Low-temperature plasma preparation method of nitride fluorescent powder

A technology of nitride phosphor powder and low-temperature plasma, which is applied in chemical instruments and methods, chemical industry, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

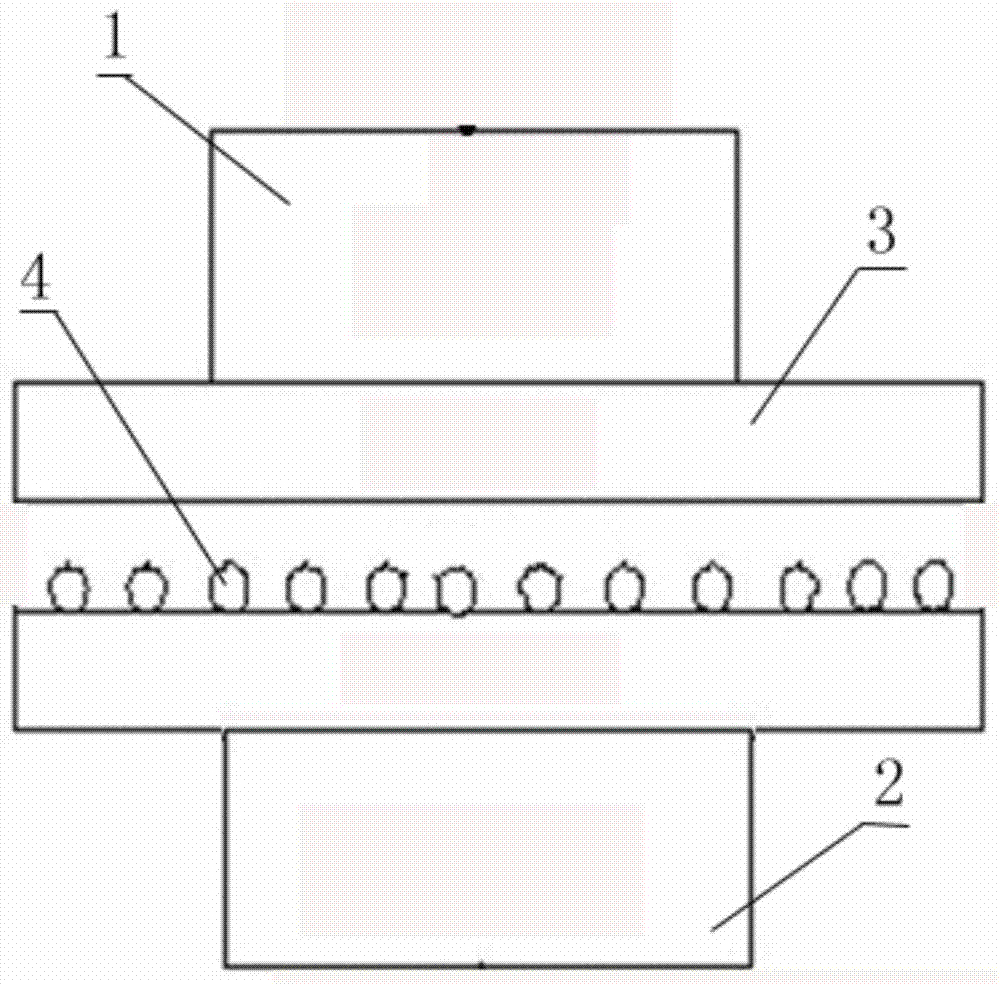

Method used

Image

Examples

Embodiment 1

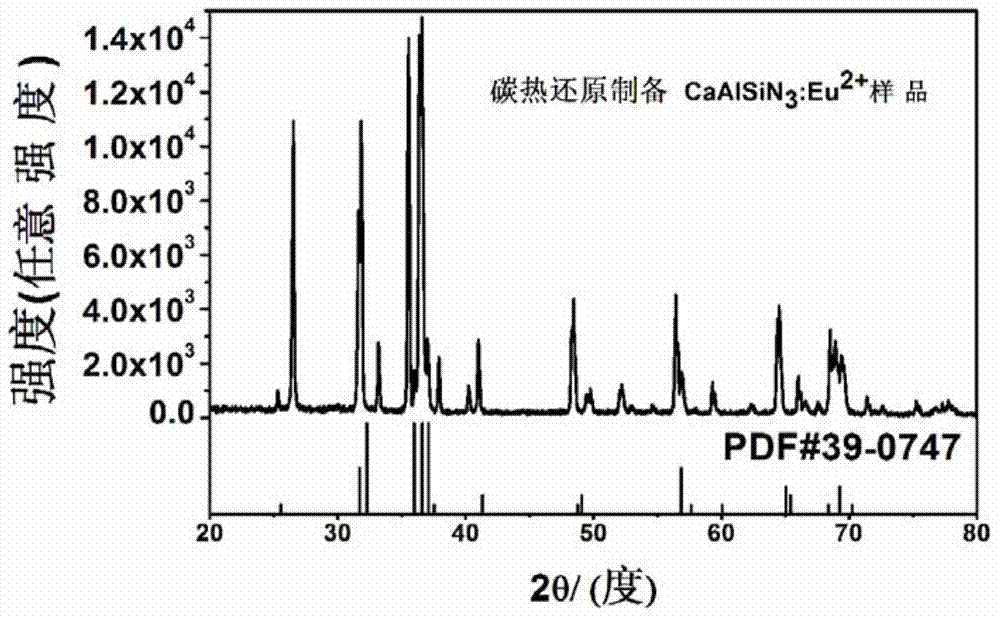

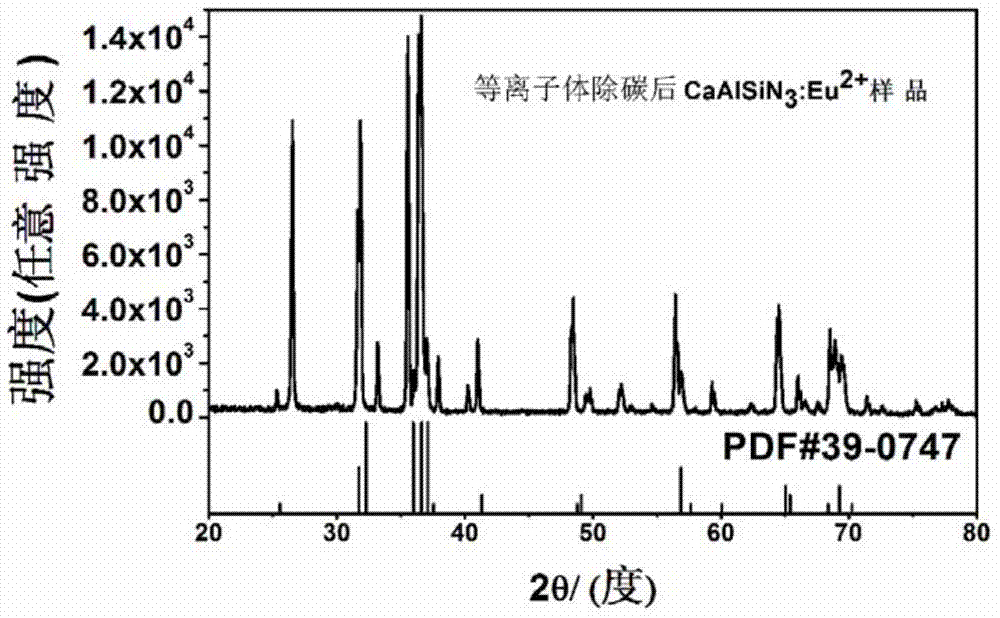

[0018] A low-temperature plasma preparation method of nitride phosphor powder, the chemical formula of the nitride phosphor powder is Ca 0.98 AlSiN 3 :0.02Eu 2+ , using carbothermal reduction to synthesize nitride phosphor materials under normal pressure, and then using low-temperature plasma carbon removal technology to remove residual carbon in the material, the steps are as follows:

[0019] 1) CaH 2 , AlN, Si 3 N 4 、Eu 2 o 3 According to the general chemical formula, the nano-graphite powder with a purity of 99.5% and an average particle size of 40nm is 0.98:1:0.33:0.01:1.3 in molar ratio, accurately weighed, mixed evenly, and then placed in a boron nitride crucible. Raise the temperature to 1550°C at a rate of 5°C / min in a tube furnace with a nitrogen-hydrogen mixture reducing atmosphere at a ratio of 92:8 at normal pressure and keep it warm for 6 hours. After naturally cooling to room temperature, Ca 0.98 AlSiN 3 :0.02Eu 2+ Nitride phosphor coarse material;

[...

Embodiment 2

[0023] A low-temperature plasma preparation method of nitride phosphor powder, the chemical formula of the nitride phosphor powder is Ca 0.96 AlSiN 3 :0.04Eu 2+ , using carbothermal reduction to synthesize nitride phosphor materials under normal pressure, and then using low-temperature plasma carbon removal technology to remove residual carbon in the material, the steps are as follows:

