Preparation and use of nano porous silica gel adsorbent material

A technology of silica gel adsorption and pore size, which is applied in chemical instruments and methods, silicon compounds, and other chemical processes, can solve the problems of unstable performance of silica gel core, corrosion of surrounding metal equipment, and decrease of silica gel specific surface area, etc., to achieve material saving Significant energy saving effect, heat saving, fast adsorption/desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

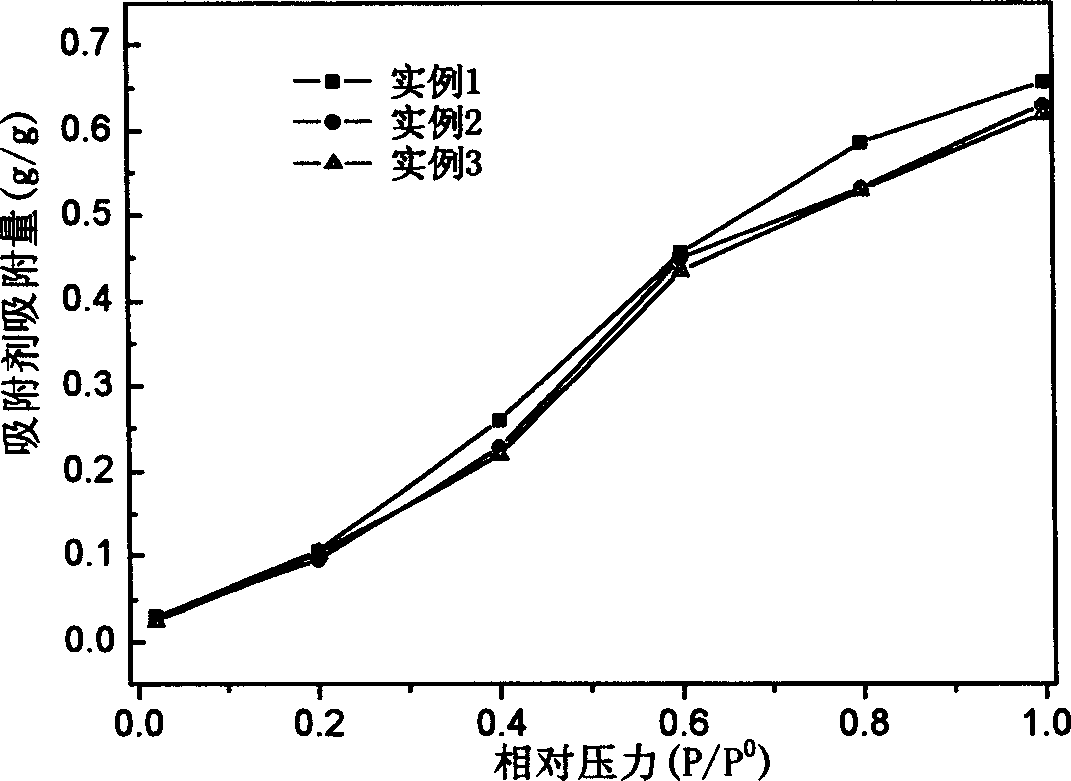

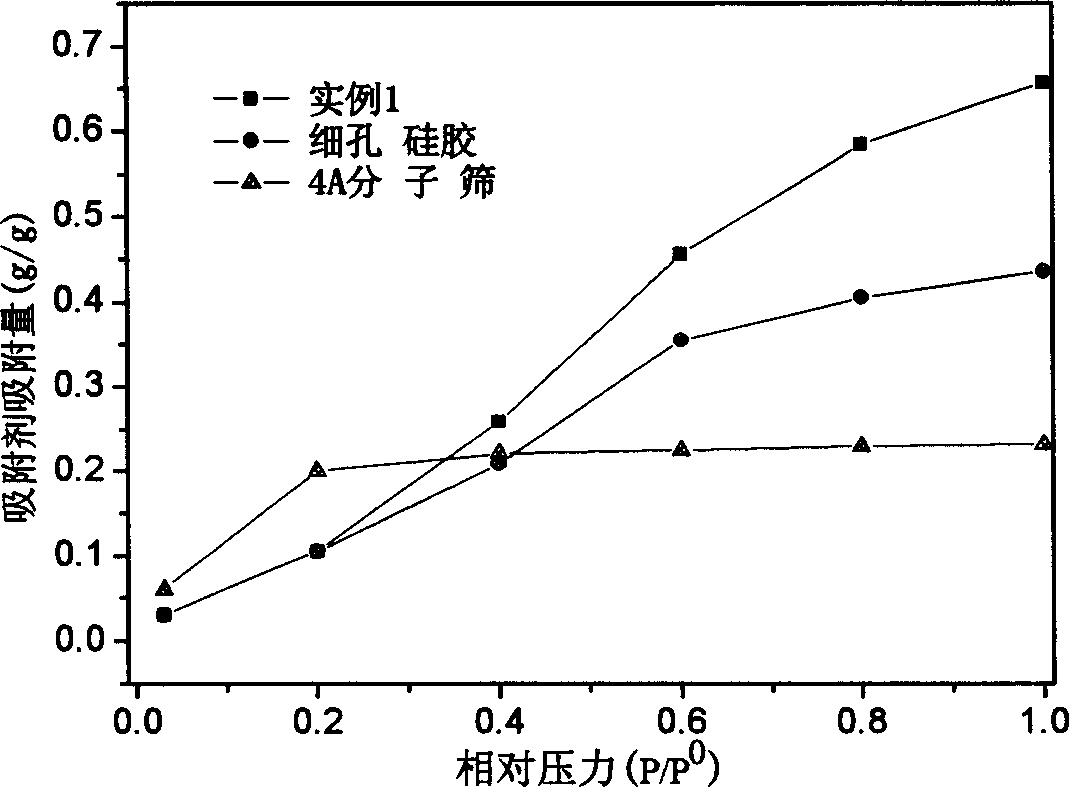

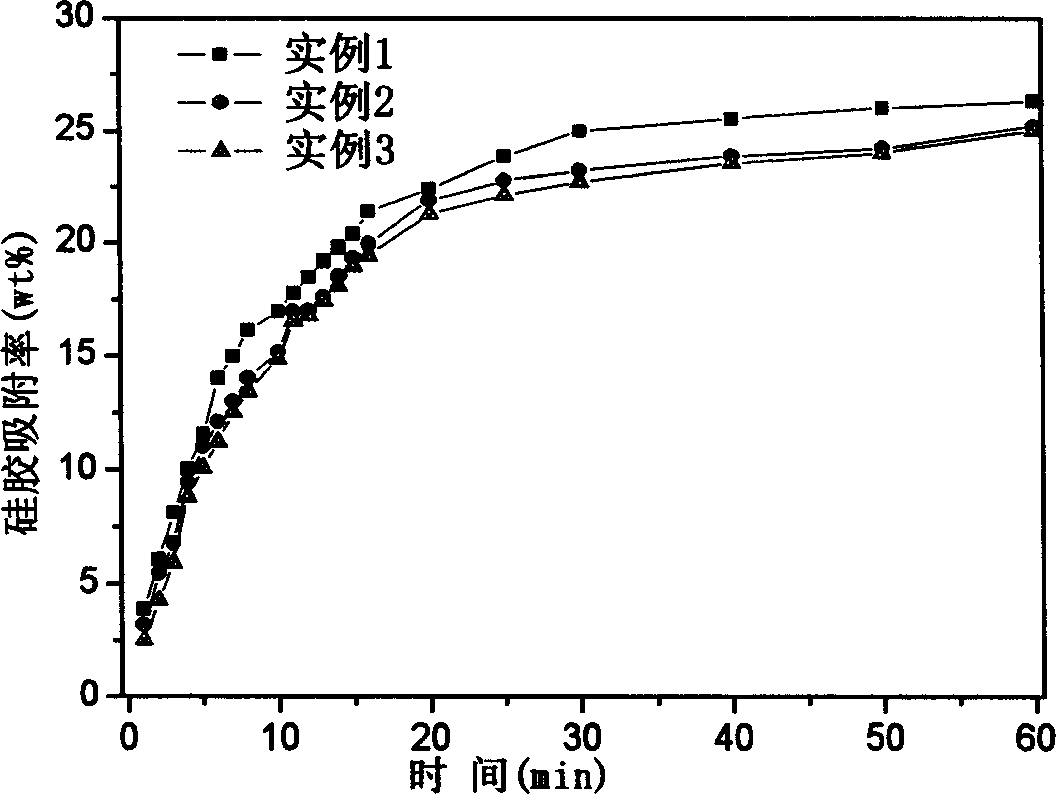

Embodiment 1

[0022] (1) At room temperature, in a 200L round plastic container, add 120L of water, then add 40Kg of water glass with a modulus of 3.0, stir evenly, and put the formed honeycomb core made of inorganic fiber paper (500mm× 200mm) into it for 12 hours to fully infiltrate it, take it out to dry, then dry at 60°C for 18 hours at low temperature, and cool to room temperature; (2) Weigh 25Kg of anhydrous calcium chloride and dissolve it in 125L of water, Immerse the above-mentioned honeycomb core in it, react for 12 hours, take it out and dry it in the air, then place