Phase change absorbent for capturing CO2 in waste gas

An absorbent and waste gas technology, which is applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of weak anti-oxidative degradation ability, low decarbonization ability of absorbent and high regeneration temperature, so as to improve its own performance. The effect of stability, increasing absorption capacity, and reducing energy consumption for regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

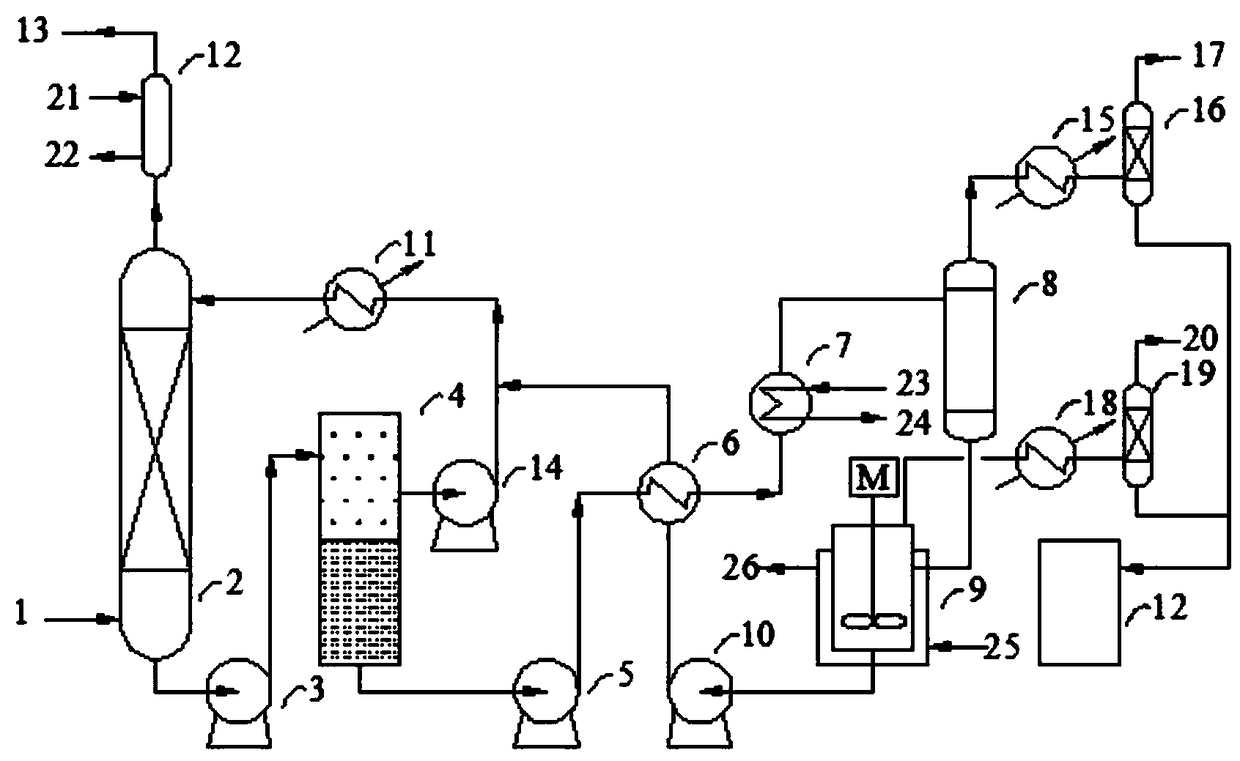

Method used

Image

Examples

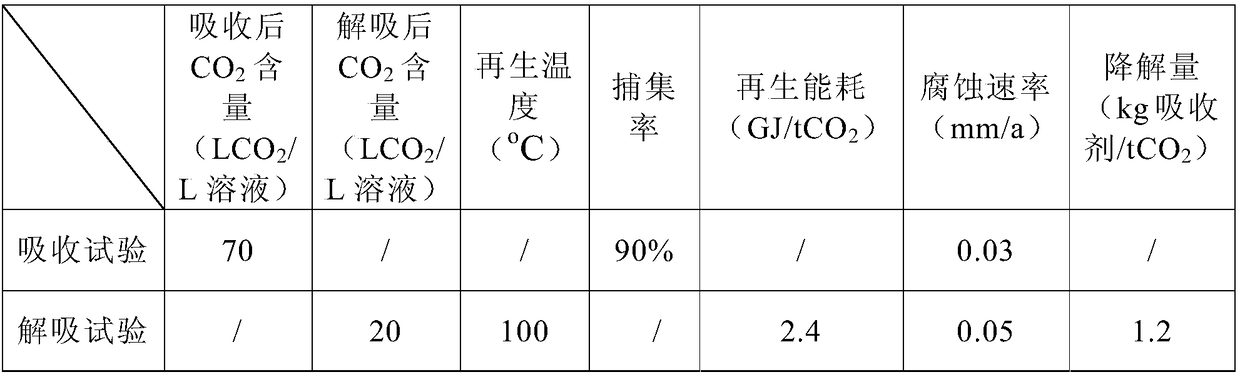

Embodiment 1

[0035] Prepare 300L to capture CO in exhaust gas 2 The phase change absorbent, wherein, the content of alcohol amine absorbent is 20wt%, is composed of: pentanediolamine 10wt%, 4-amino-1-butanol 5wt%, N,N-diethylethanolamine 5wt% ; The content of amine absorbent is 8wt%, composed of: n-butylamine 4wt%, di-sec-butylamine 4wt%; the content of nanoparticles is 0.5wt%, composed of: TiO 2 0.25wt%, ZnO 0.25wt%, particle size D50 is 50nm, specific surface area is 1m 2 / g; The content of corrosion inhibitor is 0.1wt%, is composed of: potassium chromate 0.04wt%, potassium dichromate 0.06wt%; The content of antioxidant is 0.1wt%, is composed of: sodium potassium tartrate 0.05wt%, Sodium thiosulfate 0.05wt%; defoamer content 0.02wt%, composition: polyether 0.02wt%; water content 71.28wt%.

[0036] Test process: the temperature is 40°C, the gas phase CO 2 Partial pressure of 0.1MPa containing CO 2 , O 2 and N 2 The mixed gas (simulated flue gas component) input is filled with the CO...

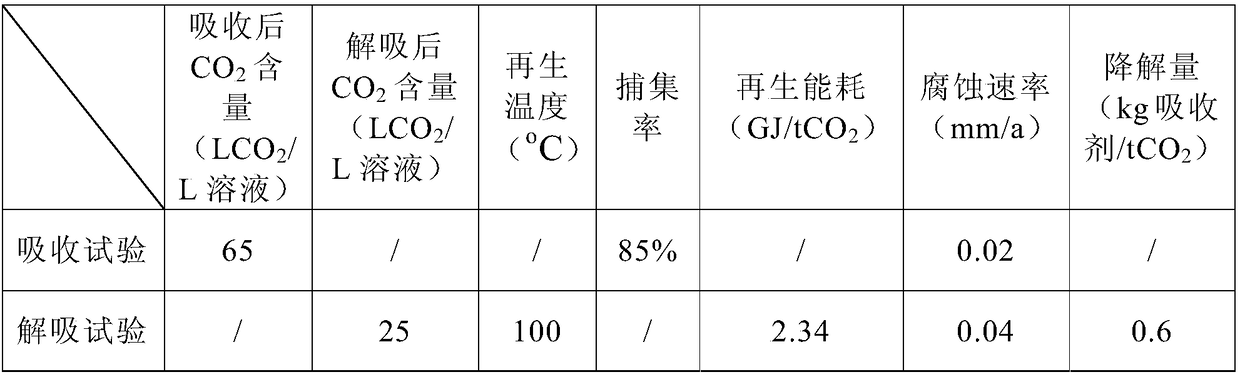

Embodiment 2

