Dehumidifier

A dehumidifier and runner technology, applied in the field of low-temperature regenerative low dew point energy-saving dehumidifiers, can solve the problems of high cost of dehumidifiers and high energy consumption of dehumidifiers, and achieve the goal of alleviating the shortage of electricity, realizing energy supply and reducing emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

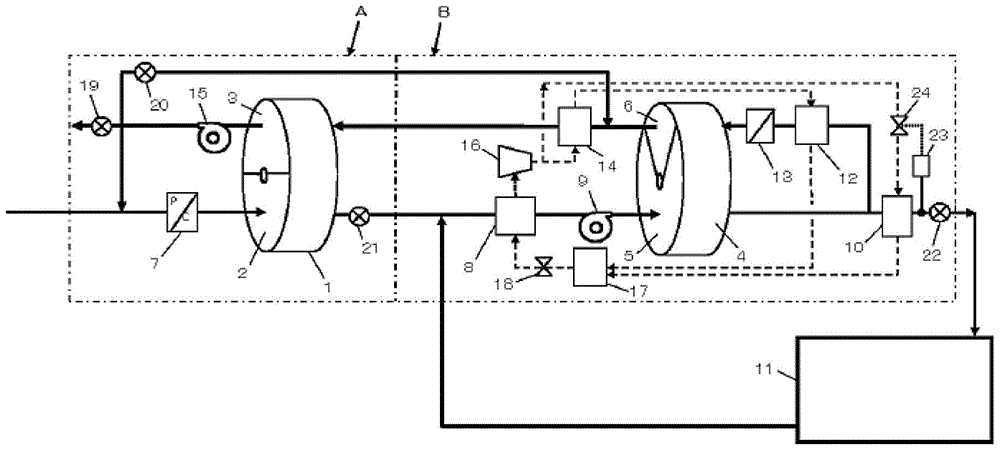

[0046] figure 1 It is a schematic flow diagram of one of the embodiments of the present invention. The number 1 in the figure is the first-stage dehumidification rotor, which is divided into two areas: treatment area 2 and regeneration area 3, 4 is the second-stage dehumidification rotor, and the second-stage dehumidification rotor is also divided It is divided into two areas: treatment area 5 and regeneration area 6.

[0047] 7 is the first cooler, which is used to cool the outdoor fresh air OA, through the first cooler, the outdoor fresh air is cooled to below its dew point temperature, so that the water vapor contained in it is condensed into condensed water and discharged to The dehumidifier is installed outside, so as to achieve the pretreatment purpose of cooling and dehumidifying the outdoor fresh air. The air cooled and dehumidified by the first cooler is sent to the treatment area 2 of the first-stage dehumidification wheel 1 by the suction force of the treatment fa...

Embodiment 2

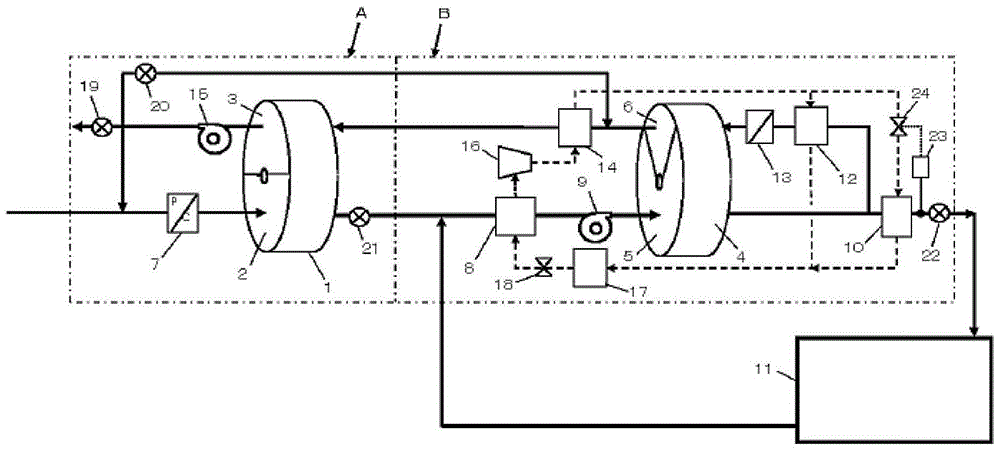

[0061] figure 2 It is the figure of Example 2 of this invention. Due to the process of dehumidifier installation and figure 1 The ones shown are basically the same, and the descriptions of the repeated parts are omitted. exist figure 1 In the embodiment, the condenser serving as the fourth heater 14 is connected in series with the refrigerant circulating in the condenser serving as the second heater 12, and then formed with the refrigerant circulating in the condenser serving as the first heater 10. Parallel state. while in figure 2 In the shown embodiment, the flow conditions of the refrigerant in the condenser as the first heater 10 and the refrigerant in the condenser as the second heater 12 are in parallel state, and then with the condenser as the fourth heater 14 The refrigerant flow in the system forms a series state. If it is not possible to use the dehumidifier due to the location where the dehumidifier is installed figure 1 The implementation shown can be use...

Embodiment 3

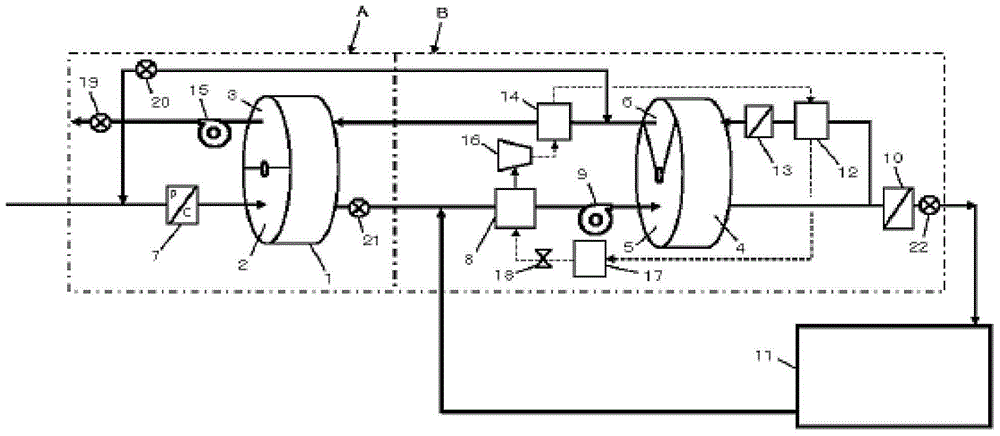

[0068] image 3 It is a schematic flow chart of Embodiment 3 of the present invention. The first-stage desiccant wheel 1 is divided into two areas: a treatment area 2 and a regeneration area 3 , and the second-stage dehumidification wheel 4 is also divided into two areas: a treatment area 5 and a regeneration area 6 .

[0069] Cool the outdoor fresh air OA to below its dew point temperature through the first cooler 7, so that the water vapor contained in it is condensed into condensed water and discharged to the outside of the dehumidifier device, so as to achieve the pretreatment of cooling and dehumidifying the outdoor fresh air Purpose. The air cooled and dehumidified by the first cooler 7 is sent to the treatment area 2 of the first-stage dehumidification wheel 1 by the suction force of the treatment fan 9, and the air after passing through the treatment area 2 is combined with the return air returned from the drying room After the air RA is mixed, it enters the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com