Aluminium modified silica-gel adsorbent material and its preparing process

A technology of silica gel adsorption and aluminum modification, which is applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of enhanced mechanical strength, enhanced heat resistance, and affecting service life, and achieves improved mechanical strength and heat resistance. Enhanced, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

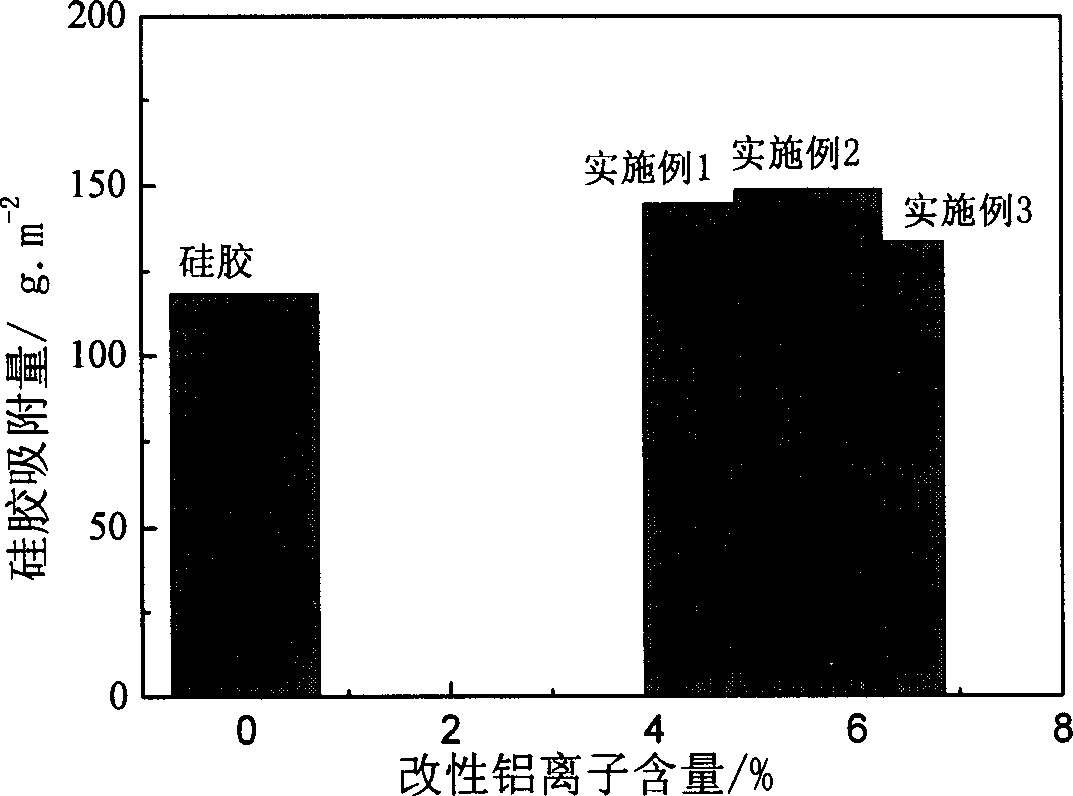

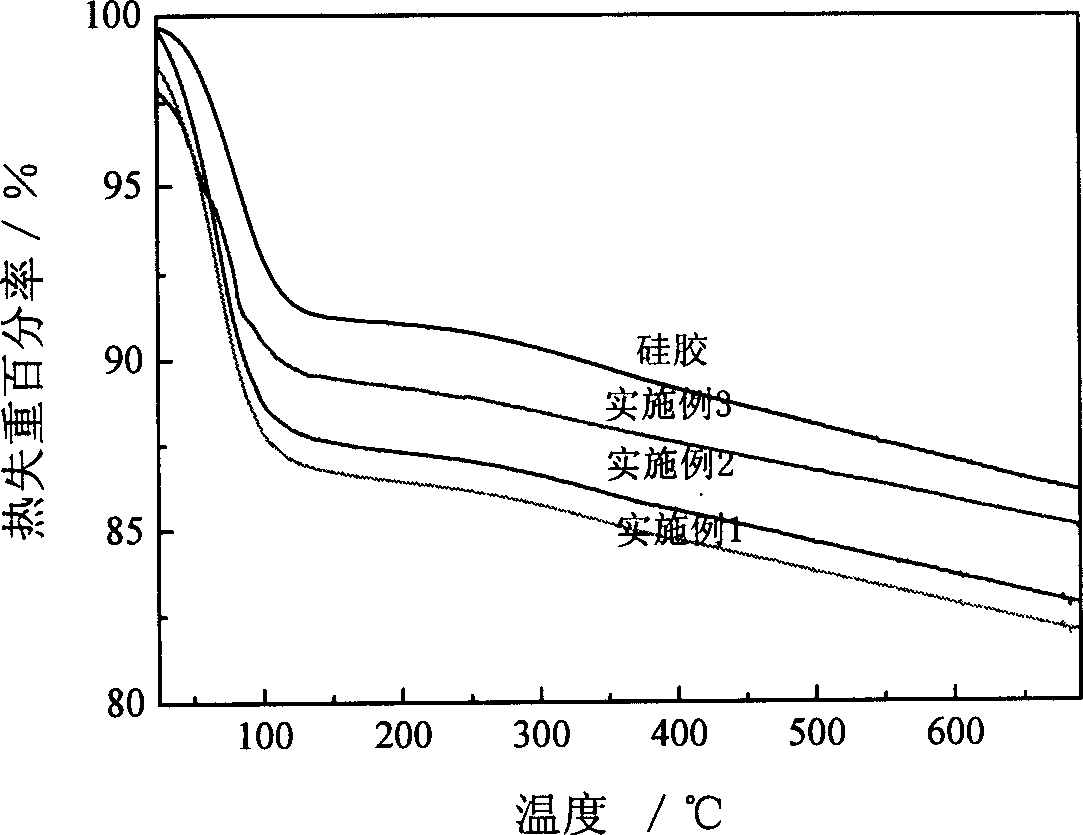

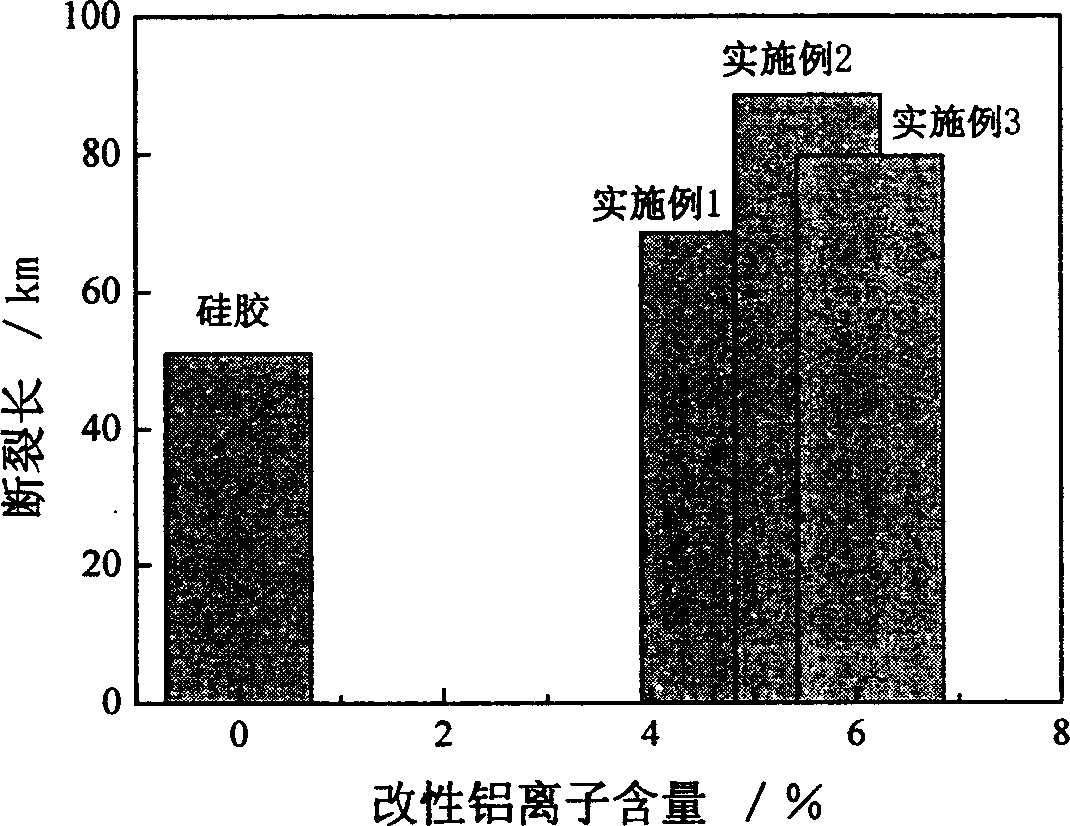

Embodiment 1

[0025] The inventive method comprises the following specific steps: (1) at room temperature, in a 250L circular plastic container, add 100L of water, then add 80Kg of water glass with a modulus of 3.0, stir evenly, and heat-roll the molded glass of inorganic fiber paper Put the honeycomb core (300mm×150mm) into it and soak it for 3 hours, make it fully soaked, take it out and dry it in the air, then dry it at 60°C for 18 hours, and cool it to room temperature; (2) Weigh 30Kg of crystalline sulfuric acid Dissolve aluminum in 120L of water, add acetic acid to adjust the pH value of the solution to 1.0, raise the temperature to 50°C, immerse