[0024] 1) CaH 2 , AlN, Si3N4, Eu 2 o 3 According to the general chemical formula, the molar ratio of graphite nano powder with a purity of 99.5% and an average particle size of 40nm is 0.96:1:0.33:0.02:1.4, accurately weighed, mixed evenly, and then placed in a boron nitride crucible. Raise the temperature to 1550°C at a rate of 10°C / min in a tube furnace with a nitrogen-hydrogen mixture reducing atmosphere at a ratio of 92:8 at normal pressure and keep it for 6 hours. After cooling naturally to room temperature, Ca 0.96 AlSiN 3 :0.04Eu 2+ Nitride phosphor coarse material;

[0025] 2) ...

Embodiment 3

[0028] A low-temperature plasma preparation method of nitride phosphor powder, the chemical formula of the nitride phosphor powder is Ca 0.96 AlSiN 3 :0.04Eu 2+ , using carbothermal reduction to synthesize nitride phosphor materials under normal pressure, and then using low-temperature plasma carbon removal technology to remove residual carbon in the material, the steps are as follows:

[0029] 1) Ca0, AlN, Si3N4, Eu 2 o 3According to the general chemical formula, the nano-graphite powder with a purity of 99.5% and an average particle size of 40nm is 0.96:1:0.33:0.02:2.2 in molar ratio, accurately weighed, mixed evenly, and then placed in a boron nitride crucible. Raise the temperature to 1550°C at a rate of 8°C / min in a tube furnace with a nitrogen-hydrogen mixture reducing atmosphere at a ratio of 92:8 at normal pressure and keep it warm for 6 hours, and naturally cool to room temperature to obtain Ca 0.96 AlSiN 3 :0.04Eu 2+ Nitride phosphor coarse material;

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com