Double phase absorption system for removing CO2 from flue gas

A flue gas and system technology, applied in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult regeneration, achieve fast absorption rate, low regeneration energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

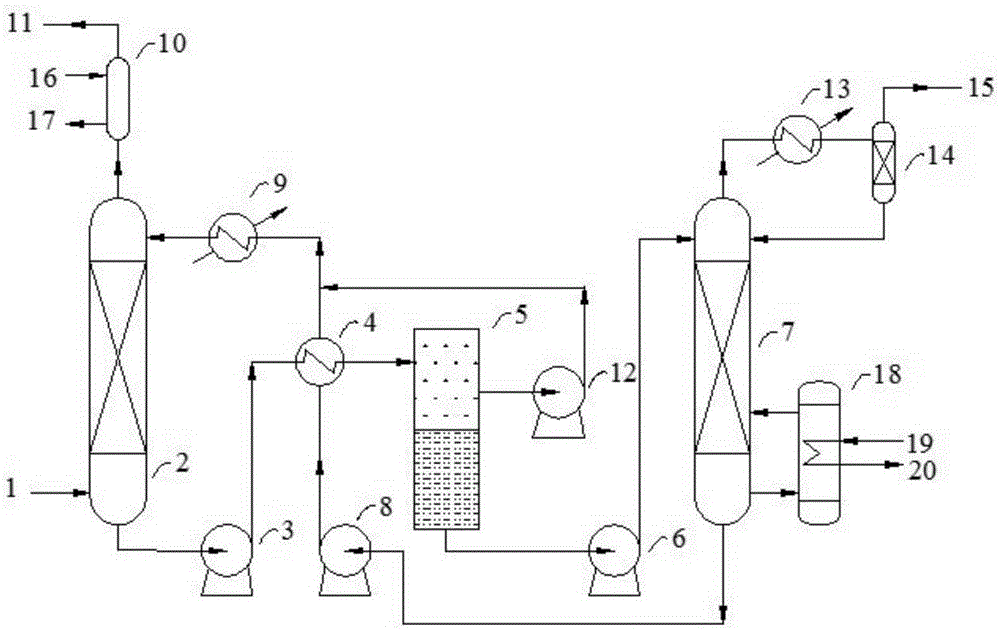

Image

Examples

Embodiment 1

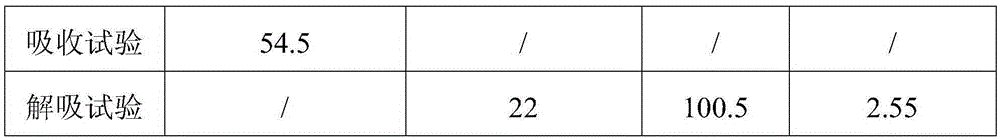

[0024] Prepare 300L composite absorbent, wherein the composition and content of each component are as follows: the content of diethylethanolamine in the alcohol amine absorbent component is 13.5wt%, the content of diphenylamine in the amine absorbent component is 8wt%, and the activator The contents of pentaethylenehexamine and hexaethyleneheptamine are 2wt% and 1.5wt% respectively; The content is 33wt%.

[0025] The test process is: refer to figure 1 , the temperature is 40 °C, the gas phase CO 2 The partial pressure is 0.1MPa, the volume fraction is 15% containing CO 2 , O 2 and N 2 The mixed gas (simulated flue gas component) is input into the 1000Nm gas filled with the above composite absorbent 3 / dCO 2 Capture continuous test experimental device, in which the absorption tower has a diameter of 200mm, a tower height of 16m, and a packing layer of 10m; a desorption tower has a diameter of 150mm, a tower height of 12m, and a packing layer of 8m; the solution circulatio...

Embodiment 2

[0030] Prepare 300L composite absorbent, wherein the composition and content of each component are as follows: the content of 2-ethyl-2-hydroxymethyl-1,3-propanediol in the alcohol amine absorbent component is 15wt%, and the amine absorbent component The content of di-sec-butylamine is 6.5wt%, the content of activator components pentaethylenehexamine and hexaethyleneheptamine is 2wt%, 1.5wt% respectively, and the content of consumption reducer component pimelic acid is 2wt%. The content of water is 40 wt%, and the content of n-butanol, an organic solvent component, is 33 wt%.

[0031] The test process is the same as in Example 1, and the relevant data results are shown in Table 2.

[0032] Table 2 Composite absorbent absorption, desorption test results

[0033]

Embodiment 3

[0035] Prepare 300L composite absorbent, wherein the composition and content of each component are as follows: the content of diethanolamine in the alcohol amine absorbent component is 15wt%, and the content of 3-methylaminopropylamine in the amine absorbent component is 6.5wt%. The contents of the agent component 2-methylpiperidine and aminoethylpiperazine are respectively 2wt%, 1.5wt%, the content of the consumption reducing agent component pimelic acid is 2wt%, the content of water is 40wt%, and the organic solvent is The content of butanol was 33% by weight.

[0036] The test process is the same as in Example 1, and the relevant data results are shown in Table 3.

[0037] Table 3 Composite absorbent absorption, desorption test results

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com