Regeneration system of dehumidifying solution for moist air

A technology of solution regeneration and humid air, which is applied in the field of humid air dehumidification, can solve problems such as impracticability and difficulty in solution regeneration, and achieve the effects of improving regeneration efficiency, obvious energy saving effect, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

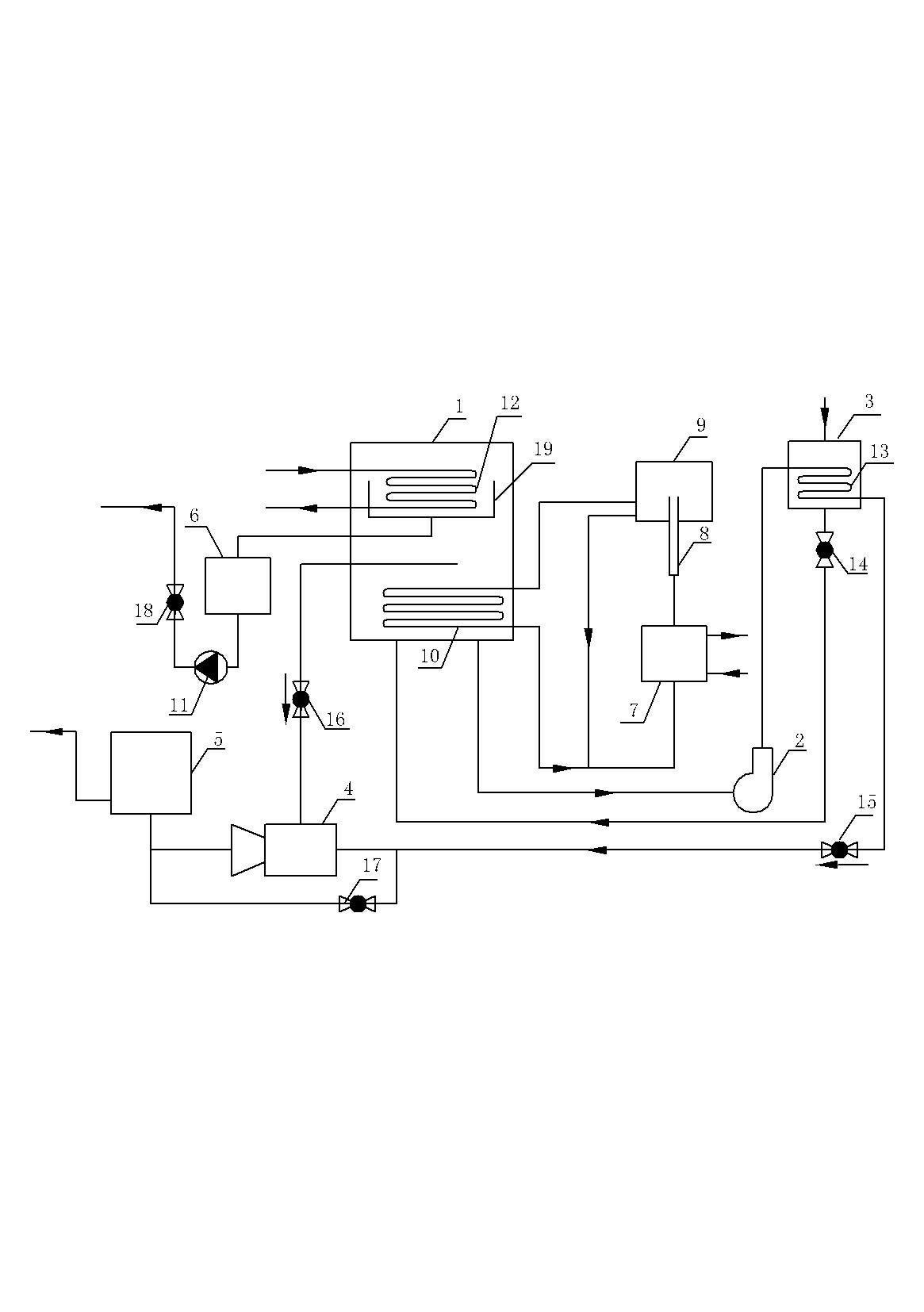

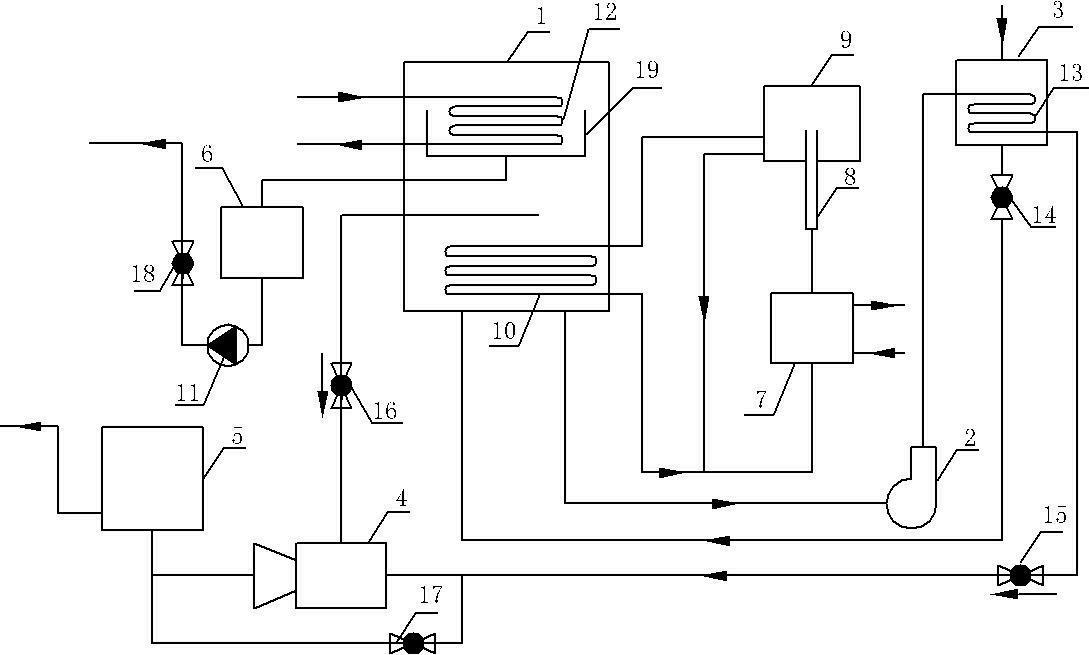

[0015] An embodiment of a wet air dehumidification solution regeneration system, in figure 1 Among them, the dilute solution storage tank 3 of the wet air dehumidification solution regeneration system is provided with a solution heat exchange tube 13, and the generator 1 is provided with a heating coil 10 and a condensation coil 12, and the heating coil 10 is located in the generator 1 In the lower part, the condensation coil 12 is located on the upper part of the generator 1 . A condensate pan 19 is also fixed inside the generator 1, and the condensate coil 12 is located in the condensate pan 19. A condensate discharge port is provided on the condensate pan 19, and a condensate storage tank is connected to the condensate discharge port. 6. The outlet of the condensate storage tank 6 is connected to the inlet of the condensate pump 11 , and the outlet of the condensate pump 11 discharges the condensate through the second switch control valve 18 . The liquid inlet of the dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com