it in an oven to dry at 60°C for 24 hours, and cool to room temperature; (3) measure 10L of industrial concentrated hydrochloric acid and dilute it to 160L, Immerse the rotating core in it, take it out after 20 hours and rinse it with water until the pH is neutral, dry it in a 40°C constant temperature drying oven for 24 hours, then place the rotating core in an intelligent constant temperature sintering furnace, and ...

Embodiment 2

[0024] (1) At room temperature, in a 200L round plastic container, add 100L of water, then add 40Kg of water glass with a modulus of 3.0, stir evenly, and put the formed honeycomb core made of inorganic fiber paper (500mm× 200mm) into it for 12 hours to fully infiltrate it, take it out and dry it in the air, then dry it at a low temperature at 60°C for 18 hours, and cool to room temperature; (2) Weigh 30Kg of anhydrous calcium chloride and dissolve it in 120L of water, and The above-mentioned honeycomb core was immersed in it, and after 12 hours of reaction, it was taken out to dry, and then placed in an oven to dry at 60°C for 24 hours, and cooled to room temperature; (3) Measure 10L of industrial concentrated hydrochloric acid and dilute it to 160L, and the Immerse the core in it, take it out after 20 hours, wash it with water until the pH is neutral, dry it in a constant temperature drying oven at 40°C for 24 hours, then place the core in an intelligent constant temperature...

Embodiment 3

[0026] (1) At room temperature, in a 200L circular plastic container, add 120L of water, then add 30Kg of water glass with a modulus of 3.0, stir evenly, and put the formed honeycomb core made of inorganic fiber paper (500mm× 200mm) into it for 12 hours to fully infiltrate it, take it out and dry it in the air, then dry it at 60°C for 18 hours, and cool to room temperature; (2) Weigh 20Kg of anhydrous calcium chloride and dissolve it in 140L of water, and dissolve the above Immerse the honeycomb rotor core in it, take it out after 12 hours to dry it, then place it in an oven to dry at 60°C for 24 hours, and cool to room temperature; (3) Measure 9L of industrial concentrated hydrochloric acid and dilute it to 160L, and immerse the honeycomb rotor core Among them, take it out after 20 hours and wash it with water until the pH is neutral, dry it in a 40°C constant temperature drying oven for 24 hours, then place the rotor in an intelligent constant temperature sintering furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com