Preparation method for activated carbon for desulfurization and denitrification and activated carbon for desulfurization and denitrification and application

A technology of desulfurization and denitrification and activated carbon, which is applied in the field of activated carbon, can solve the problems of reducing the denitrification rate of activated carbon, reducing the adsorption of activated carbon, complex process flow, etc., and achieve the effect of tight combination, high regeneration efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

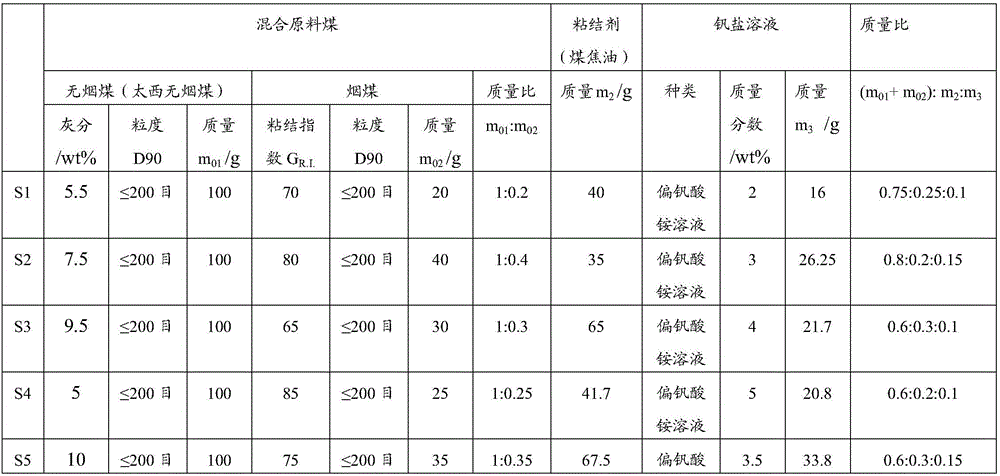

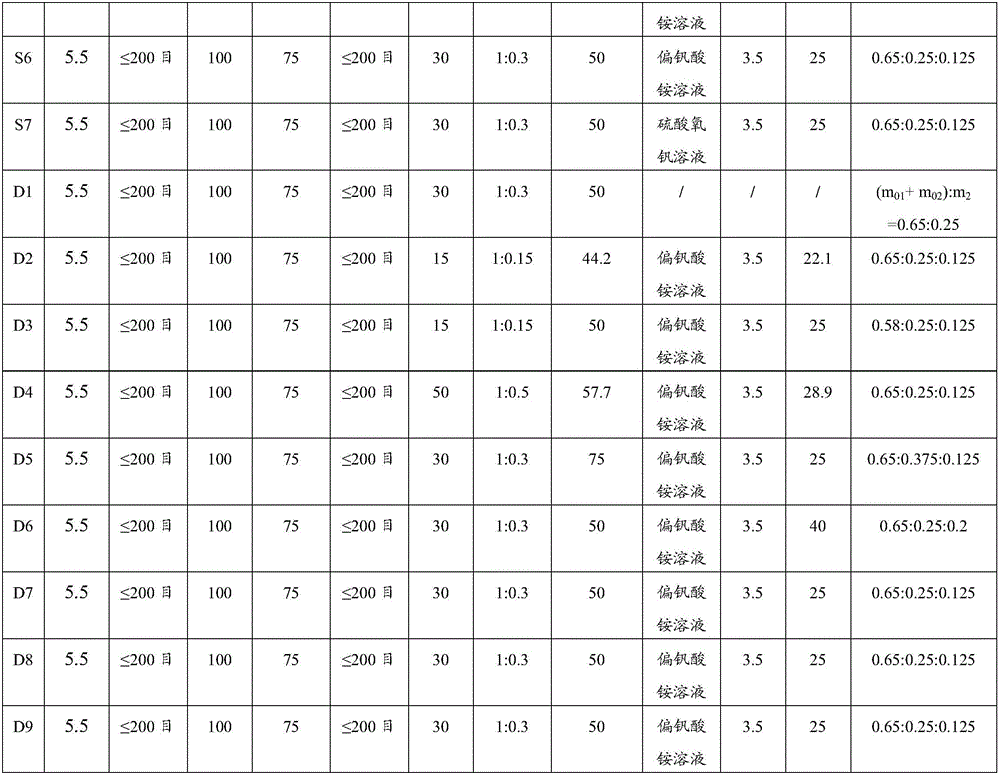

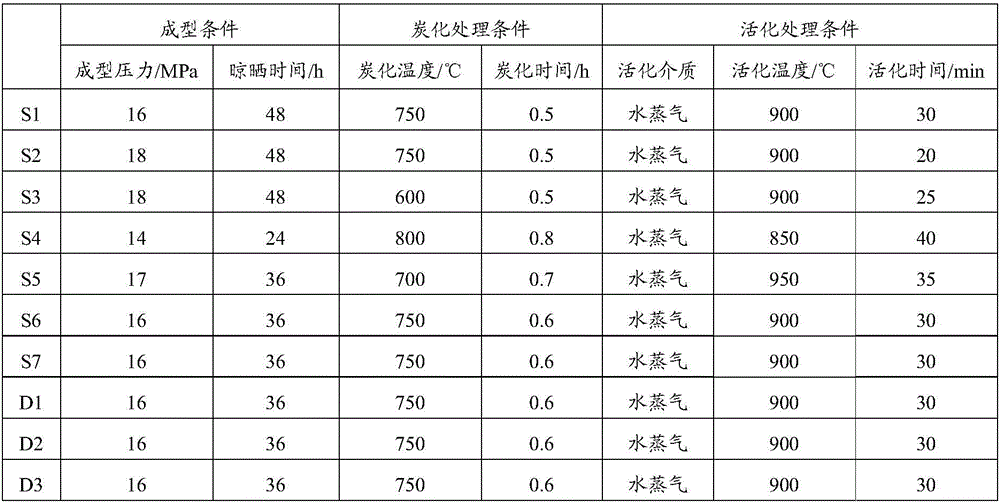

[0047] The preparation method of the activated carbon for desulfurization and denitrification of Examples 1-7 (i.e. S1-S7) and comparative examples 1-9 (i.e. D1-D9) is as follows:

[0048] (1) Mix anthracite and bituminous coal to obtain mixed raw coal;

[0049] (2) preparing vanadium salt solution;

[0050] (3) mixing the mixed raw coal obtained in step (1), the binding agent and the vanadium salt solution obtained in step (2), and stirring evenly to obtain coal paste; the binding agent is coal tar;

[0051] (4) Extrude the coal paste obtained in step (3), and dry and solidify at room temperature to obtain a material strip; then carry out carbonization treatment to the material strip to obtain carbonized material; then carry out activation treatment on the carbonized material to obtain activated carbon for desulfurization and denitrification, and use A said. Activated carbon for desulfurization and denitrification after it has been regenerated 10 times, with A 10 express. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com