[0040] Prepare 300L to capture CO in exhaust gas 2 The phase change absorbent, wherein, the content of alcohol amine absorbent is 20wt%, is composed of: ethanolamine 10wt%, diethylethanolamine 5wt%, N-methyldiethanolamine 5wt%; The content of amine absorbent is 5wt% %, composed of: isopropylamine 2wt%, n-propanolamine 3wt%; the content of nanoparticles is 0.5wt%, composed of: TiO2 0.25wt%, ZnO 0.25wt%, particle diameter D50 is 50nm, specific surface area is 1m 2 / g; the content of corrosion inhibitor is 0.2wt%, and consists of: potassium chromate 0.1wt%, sodium phosphate 0.1wt%; the content of antioxidant is 0.2wt%, is composed of: sodium metavanadate 0.1wt%, sodium phosphate Sodium bisulfate 0.1wt%; defoamer content 0.1wt% composition: simethicone oil 0.1wt%; water content 74wt%.

[0041] Test process: the temperature is 40°C, the gas phase CO 2 Partial pressure of 0.2MPa containing CO 2 , O 2 and N 2 The mixed gas (composition of simulated flue gas) is input and filled ...

Embodiment 3

[0045] Prepare 300L to capture CO in exhaust gas 2 The phase-change absorbent, wherein, the content of alcohol amine absorbent is 15wt%, is composed of: diethylethanolamine 5wt%, 2-ethyl-2-hydroxymethyl-1,3-propanediol 5wt%, 3- Amino-1-propanol 5wt%; the content of amine absorbent is 10wt%, composed of: n-pentylamine 5wt%, diethylamine 5wt%; the content of nanoparticles is 0.1wt%, composed of: MgO 0.05wt% , CuO0.05wt%, particle size D50 is 50nm, specific surface area is 1m 2 / g; the content of corrosion inhibitor is 0.02wt% and consists of: imidazoline 0.01wt%, quaternary ammonium salt 0.01wt%; the content of antioxidant is 0.2wt%, consists of: sodium metabisulfite 0.1wt%, thiosulfuric acid 0.1wt% of sodium; 0.08wt% of defoaming agent, composed of: 0.08wt% of polyether modified silicon; 74.6wt% of water.

[0046] Test process: the temperature is 40°C, the gas phase CO 2 Partial pressure of 0.4MPa containing CO 2 , O 2 and N 2 The mixed gas (composition of simulated flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com