the above-mentioned honeycomb core in it under strong stirring, and strictly control the reaction under the condition that the pH value of the solution is 1.0 (with As the reaction continues, the pH value of the solution increases, and it is necessary to add acid solution from time to time, the same below), take it out after 12 hours, rinse w...

Embodiment 2

[0027]The inventive method comprises the following specific steps: (1) at room temperature, in a 250L circular plastic container, add 100L of water, then add 100Kg of water glass with a modulus of 3.5, stir evenly, and heat-roll the inorganic fiber paper Put the honeycomb core (300mm×150mm) into it and soak it for 5 hours, make it fully soaked, take it out and dry it, then dry it at 60°C for 24 hours, and cool it to room temperature; (2) Weigh 40Kg of crystalline aluminum chloride to dissolve In 120L of water, heat up to 60°C, under strong stirring, immerse the above honeycomb core in it, add lactic acid to adjust the pH value of the solution to 1.5, take it out after 18 hours of reaction, rinse with clean water and dry it, and then put it in an oven Dry at low temperature at 60°C for 24 hours, and cool to room temperature; (3) Place the rotor in an intelligent constant temperature sintering furnace, first slowly heat up at 200-300°C, and cool naturally, repeat 2-3 times, and ...

Embodiment 3

[0029] The inventive method comprises the following specific steps: (1) at room temperature, in a 250L circular plastic container, add 100L of water, then add 100Kg of water glass with a modulus of 2.8, stir evenly, and heat-roll the inorganic fiber paper Put the honeycomb core (300mm×150mm) into it and soak it for 2 hours to fully soak it, take it out and dry it in the air, then dry it at 60°C for 12 hours, and cool it to room temperature; (2) Weigh 45Kg of crystalline aluminum nitrate and dissolve it in 120 L of water, add gluconic acid to adjust the pH of the solution to 1.8, heat up to 40°C, and immerse the above-mentioned honeycomb core in it under strong stirring, rinse with clean water until the pH is neutral after 24 hours, take it out and dry it, and place it again. Dry in an oven at a low temperature of 60°C for 24 hours, and cool to room temperature; (3) Place the core in an intelligent constant temperature sintering furnace, first slowly heat up at 200-300°C, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com