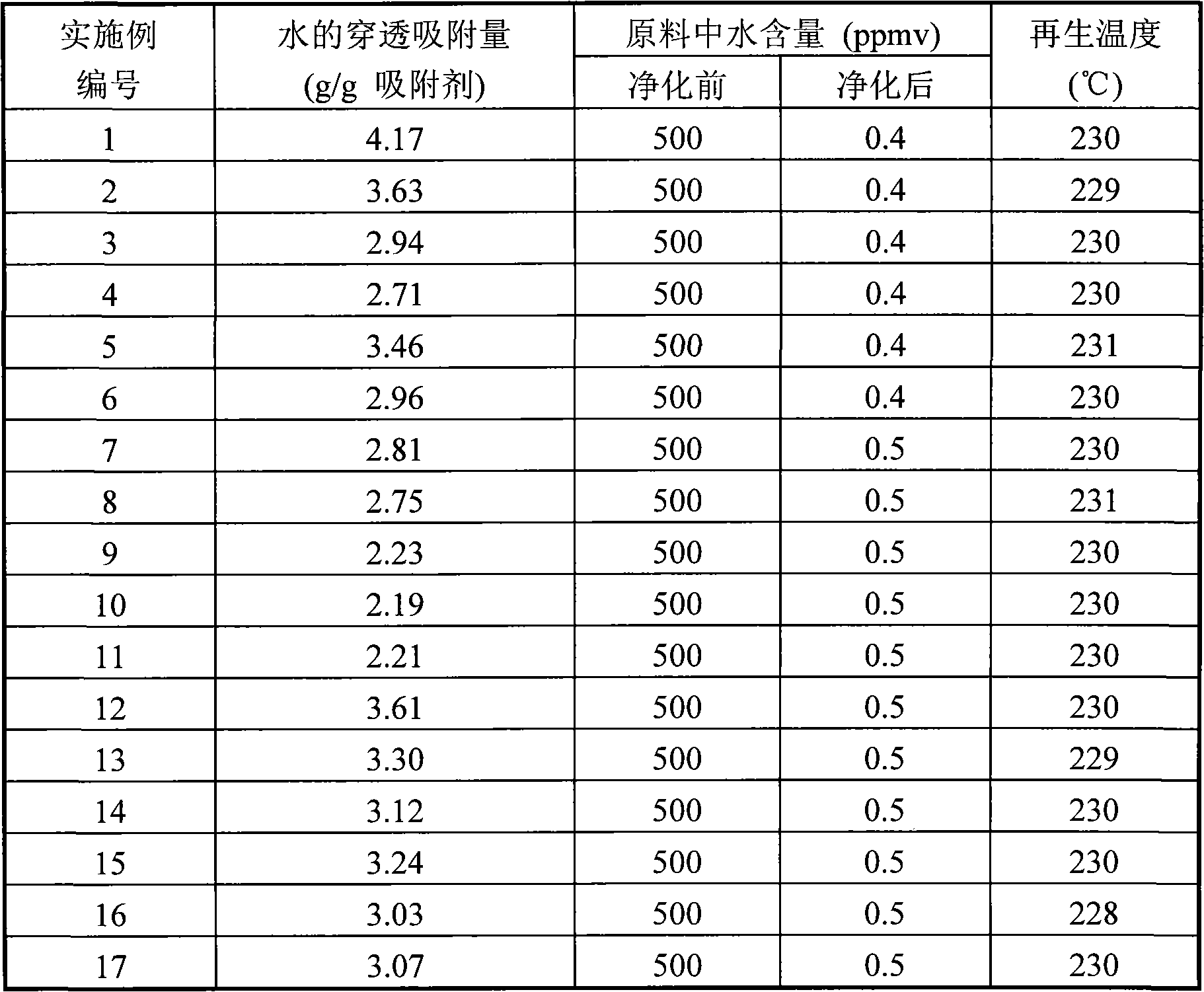

[0024] Table 2 Evaluation results of various adsorbents

[0025]

[0026] *The penetration capacity of the adsorbent is expressed by the weight of adsorbed water per gram of adsorbent.

Embodiment 18

[0028] Prepare the molecular sieve containing NaY and MgSO according to the method and steps of Example 1. 4 And CaCl 2 Solid adsorbent, but the prepared solution I contains 10% CaCl 2 Also contains 10% MgSO 4 . The obtained solid adsorbent is CaCl in weight fraction 2 Take up 7 copies, MgSO 4 It accounts for 13.2 parts, and the remainder is NaY molecular sieve. According to the same evaluation conditions as in Example 1, the through adsorption capacity of water is 4.01 g / g adsorbent, and the regeneration temperature of the adsorbent is 230°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com